Build and benefit from a skill-based pay system

Editor’s note: George Simonoff, CMRP, and Bob Kazar, CMRP, serve as director of reliability and director of reliability systems, respectively, at Los Angeles-based The Wonderful Co. Kazar additionally was chairman of SMRP from 2015–2016. At a reliability conference in Las Vegas last spring, they gave a presentation on craft skills development and the craft skill competency matrix. Following is an edited version of that presentation.

A common complaint when it comes to compensation is that the process for setting an individual employee’s pay is often subjective and arbitrary. In addition, the skills required to be successful in a given position frequently are poorly understood and don’t receive re-evaluation to see how they can be improved. Our company wanted to take the subjectivity out of pay increases and give employees a line of sight into how they could grow within the company; we also wanted to define the skills needed for the business to be successful. To that end, we developed a craft-skill competency matrix, consisting of a variety of “skill blocks.” This matrix now serves as the foundation for The Wonderful Company’s skills-based pay system.

A skill-based pay system rewards employees for demonstrating their use of defined skills that deliver on a business need. First, the business needs are defined; then the skills are defined based on the task; then, in our case, skills are bundled together into what we call skill blocks – groupings of competencies that are related by level and by trade. Our employees receive pay based on acquiring these skill blocks and continually honing job-related skills.

Each skill block contains a list of tasks to be demonstrated for qualification purposes. The blocks are broken down into categories, and the company tracks progress for each employee for completion and advancement to the next level. Each level builds on the skills of the previous level.

Skill blocks also incorporate standard qualifiers such as attendance and job performance history. When we post open positions internally, the blocks that an employee has attained determine whether the employee is qualified to apply for that role. If, for example, the position was categorized as Lead Level 2, interested individuals would have to have attained the Lead Level 1 block to be eligible to apply for the role.

What this allows our company to do is to define the skills required to be successful at a particular level and then give employees the opportunity to advance – and a structure for progressing – onward through the ranks. We have identified good employees and developed longstanding relationships with them in a way that impacts retention, and we have found it to be a good investment on both sides.

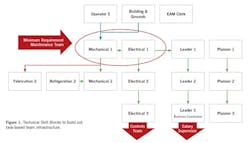

In Figure 1, you can see our technical skill blocks. This is how we have grouped competencies required for many of the required roles within the facility. The Mech1 skills block is the entry point as a technician. There are qualifying roles that would allow an employee outside the maintenance department to apply for a maintenance role starting at the Mech1 skills block; an Operator 5 level is an example.

A person who has reached qualification for an Operator 5 role has specific basic skills of a maintenance technician. We’ve taught that person about safety and operations and the use of certain hand tools. The person would have been performing specific PMs, and higher-level PMs than other operators on the floor. For the building and grounds folks, they’ve been working on lighting systems, for example. Mechanical and electrical prequalifiers are the basics for anybody coming onto the team, and progressing upward means acquiring additional mechanical and electrical skills. And once we attach a dollar wage to an entry point, the rest of these blocks add up to increase the employee’s wage, minus standard cost-of-living increases.

For the sake of easy math, let’s say that a Mechanical Level 1 position starts at $20 per hour. Any of the Level 1 skills that this person picks up would be worth a dollar per hour more. Adding the Electrical 1 skill block would lift the person to $21 per hour.

Jumps to Level 2 and Level 3 are worth an additional $3 per hour. A person who has the Mechanical 1, Electrical 1, and Electrical 2 skill blocks would earn $24 per hour. This provides a path for growth in our technical teams from the shop floor and onward into leadership roles. With clearly defined entry points to each level, it allows us to be consistent in compensation both for current employees who are acquiring new skills and with new hires who are coming through the door.

For a refrigeration tech, the required skill blocks are M1, E1, and M2. The salary progression would be $20 per hour to $21, $24, and then $27. The compensation-setting process becomes very objective, and we can plan the business around what we think are the skills required to run a facility. For example, we need two fabricators, or we need three refrigeration techs, or all shift mechanics must be an M1. We can more effectively formulate our current team and better create positions we will need that people can grow into.

Defining the skills blocks content has been a large undertaking, and we are still completing this work. We have defined several to date – M1, M2, E1, E2 – and we have Lead levels 1, 2, and 3 built. Also, we have Planner 1, Planner 2, and Fabricator.

There were two failed attempts at building these, given how large the scope was overall. On the third attempt, we used a consultant to help create supporting documentation, with plant and corporate folks building task definitions. We also used Lean tools, 5S specifically, to organize and straighten the content into a usable format.

Each block was written as a grouping of similar skills at the appropriate level. For example, we can say, “An M1 has demonstrated competency in and can perform the following types of things.” For example, we want the person to have fundamental lubrication principles to be able to identify general abnormalities with equipment during visual inspections. We have a lot of conveying systems in the plant as well, so we sought the ability to install/tension belts properly, apply basic knowledge of alignment, apply basic knowledge of fasteners, hardware grades, and torque settings, and then be able to use basic uptime inspection tools such as thermal imagery and ultrasound technologies.

We identified all of these fundamental tasks and abilities, and we placed them into the blocks. We then honed these, matching them to the kinds of capabilities we sought, in order to place them logically into an appropriate bucket.

We had our matrix, and then we added these Planner 1, 2, and 3 levels. In effect, we created a standard for the corporate team for developing training and education appropriate for all facilities. In addition, in our final iteration, we defined skills that were specific to our plant. General skills – ones like torquing, tensioning, and alignment – are things we can teach and help support other plants in teaching. Other facilities can build in skill blocks that are specific to their plant and equipment.

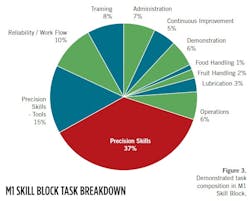

How do the skill blocks break down? Figure 3 demonstrates the category of tasks of the Mech1 skills block. Several of the tasks are millwright and precision skills, but several are soft skills, such as communication. These aren’t wrench-time-related but are essential to shop-floor success.

George Simonoff has 25 years of industry experience serving in various roles that contribute to operations excellence. Currently he is senior director of reliability for The Wonderful Company. He has been a practicing CMRP for 18 years.

Having said all of this, training is another big step for us, because now we’re asking for specific skills and cutting out the other nonvalue-added portions that may come with a traditional community college approach. This has forced us to develop training internally and gear it specifically to the tasks defined in each block. It’s admittedly a fine line as far as how much theory you strip out to emphasize strictly skills development. Given the accelerating pace of modern manufacturing, how we educate our employees has to be rapid and effective, just as with everything else that we do.

In building our training, we’ve leveraged in-house and out-of-house resources to give us the skills we need. We continue to refine what that looks like, too, by incorporating a mix of e-learning, demonstration of hands-on skills, and job shadowing. We also have employees perform tasks alongside someone who may be at a higher level so that person can coach them through it. This mix helps them retain the skills they’re learning and then use them when they’re assigned to work out on the floor.