Judge motor upgrades by their life cycle costs

As energy costs continue to rise, manufacturers are now, more than ever, looking for solutions to cut their energy usage. According to the U.S. Department of Energy, electric motor-driven machinery uses more than 2/3 of all electricity in industry. Due to tough economic conditions, companies may be holding off replacing older motors with more efficient designs. However, it’s important to remember that any motor upgrade should be evaluated by the motor’s life cycle cost rather than just its purchase price. Recent studies show that the initial purchase price of an industrial AC electric motor is less than 3% of its life cycle cost, with energy cost making up more than 97%.

|

View more content on PlantServices.com |

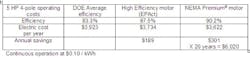

Simply replacing older motors with NEMA Premium efficient motors will have an effect on reducing energy costs. The chart below illustrates typical operating costs for an application powered by a 5 hp motor.

Although the energy savings from upgrading to premium motors is considerable, looking beyond simple motor replacement and analyzing the system will generally provide significantly more savings.

For example, if a right-angle worm speed reducer is used, changing to an inline helical or right-angle bevel reducer will have a significant effect on raising efficiencies, especially when paired with NEMA Premium efficient motors. Helical gearing technology delivers a wide range of ratios while maintaining 98% efficiency per stage of reduction. Helical-bevel right-angle gearing technology delivers efficiencies of up to 95%. Conversely, a single stage worm gear reducer’s efficiency can be as low as 60%.

The reason helical gearing is more efficient is a result of how the torque is transmitted through a rolling action. For a worm gear, torque is transmitted through a sliding action between the worm and the worm gear. This sliding action causes considerable friction and heat, which leads to greater efficiency loss than other types of gearing.

The overall system efficiency of the motor and gear box is the product of the individual efficiency of each item. The chart below compares worm gear reducer efficiency paired with a standard efficient motor, with a right-angle helical bevel (RHB) reducer paired with a premium efficient motor, both at 10:1 and 40:1 gear ratios.

With worm gear reducers, efficiency is lost at each stage of reduction, lowering overall system efficiency. Although upgrading to a premium efficient motor provides some benefit, the maximum energy efficiency can only be seen by pairing the helical reducer with a premium efficient motor.

Watts saved = HP x 746 x [1 – (existing worm gear efficiency / RHB Helical Bevel gear efficiency)]

Savings per year = (Hours Operated/year)(Power cost per kwh)(Watts saved) / 1000

Payback in years = Difference in hardware cost / Savings per year

Annual savings based on rate of $0.10 per kilowatt hour, 7,200 hours operation per year

Analyzing the motor/gear box combination and choosing both NEMA Premium efficient motors and high-efficiency helical gearing is the best solution for keeping energy costs to a minimum.

John Malinowski is product manager of AC & DC motors for Baldor Electric Co., Fort Smith, Ark., Contact him at (479) 648-5909 and [email protected].