Air knives remove particulates, water or other fluids from parts and surfaces quickly during a cleaning, cooling or drying process. While they're used in hundreds of industries and applications, one common application is parts washing. Parts washers frequently use air knives in several stages of the cleaning process. After a part has been through a washing spray or plating bath, an air knife minimizes "dragout," the amount of liquid adhering to the part. After rinsing, another air knife blows the fluid from the part and dries it.

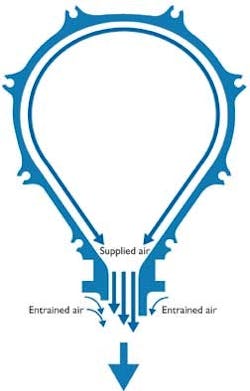

Using a compressor or blower as the air source, an air knife converts a low-pressure volume of air into a high-velocity, targeted stream of high-impact air, which exits the knife from a long thin slot. Air knives are designed in a variety of shapes and sizes, with a teardrop shape providing the most efficient airflow. In this configuration, the air stream attaches itself to the curved internal surface of the knife and entrains ambient air when it exits the slot (see Figure 1). Entrainment increases the total volume of air hitting the part's surface. Other shapes include a round and diamond tube, but flow efficiency through these designs is lower. The size of the parts being processed determines knife length. A variety of slot sizes allows for variability in the volume of air delivered (see Figure 2).

Free air

Figure 1. Air entrainment adds muscle to the blowoff.

Correctly specifying an air knife system reduces operating costs significantly, while improving production quality and cutting air consumption.

Improve production quality

Air knives produce a more steady and consistent air stream than open pipes, drilled holes or other air-control nozzles. A more consistent air stream, in turn, eliminates many quality-control problems, such as spotting or blotching, which can cause surface coating failure. Some air knives have a protruding leading edge that extends slightly beyond the air slot. This extended edge aids in air entrainment and maintains the integrity and consistency of the flow further downstream.

Choose your weapon

Figure 2. Air knives in various lengths and slot widths.

Air knives also provide flexibility in positioning the airflow, which is critical in blowing off irregularly shaped parts and those with holes and crevices. If water is not removed completely, rust, freeze-up and other product damage can occur. Here are a few tips for properly positioning air knives:

For cleaning applications, angle the knife 15 to 45 off the normal to ensure that contaminants are removed from the surface.

For blow-off applications, aim the air knife to "wipe" sideways across a moving target at a comparatively shallow angle.

Angle air knives like a snowplow above a moving conveyor so that the contaminant is forced off the belt, rather than backward onto the advancing surface.

Use adjustable mounting brackets on each air knife for ease of positioning.

Compressor vs. blower

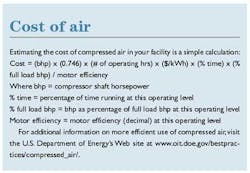

A properly selected, designed and maintained air knife system will reduce operating costs. Keep in mind that compressed air is one of the most expensive industrial utilities, often accounting for 10 percent to 30 percent

of total electricity consumed. Despite this fact, many facilities have no idea how much compressed air systems cost on an annual basis. A 100-hp compressor typically costs $30,000 to $50,000, depending on type and manufacturer, but annual electricity charges for the same system can reach $50,000. Annual maintenance costs add 10 percent of the system's initial cost to the bill.

The U.S. Department of Energy recommends low-pressure blowers as a more efficient alternative to compressed air for cleaning, cooling and drying. Using an air knife system, consisting of a low-pressure blower and an air knife, can save thousands of dollars each year in operating expenses.

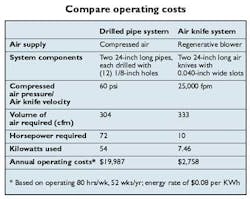

Table 1 shows typical system requirements and operating costs for a 24-inch wide conveyor application. It compares the annual operating costs of a blower-supplied air knife system to those of a drilled pipe system fed with compressed air.

Table 1. A pair of blower-fed 24-inch air knives uses a fraction of the electricity of a pair of drilled pipes on compressed air.

Reduce contamination

In addition to saving energy, blower-supplied air is much cleaner than compressed air. In one year of normal operation, a 100-cfm compressor can inject as much as one gallon of oil into the air stream. The economics of a blow-off system must include the potential cost for re-washing, should the air source prove to be contaminated.

For sanitary applications, including food, pharmaceuticals, cleanrooms and computer chip manufacturing, HEPA filters are used on blowers to provide absolute air filtration. HEPA-classified filters capture a minimum of 99.9 percent of contaminants larger than 0.3 microns in diameter. For reference, a dust particle is approximately 25 microns in diameter.

De-ionizing bars should be used in applications where products are sensitive to static electricity. De-ionizing bars positioned in the air stream remove static charges and neutralize surface charges on air-blown parts. The bars effectively eliminate particles in the air that could damage product appearance or quality or, worse, cause explosions.

Consider regenerative blowers

Low-pressure regenerative blowers provide a large quantity of clean, hot, dry air. They are excellent for air knife drying applications because their discharge is hotter than their inlet airtypically a one degree F differential for each inch of water pressure. For example, operating the blower at a discharge pressure of 50 inches water column implies the outlet air would be 50 degrees warmer than at the inlet. Assuming that the inlet air is 85F, the exhaust air temperature would be 135F.

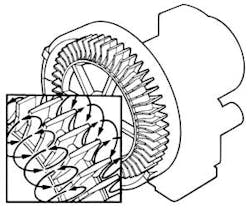

The compression space in a regenerative blower consists of a hollow, circular ring between the tips of the impeller blades and the walls of the housing (see Figure 3). The rotating impeller draws air through the inlet port into the compression space where centrifugal force moves it radially outward to the curved housing.

The action is described as regenerative because some air slips past each impeller blade during rotation, returning to the base of a succeeding blade for re-acceleration. This dynamic principle makes regenerative blower performance comparable to that of many multi-stage and positive displacement blowers.

Reduce noise

Noise from compressed air is recognized as an environmental hazard in the workplace. System capacity and design both affect noise levels. In general, higher flow rates, higher air pressure and the presence of obstructions in the air stream increase noise levels. Excessive noise and blocked holes, which frequently occur with open or drilled pipe, violate OSHA regulations. Compared to an open-pipe system, air control nozzles driven by compressed air or an air knife system driven by a regenerative blower can reduce perceived noise by more than 50 percent. Regenerative blowers produce less noise than centrifugal blowers. A muffler can reduce noise by between five and eight dBa and attenuate the high-frequency sound.

While the initial cost of an open pipe or drilled hole blow-off system may be low, operating costs, including energy use and inconsistent results, can quickly exceed the total cost for an air knife system.

Leakage improves performance

Figure 3. Regenerative blower impellers allow some air to slip past the blades and be re-accelerated by succeeding blades, which makes performance comparable to many multi-stage and positive displacement blowers.

Spec the unit

The following are key factors to consider when specifying an air knife system.

Compressed air and energy costsTo conserve energy and reduce costs, the U.S. Department of Energy recommends blower-supplied air for drying and blow-off applications. Conduct a compressed air system audit to identify the true costs of compressed air in your facility. Go to www.oit.doe.gov/bestpractices/compressed_air/ for more information.

Air velocityThe velocity required depends on the material to be blown off and can vary from 5,000 fpm to 40,000 fpm (60 to 400 mph). Viscous liquids, such as oil, are more difficult to blow off than water. When trying to remove solid chips from a part, material and particle size are key factors.

Surface texture and shapeSmooth, flat parts are easier to blow off than irregular, three-dimensional parts having holes and crevices. If water is not completely blown out of these hard-to-reach areas, product quality will ultimately suffer. An air knife provides the flexibility to direct the air stream into holes and crevices to remove water completely.

Working distanceIn general, the closer the better, with one to two inches being the ideal distance between air knife and surface. Use an inexpensive air velocity gauge to measure air velocity at a specific distance from the knife.

CleanlinessIf part cleanliness is critical, consider blower-supplied air, which is cleaner than compressed air. Also consider using filters or de-ionizing bars to remove airflow contaminants.

Material of constructionMaterials should not be subject to environmental corrosion or restrict the airflow. Typical air knives are constructed from anodized aluminum or stainless steel. When specifying an air knife system, be certain that the fluid being blown off won't attack the knife material.

Noise levelsBoth capacity and system design affect noise levels. Regenerative blowers produce less noise than centrifugal blowers and open pipe systems. Mufflers are available to reduce noise between five dBa and eight dBa and to remove high-frequency sound associated with moving air.

Jon Barber is an air knife specialist at Spraying Systems Co. in Wheaton, Ill. He can be reached at 800-957-7729.

Figures: Spraying Systems Co.