You may have heard that compressed air is one of the most expensive utilities in an industrial plant. It's a fact that compressed air is a poor way to transmit energy to an industrial machine or tool if you want superior efficiency. That being said, it is unlikely that in the name of energy efficiency alone, you'll convert all of your industrial tools and equipment to direct-drive electric. Compressed air will never disappear from industrial plants; it is a very useful utility.

Compressed air system costs vary widely. This is because the efficiency of systems is often ignored, as there often are more important issues in running a system. (Chief among these are keeping the pressure at a constant reliable level and maintaining adequate air quality so that production runs smoothly.) Sometimes systems run at excellent efficiency; at other times, factors related to equipment characteristics, system design, flow characteristics, and maintenance levels can cause things to go very wrong.

The good news is you can do something about it.

This article outlines 13 ways to optimize your compressed air system for increased energy efficiency. Although certain points discussed in this article may relate just to the supply side of the system, or to the demand side, everything in compressed air systems is interrelated – items on the demand side can affect how the equipment on the supply side operates. In all cases, the best compressed air system efficiency occurs when both sides of the system are optimized at the same time by taking a holistic systems approach.

With regards to compressed air, what you and your employees don’t know will hurt you. It is very common to see surprised looks on people’s faces when they discover how much it is costing to run their compressed air systems, and how little mechanical energy they receive for the expenditure. Compressed air system awareness training is the best first step in optimizing your system by teaching you how to understand your equipment and how it is running. This knowledge is an important key to getting your costs in line.

The Department of Energy studied compressed air awareness training and found that attending the training helped more than 75% of attendees initiate positive action1. This action includes replacing inefficient equipment, changing maintenance procedures, and doing low cost/no cost measures such as leak detection and repair to reduce system waste (Figure 1). The study found that every dollar invested in compressed air training paid back at a rate of more than 80 times the initial outlay. More information on training for your staff can be found by visiting the Compressed Air Challenge website (www.compressedairchallenge.org).

2. Monitor your compressed air system

In order to get a handle on your compressed air system costs you must measure your system. A system that is not measured can’t be effectively managed. Creating a baseline is important in understanding the challenges involved in improving the efficiency, air quality, air stability and reliability of your system. To monitor you must measure key parameters like pressure, flow, power, and dew point over a period of time. Once collected, these data need to be analyzed to see if there are any issues.

For example, if your air compressors are rated at 18 kW input for every 100 cfm output, but system measurements reveal that your system is consuming 40 kW per 100 cfm, this is a pretty clear indicator that there is likely an efficiency problem. If you make adjustments to improve the situation, the system monitors will tell you if your efforts were successful, how much you saved, and if any other important system parameters have been affected by the change.

More and more factories are implementing permanent monitoring of their compressed air systems so that system parameters can constantly be monitored and adjusted. This is an exceptionally good practice, but good results can be still be obtained by bringing in temporary metering. The measurement and analysis of your system using the services of a qualified compressed air auditor can point you in the right direction.

3. Implement efficient compressor and dryer control

Are your compressors and dryers being controlled efficiently? In what control mode are they operating? It is rare to find a compressed air system operator with the answer to these questions. The control of the air compressors and associated equipment like air dryers is very important to the efficiency and reliability of the system.

With regard to individual compressor controls there are various common modes of operation, with some more efficient than others. Some common modes are start/stop, inlet modulation, load/unload, variable capacity control, and variable speed. Of these modes inlet modulation is the least efficient way to control any compressor that is running at part load, but may be acceptable if the compressor is always at or near full load. The variable speed mode is the most efficient way of controlling compressors at part loads but may not be the most efficient at full loads. If you have a mix of control modes, some thought and planning needs to go into setting up and coordinating multiple compressor systems.

A variety of control systems of varying complexity are widely available, and can be installed on compressed air systems to help coordinate compressors operation. This includes ensuring that correct compressors are running at any given time, that equipment is running efficiently, and that the system pressure is kept within specified limits. Implementing controls may be as simple as using what is already built into the onboard compressor control systems, or by the use of more complex external master control systems. There are system controllers now available that can also help you monitor your compressed air system to ensure your efficiency remains within acceptable limits.

Air dryer control is often a forgotten element in a system management effort, especially where desiccant style dryers are used. If your system has non-cycling refrigerated dryers, then you can reduce energy costs by making sure that any spare dryers are turned off if their associated compressors are not running. For desiccant dryers, there are dewpoint controls that can greatly reduce the dryer purge demand if the dryers are experiencing flows that are less than rated conditions. It is not uncommon to find desiccant air dryer purge making up the largest component of the compressed air demand in an industrial plant, in some extreme cases even more than the demand consumed by production machinery.

4. Boost efficiency via equipment replacement

The compressed air industry has changed for the better. Manufacturers are very aware that their customers are interested in energy efficiency, and so they have redesigned their equipment to be more efficient. When it comes time to do an expensive major overhaul on your old air compressors, keep in mind that the old equipment may not be up to present day standards. Rather than repairing an old inefficient compressor or compressor motor, it may be in your best interested to look at replacing the equipment with a brand new more efficient unit. This replacement can reduce operating costs going forward and pay for the replacement costs in a short period of time.

When calculating the operating costs savings and choosing what model of new compressor to purchase the Compressed Air and Gas Institute (CAGI) data sheets for the make and model in question can be used to compare various options. Most major compressed air companies have their CAGI sheets published on their websites. The data from these sheets can be used an inputs for your economic analysis in deciding to fix or replace and what compressor to choose. Data sheets are also available for refrigerated air dryers and may help you choose an efficient cycling dryer to replace an old non-cycling unit containing ozone depleting refrigerants.

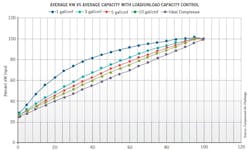

The use of storage receivers can improve your overall system efficiency in a number of ways. For example, using a main air receiver at the compressor room can make load/unload compressor control more efficient. In the past it was thought that lubricated screw type compressors only needed about one gallon of storage capacity for every cfm of rated compressor output. But this has proven incorrect if efficiency is the goal. The addition of 5 gallons of capacity per cfm or more has excellent benefits in reducing the effects of rapid cycling of screw compressors. Figure 2 shows the effect of adding storage which makes the compressor operate more closely to the “ideal compressor.”

Having significant storage at the compressor room also can help the compressors ride out transient high flow compressed air demands that might cause another compressor to start unnecessarily, or might require a compressor to run continually and inefficiently in unloaded mode to avoid low pressure events, both of which would needlessly increase power costs,

Well placed storage receivers located in industrial facilities on the plant floor can also be of benefit. Storage receivers can be placed near machines that consume short duration high flows of compressed air that might cause localized low pressure events that affects other pressure sensitive equipment. Use of storage to supply these transient events can smooth out these high flows so as not to cause the start of an extra air compressor or cause localized low pressure.

And if production machinery is being affected by localized pressure fluctuations, storage receivers protected by check valves can be installed to protect this equipment from short term transient low pressure events. This can prevent the need to increase the plant pressures to compensate.

The higher the discharge pressure, the more power an air compressor consumes. A general rule of thumb states that around 100 psi, and at a constant flow, the compressor power requirement increases about 1% for each 2 psi increase. Therefore, if this discharge pressure can be reduced some compressed air system savings can be gained.

Why is your system pressure so high? There could be a number of reasons, starting with end user requirements, pressure differentials, compressor control characteristics, etc. Often the operators of the system don’t know the answer to the question. Many times the pressure is set at a certain level because that is the rating of the compressor. It is important to know what your actual pressure requirements are, and realize that supplying excess pressure causes your compressors to consume more power than necessary, with typically no additional production improvements (Figure 3). If you find there is no good reason for high pressure, then lower it.

7. Improve air treatment efficiency

An air compressor produces hot, wet, oily air that must be conditioned so as not to contaminate downstream machinery or processes. The compressed air is dried using air dryers and is typically filtered in some fashion to remove contaminants. Compressed air treatment equipment can be a significant source of energy loss through purge loss (for desiccant dryers), electrical power consumption (refrigerated dryers), pressure loss (causing the compressor to consume more power), or through excessive drainage while removing the captured liquids from the system (Figure 4).

The selection of more efficient air dryers that use less power through efficient design, low- or no-purge flow, and/or lower designed pressure differential is a good energy efficiency measure. Airless condensate drains will reduce the compressed air waste that might be occurring if cracked open manual drains or timer style drains are normally used to expel liquids from the system. Every psi reduction in pressure differential or reduced cfm of wasted compressed air translates to less energy being consumed at the air compressors.

Undersized compressed air piping can cause a restriction to flow in compressed air systems, which forces compressor discharge pressures higher to compensate. Often the compressor room header system and distribution piping was sized many years ago. Over a period of time the plant may have grown and compressed air demands increased to the point where the original piping is too small. As part of the system optimization process, the compressed air piping pressure differential should be measured to determine if there is a problem. Piping modifications such as looping the system may improve things, or pipe size increases may be required. A good system should have no more than 10% pressure differential across the complete system from the compressor room to the end use piping drop. An excellent system will have no more than 2% drop.

A significant and important item to check is how much pressure differential exists between the piping drop and the actual end use of the compressed air. It is common to see the biggest pressure differential occurring in the “Dirty Thirty,” i.e. the last 30 feet of pipe. In that last section of piping, there may be undersized filters, regulators, lubricators, connectors, and hoses, all elements that can contribute to significant pressure differential. This differential can also be inside the production machinery itself.

When major pressure differentials occur in this section of the system, the discharge pressures at the air compressor end of the system must rise to compensate, increasing the power costs. Care and attention to sizing these components for low pressure differential at peak flows can often cost only a few hundred dollars, but yield thousands of dollars in annual savings at the air compressors.

On average about 25-30% of all the compressed air produced by the air compressors never makes it to the end user. If there is no leakage detection and repair program in the plant, this number can be much higher, and in extreme cases can up to 80% of the average air demand can be leakage. The repair of compressed air leaks is one of the easiest ways to gain energy savings in a compressed air system – all you need in most cases is a keen sense of hearing, some time, and a few wrenches. And if better tools are used, like implementing ultrasonic leak detection into a regular maintenance program, improved results can be achieved (Figure 5). A good target to aim for would be a leak level of 10% of the average compressed air flow.

It is important to ensure that the air compressors at the other end of the system are well controlled and have good turndown characteristics to get the most from leak repair. The reduction in leakage flow reduces the power demanded by the air compressors; also, this reduced flow will cause reduced pressure differentials across all the system restrictions.

11. Reduce or eliminate inappropriate uses

The inappropriate use of compressed air is easy to implement. With proper training, your personnel might realize that seeking the easy way may not be in your best interest due to the high cost of compressed air (Figure 6). There are many compressed air powered activities that can more efficiently be achieved using other energy sources. Some of these may be blowing, cleaning, cooling, pumping, creating vacuum, agitation, moving material, running air motors, and atomization of liquids.

In optimizing compressed air system, these potentially inappropriate uses of compressed air are identified and analyzed during the air system study. The life cycle costs then are compared with other methods of doing the same job. In some cases the use may not be completely eliminated, but can still be optimized by supplying lower pressure, turning off the use when not required, or redesigning it to run with less compressed air.

When equipment and processes receive compressed air at higher pressures than they are designed they typically consume more volume, but this may not result in an additional benefit to production. Air cylinders consume more air at higher pressure because it take more air to fill at higher pressure. Blowing devices use more flow at higher pressure because there is more force available to expel the air. All of this translates to higher total flow and resulting higher compressor power consumption.

Reducing plant pressure by reducing compressor discharge pressure can yield savings, but so will the use pressure/flow control devices that regulate the complete main plant pressure to only the minimum level required by downstream equipment. And local, well-sized regulators that have been carefully selected to regulate without excessive drop can reduce the artificial demand at individual end users.

And, for a Baker’s Dozen:

Compressed air optimization can definitely be implemented using low-cost or no-cost measures, but to achieve the best results, significant expenditure is usually required. Your local power utility or energy organization may support compressed air improvements with financial incentives if the work you are doing saves energy. Some of these organizations will support initial basic energy studies or more detailed full audits and even fund a significant part of a compressed air energy project. These organizations may also have information resources and technical support personnel to assist you in applying for these funds. It pays to ask about the possibilities for your plant.

References

1. U.S. Department of Energy, 2004. "Evaluation of the Compressed Air Challenge Training Program."