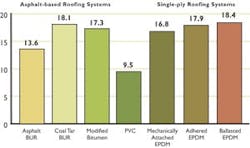

Challenging economic conditions have heightened interest in long-term roofing systems. As a result, life cycle costing considerations are playing a more significant role in roof specifications.Choosing a roofing system based on long-term performance can mean a higher installed cost. However, longer-lasting systems have proven to cost less over time because they are more durable and require less maintenance. Additionally, such roofing can lead to energy savings over the roof's life, depending on system design, facility type, location and other conditions.More building professionals recognize the value of investing in 20- or even 30-year roofing solutions. At the same time, there is a growing preference for thicker, more durable roofing systems featuring 60-, 80- and 90-mil membranes.Life cycle cost Over the years, various roofing industry professionals have introduced data suggesting that certain roofing systems offer a better life cycle cost than others. Although life cycle costing is a valuable economic tool, the range of variables involved complicates accurate calculations. In a study of more than 25,000 roofing systems in use between 1975 and 1996, Schneider and Keenan1 calculated the average service life for a variety of roofing styles (see Figure 1).

Determining whether service life should, or will, reach or exceed 20 years requires in-depth analysis. It's quite possible that, two decades from now, roof systems may be required to do more than keep water out of buildings. A roof installed today could be serviceable in 20 years, but might need to be replaced anyway to make way for new standards and technologies. For example, photovoltaics may turn future roofing systems into miniature electric power stations. Likewise, growing interest in "green roofing" may turn roofs into grasslands and gardens.

Know the time value of moneyMost canned life cycle cost calculations either assume a relatively low inflation factor, typically three or four percent, or measure cost in constant dollars. However, the real cost can be calculated only by determining the opportunity cost of money.In the case of a manufacturing company, the real cost of a dollar spent on roofing must be measured in terms of what return the same dollar could bring if it was invested in manufacturing equipment or other capital. In the end, the real cost of money exceeds the inflation rate.Consequently, the time value of money places a higher premium on the initial installed cost than originally expected. For example, the future worth of the $10,000 initial cost for a 20-year roofing system is $73,000 when discounted at 10 percent, $197,000 at 15 percent, and $528,000 at 20 percent.Roofing contractorsStudies and industry research are as important for accurate life cycle costing as is consulting a qualified, professional roofing contractor. Many contractors maintain databases to track the performance of the systems they install. Armed with information on similar sized or larger roofing systems, local contractors can offer insights to help determine what system would work best in each situation and what service to expect. In addition, these professionals can provide information on realistic maintenance costs that will help protect the initial investment.There are neither simple equations nor quick, sure-fire ways to calculate the exact roofing life cycle cost. An accurate estimate includes many factors, such as the time value of money and the expected investment horizon, which only an individual building owner can determine. Selecting products from a reputable manufacturer with a proven track record of performance, the ability to provide technical guidance, and a sound financial history is an essential first step. However, quality workmanship and professional maintenance affect the service life more than the system type itself.Most important, hire only experienced professional roofing contractors who are familiar with local conditions. Their first-hand knowledge is an outstanding resource for determining accurate installation costs and costs for the maintenance essential for keeping the system performing well over the long haul. James Hoff is vice president of marketing for Firestone Building Products Co. in Carmel, Ind. He can be reached at HoffJames@firestonebp.com and 800-428-4442.1 Schneider, K. G., and Keenan, A. S. (1997). A documented historical performance of roofing assemblies in the United States: 1975-1996. Proceedings of the Fourth International Symposium on Roofing Technology (pp. 132-137). Rosemont, Ill.: National Roofing Contractors Association.