You get emails and see articles every week that tell you that predictive maintenance – and maybe specifically vibration monitoring – will save you maintenance time and dollars. You’ll move from reactive to predictive maintenance, and planning and scheduling will be more efficient, these say. Your machines and your plant will run better, and you will sleep better at night. A predictive maintenance program promises all that and more, right?

Part 1 – How to start a vibration route

It’s true: A good program can deliver all of those things. But how do you start? And how do you get to “good”? The first step is to have a plan with established goals and expectations. Some of the questions you need to answer are:

Are we committed? This may take months to implement!

PdM programs don’t happen overnight. We will talk about this later, but do you and your team have stick-to-it-iveness? From the perspective of vibration analysis for PdM, there are too many (expensive) vibration monitors out there, purchased with good intentions, that are now collecting dust.

Do we have the resources to implement a vibration data collection program?

You need a technician(s) who wants to be a part of a predictive maintenance program. He or she must be trained (more about that later, too). The technician(s) must have a basic understanding of the machines to be measured so that he or she can better apply the technology.

Do we want to contract a third party to perform data collection or vibration analysis or both?

Third-party providers can collect and analyze data. Taking advantage of cloud-based platforms and other online solutions, you can collect the data and send it speedily to a third party that will perform analysis and offer solutions. You can mix and match third-party services to build your program with good results. Your intention might be to use the third-party service as a training resource, with a plan for your organization to take over the program when you and your team are ready.

Should we use portable data collection or install vibration sensors for remote monitoring?

This decision can be made only after you have performed a criticality analysis and a resource analysis. Once you understand the criticality of your assets and know how a failure will affect downtime and costs, you will be better able to make this decision.

Part 2 – Foundations

Any good plan has a good foundation. You must understand not only what you will measure and where you will measure but also why will you measure.

Start with a list of your assets. Again, use a criticality spreadsheet to determine which assets can shut down the plant, which assets cost a lot of money to repair, and which assets take a long time to repair. Another part of this evaluation should be to identify which assets fail most often and need to be targeted.

The next step after you have your asset list and you understand each asset’s criticality is to identify the failure modes that most frequently cause that asset to fail. This will help you know what to look for when performing analysis and visual inspections. Understanding an asset’s failure modes will help you know which technologies will be best to apply – vibration, lubrication monitoring, oil analysis, and thermography are best applied once you understand the failure modes of any asset.

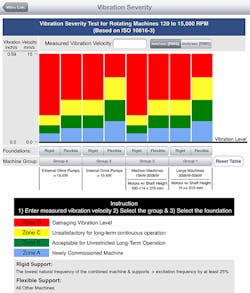

The next step is to set alert and alarm levels for each asset using ISO standards to see when an asset exceeds recommended vibration levels.

Once you have all of your foundation data, it’s time to get down to business.

Part 3 – Let's get started

Start small! Now that you have a long list of assets with foundation information, let’s talk about how to start building routes. One of the most common reasons that condition monitoring programs fail is that people try to do too much too soon. It is like eating an elephant – you have to do it one bite at a time.

Let’s go back to our criticality analysis again. You can perform criticality analysis not only on individual assets but also for plant areas and processes.

Where will you get the most results in uptime and cost savings by applying predictive maintenance technologies?

If you are not dedicating a full-time resource to your program, then start by developing small routes that can be completed in a couple of hours. Make this a daily or a weekly task that can be completed in the time allotted. It’s frustrating to try to perform a route and then be called away for a maintenance task and never find the time to get back to it.

If you don’t make this a priority, then neither will your employees.

Part 4 – I've got data...now what?

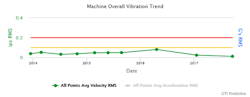

A seasoned vibration professional once told me, “The trend is your friend.” The most important part of trending is seeing what changed. When something changes, we know it is time to act. Actions include monitoring more closely, alerting operations to monitor on-site, identifying the fault and, when the time comes, planning and scheduling the asset for repair. Once a repair is complete, make a note in the trend data that explains the fault and the repair for future issues.

When an intervention is required, use your vibration analyzer to determine the root cause. Alignment, imbalance, looseness, etc. are symptoms. Determining the root cause will ensure that you know what caused the symptoms so that you can better prevent the failure from repeating in the future.

Advanced tools will notify you whenever the trend is changing and how fast it is changing without looking at every measurement.

Don’t over complicate your vibration program. You can get great results by keeping it simple in the beginning and growing as your capabilities improve.

Part 5 – Training, documentation, commitment

Aristotle wrote, “Excellence is an art won by training and habituation.” Everyone involved needs to be trained not only in how to perform these essential tasks, but also why it is important to do them. Documentation standards will challenge team members to do the work correctly, every time. Commitment to following through will keep the program going and produce long-term results.

Training is readily available in our industry. Manufacturers and consultants offer on-site and classroom training for all of the disciplines we will be discussing. Do your homework and investigate your training options. Make sure you know what you want and what you are getting.

Do you want training on how to use a certain product, or do you want training to teach the entire process? Ask the potential trainer for a course synopsis and make sure it covers the topics you need. Ask the trainer whether he or she is a practitioner.

Documentation is essential. It has been said that people only respect what others inspect. Training helps ensure that things are done correctly and on time. Documentation can serve to highlight areas where more training is needed. It also provides a maintenance history for each piece of equipment that can be valuable when troubleshooting a particularly bad actor. Further, documentation provides proof that the task was actually performed.

Commitment means achieving buy-in from every level – from the maintenance reliability professional to management – to making sure that tasks are performed to schedule, proper training is provided and received, and the program isn’t ended prematurely if results do not come fast enough. There are short-term benefits to be gained from using these tactics, but in the end, this is a long-term strategy.

Part 6 – Keep it going

Predictive maintenance programs are a lot like gym memberships – once your effort ceases, it is really tough to get going again. To keep your program going, heed the following:

Paul Berberian is a condition monitoring specialist and a vice president at GTI Predictive Technology.

- Make the commitment to succeed

- Ask for help! Third parties (and their partners) may have the tools and talent needed to help make your vision a reality

- Measure what needs to be measured, adding assets as your program grows

- Understand your machines to get the best results

- Build on a strong foundation

- Start small – target the areas where you will get immediate results in time and money.

- Trend, trend, trend

- Never stop training yourself and your team!

Finally, make a big deal internally out of any success story. We always reward the firefighters. Start rewarding the techs who prevent fires. Make sure that plant management and operations team members are aware of any success. The best way to get additional support, money, and resources for your maintenance programs is to demonstrate and document success.