As maintenance and reliability professionals, we must ensure that the assets that we are responsible for are operating as they were designed and installed to do. The hope is to move more toward predictive rather than reactive maintenance. It has been proved that when plants and facilities have a robust proactive maintenance program, that facility will operate more safely, with less downtime, and with improved product quality.

Maintenance and reliability professionals have tools at their disposal to use to monitor asset health on a routine basis. Similar to the way a doctor may use a stethoscope to listen to a patient’s heartbeat or a thermometer to measure the patient’s temperature, the maintenance and reliability professional uses condition monitoring tools that can help assess the health of a mechanical asset.

How does ultrasound work?

All operating equipment, most leakage problems, and electrical discharges produce a broad range of high-frequency sound. Ultrasonic instruments, sometimes referred to as ultrasound translators, sense and receive these high-frequency sound waves. High-frequency sounds are above the range of normal human hearing. Typically, sound waves sensed by human hearing are between 20 Hertz and 20 kilohertz, with average threshold of normal human hearing around 16.5 kilohertz (kHz). If a maintenance professional uses an ultrasound instrument with frequency tuning capabilities, the lowest frequency that it can be adjusted to is 20kHz. If the instrument being used is on a fixed frequency, it is usually centered around 38kHz. As a result, the ultrasonic instrument is already listening for sounds that are beyond the range of normal human hearing.

By nature, high-frequency sound waves are short-wave signals; therefore, they are very low-energy and tend not to travel very far from their source. This makes it easy for users of ultrasound technology to pinpoint the location of a compressed air leak or a particular mechanical problem. There are three main sources of ultrasound for typical plant/facility maintenance applications:

- Turbulence, such as a compressed air/gas leak to atmosphere, air in leakage (as with a vacuum leak), or a leaking valve or steam trap.

- Friction, created by a bearing lacking lubricant, which helps dampen the stress distribution between the bearings and the contact area. Along the same lines as friction, as a bearing begins to wear and show fatigue, there also are increases in high-frequency sound, even to the point of the user being able to hear and identify bearing fault frequencies such as inner race, outer race, cage, and ball-pass faults.

- Ionization created from electrical anomalies such as corona, tracking, and arcing in energized electrical equipment.

Ultrasound instruments give both qualitative and quantitative information. Qualitative information is given via the headset because of the ability to be able to “hear” what the bearing sounds like. Qualitative information also is given on the ultrasound instrument's display by way of the decibel (dB) level once contact is made with the bearing or once an air leak is detected. Some ultrasound instruments have the ability to view the FFT or time wave form of what the inspector hears in real time as the data is being collected. The ability to analyze and view FFT and Time Wave Form data of recorded ultrasound sound files brings about a more diagnostic use for ultrasound. Now, bearing fault frequencies can be identified, or a lack of lubrication condition can be noted. If ultrasound is being used for electrical inspection, corona, tracking, and arcing can be easily identified through FFT or time-wave form analysis of previously recorded ultrasounds.

Bearing inspection with ultrasound

Vibration analysis has long been the instrument of choice to use for bearings and other rotating equipment. More commonly, ultrasound is being used in conjunction with vibration analysis to help technicians confirm the condition of mechanical assets. Because of ultrasound's versatility, if a facility does not have a robust vibration analysis program in place, ultrasound can be implemented to detect early-stage bearing failures as well as other issues.

If the vibration analysis is performed by an outside service provider on a quarterly or monthly basis, ultrasound can be used during the interim. This will help the facility know the condition of some of the more-critical assets before the service provider enters the facility. The service provider’s time thus can be used more efficiently because the plant will know whether there are any eminent problems with the assets that are being monitored by ultrasound. The service provider can then prioritize work based on the ultrasound findings. Another scenario in which ultrasound may be used first over vibration analysis is with the monitoring of slow-speed bearings.

Slow-speed bearing monitoring with ultrasound is actually easier than you might think. Because most high-end ultrasound instruments have a wide sensitivity range and frequency tuning, it's possible to listen to the acoustic quality of the bearing, especially at slower speeds. In extreme slow-speed bearing applications (usually less than 25 rpm), the bearing will produce little to no ultrasonic noise. In that case, it is important to not only listen to the sound of the bearing, but also to analyze the recorded ultrasound sound file in spectrum analysis software, focusing on the time wave form to see if any anomalies are present. If “crackling” or “popping” sounds are present, then there is some indication of a deformity occurring. In bearing speeds above 25 rpm, it's possible to set a baseline decibel level and trend the associated decibel level readings over time.

To get the most out of an ultrasound bearing condition monitoring program, it's best to establish routes for data collection. Through this effort, maintenance technicians can set baselines and bearing condition alarm levels. This approach is called the historical method. Using this method, the inspector first establishes a route in the ultrasound software of the points where the data will be collected.

Once the route is created, the inspector loads the route into the ultrasound instrument. While collecting the initial data to build the history, the technician should record both the decibel level readings and the sound file recordings. It may also be prudent to collect the readings more frequently than is necessary to establish the history until the baseline and alarm levels are set. Once the baseline has been established, alarm levels can be set. For most bearings, an increase of 8dB above baseline represents a lack of lubrication for that bearing. An increase of 16dB above baseline means the bearing is in a failure mode this is beyond just a lack of lubrication. For slow-speed bearings, these alarm levels may need to be adjusted, because slow-speed bearings do not produce as much high-frequency sound as bearings that are rotating at faster speeds. The alarm levels for slow-speed bearings should be set according to what the initial historical decibel level trend shows.

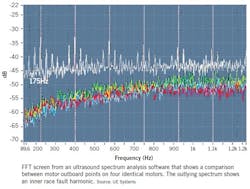

After the baselines and alarm levels have been set, it is necessary only to record the data or dB readings. From that point forward, a sound file recording is taken only once the point has reached either the low alarm or the high alarm. The alarm-level sound file recording can then be compared with the original baseline sound file. This is important for diagnosing the current bearing condition. In spectrum analysis software, technicians may also be able to compare the baseline sound file FFT to the current sound file or compare as many as four identical points on four identical machines.

Ultrasound-assisted lubrication

Studies have shown that the majority of premature bearing failures can be attributed to poor lubrication practices, whether in the form of using the wrong grease for the wrong application, lubricant contamination, or over- or underlubrication. Either way, most premature bearing failures result from lubrication failures. Ultrasound can be used to prevent over- and underlubrication related failures. In addition, with respect to using ultrasound for bearing lubrication, industry is moving toward condition-based rather than time-based lubrication.

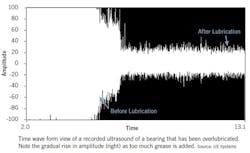

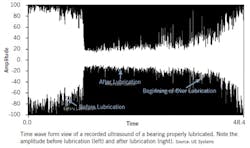

The concept is simple: It’s based off friction. When a bearing needs lubrication, there is an increase in amplitude or the decibel level. If a technician is using ultrasound to listen to the bearing while greasing and watching the associated decibel level on the ultrasound instrument, if the bearing needs grease, there will be a gradual drop in the dB down to a more normal or baseline dB. At that point, the technician should stop lubricating.

If the bearing is already sufficiently lubricated, the technician would start to see a gradual increase in the dB as grease is added. As more grease is added to an already sufficiently lubricated bearing, there will be an increase in both pressure and friction inside the bearing housing – and therefore, more noise. In this scenario, the technician should stop applying grease when an increase in dB is noted. If the technician is applying grease to a bearing and there is no change in the dB, then a follow-up inspection that includes recording the ultrasound sound file again or use of a complimentary technology such as vibration analysis is recommended to determine why the dB did not change during lubrication. If the bearing has physical damage or is in a failure mode beyond a lack of lubrication, then there will be little to no change in the dB while greasing.

[sidebar id="7"]

Airborne and structure-borne ultrasound instrumentation has become a must-have for any maintenance and reliability program. Because of its enhanced sensitivity and ability to detect slight changes in the amount of high-frequency sound produced by rotating equipment, ultrasound is ideally suited to detect early-stage bearing fatigue resulting from lack of lubrication in rolling element bearings. By translating the high-frequency sound into the low-frequency or audible range, these instruments let users hear, see, and diagnose bearing faults. Through ultrasound-assisted lubrication, bearing and machine life can be extended, and failures caused by over- or under-lubrication can be eliminated. Other advantages of ultrasound:

- High-frequency sound is very directional; therefore, problems can easily be located.

- The learning curve to become proficient at using ultrasound is much shorter as compared with that for other technologies.

- Ultrasound provides an early warning sign of impending mechanical failure.

- Ultrasound can be used in normal plant/manufacturing environments; background noise is not an issue.

- Advancements in ultrasound instrumentation and software allow for improved machine health and diagnostics.

- Airborne and structure-borne ultrasound can enhance efforts from complementary technologies or be a standalone tool used for a multitude of applications.

- Cost justification to implement ultrasound is easy given that ultrasound can quantify both the cost and CFM loss from compressed air/gas leaks to show a quick ROI.