The most frequent concern about high current with a three-phase motor is high no-load current. But the broad issue of high no-load current isn’t the only three-phase motor issue to which plants should pay heed: High current with load and lower-than-expected no-load current are potential areas of concern, too. Let’s explore the sources of all of these.

High no-load current: Motor not rewound

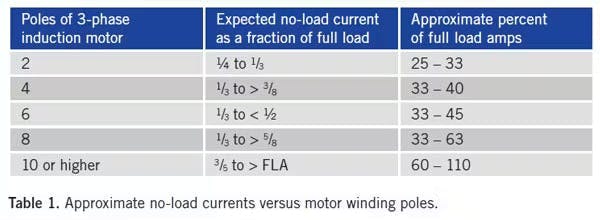

One situation in which higher-than-expected no-load current can occur is with reconditioned motors. Although some motors with no-load currents above or below the guidelines shown in Table 1 may still be satisfactory, motors with no-load current outside of these ranges warrant further analysis.

When no-load current is high or low, consider the actual test operating voltage versus the motor’s rated voltage. If the applied voltage is not within 10% of the motor’s rated voltage, then the no-load current can be much higher or lower than expected. For example, test-operating a motor rated 200 volts on a 240-volt supply system is almost certain to result in relatively high no-load current.

A misconnection also can cause unusually high or low no-load current. For example, consider a 12-lead single voltage motor intended to be connected parallel-delta (Figure 1) for 460 volts. Because most 12-lead motors are dual-voltage, the motor could be mistakenly connected series-delta (Figure 2) for operation at 460 volts, which would result in exceptionally low no-load current. The solution is to connect the motor for parallel delta.

Another possible issue with a 6-lead or 12-lead wye-delta motor is misconnection with a delta instead of a wye. Although most of these motors operate with the delta connection, some use the wye connection. If that is the case and the motor is operated with the delta connection, the no-load current will probably far exceed the rated current.

A good practice with 6- or 12-lead wye-delta motors is to test-operate them in the wye mode and check no-load current. If the current is exceptionally low, reconnect for delta and repeat the no-load test. If, however, the no-load current appears normal in the wye connection, verify the correct connection for the application. If the connection should be delta, there is an error in the winding.

Motor with no nameplate

A less-common scenario is a motor without a nameplate that has a relatively high no-load current for an assumed power rating. In this case, first determine the frame size from a NEMA dimensions chart by measuring the width from bolt-hole center to bolt-hole center of the motor feet (front to back and side to side) as well as the height from the base to the shaft center.

Next, determine the number of poles. At 60 Hz, the number of poles is equal to 7,200 divided by the no-load rpm, rounded to the nearest integer. For example, if the no-load speed is 1,798 rpm, the motor has 4 poles (7,200/1,798 = 4.004 = 4).

The frame size and number of poles/speed can be used to closely estimate the motor power rating. If the new estimated power rating differs from the assumed power value, use the new rating to evaluate the no-load current.

High no-load current: Rewound motor

The most common causes of high no-load current after a motor is rewound are incorrect winding data and stator core damage.

Incorrect winding data that increases the magnetic flux levels as compared with design levels will result in increased no-load current. Although the effect on full-load current is not nearly as significant, the higher flux levels also will result in higher starting current, which can trip protective devices. In extreme cases, this can cause contactors to blow open or weld closed. Service centers can usually confirm that the winding data is correct by following good practices, such as comparing the data to a winding database or using a computer program to calculate and evaluate winding magnetic flux densities.

Service centers can also evaluate the condition of a stator core by performing a core test that evaluates core loss (watts per pound) and hot-spot versus ambient temperature rise. The results can be compared with industry norms or cores of similar motors.

High current with load

Probable causes of high current with load include mechanical overload, excessively high magnetic flux densities and, less frequently, an open rotor. An error in winding data that results in lower-than-design-level magnetic flux also can cause high current with load.

If inspection of the driven equipment does not indicate a mechanical cause for motor overcurrent, it may be necessary to load-test the motor to confirm that it has acceptable current at full load. Use caution when evaluating actual motor current versus rated current. The NEMA MG1 motor and generator standard allows a ±10% tolerance on rated full-load current. For example, if the nameplate rated current is 100 amps, the actual current could be as low as 90 amps (-10%) or as high as 110 amps (+10%) and still be acceptable.

A winding with magnetic flux levels at least 10% greater than the original design densities will usually draw higher-than-rated current at full load and will have higher-than-typical no-load current. A method of checking the performance of a “magnetically strong” motor such as this is to measure the exact rpm at full load. If it is significantly above rated speed, the motor may be magnetically strong and therefore have relatively high flux densities, possibly causing magnetic saturation and higher current. Determining whether the speed is significantly high requires further investigation and some basic calculations.

The NEMA MG 1 standard allows 20% variation in motor slip rating at full load. The slip is the difference between synchronous and rated speed. For example, if a 4-pole, 1,800 rpm synchronous speed motor has a full-load rating of 1,750 rpm, the slip would be 50 rpm (1,800 – 1,750); 20% of the slip would be 10 rpm (0.2 × 50). Therefore, the actual speed could be between 1740 rpm (1,750 – 10) and 1,760 rpm (1,750 + 10). A speed greater than 1,760 rpm would be considered significantly high and could indicate a magnetically strong winding design. Before drawing any conclusion, check the line-to-line voltage. If it is more than 10% above the motor rated voltage, it could be the cause of the high full-load speed and possibly the high current.

An open rotor can cause a pulsation in the output torque of a motor as the open rotor bar passes under each phase of the motor winding. The net effect is a reduction in the steady-state output torque; on average, the motor also draws higher current that often pulsates. If an open rotor is suspected with an assembled motor, perform a single-phase open rotor test. This test consists of applying about 1/6-1/4 of rated AC voltage, or variable voltage up to a current value of 75%–125% of rated current, to two line leads of an induction motor while slowly turning the rotor manually. Use a clamp-on ammeter to measure any fluctuations in current. A current fluctuation greater than 3% for a used rotor or 1% maximum for a new rotor usually indicates a broken bar; it will occur each time the open bar passes under an energized pole.

Just as excessive magnetic flux can cause high current with load, so, too, can insufficient flux. The torque capability of a motor is proportionate to the square of the magnetic flux level. For example, if the winding flux is 10% lower than the design flux, the torque capability of the motor will decrease to about 81% (0.9 × 0.9 × 100 = 81) of rated. A motor with a power rating of 100 hp would therefore behave as if it were designed for 81 hp. At full rated load it would be overloaded by about 23% (100/81 × 100) because of its magnetically weak winding. The results would include overcurrent and operation at much lower-than-rated speed.

Know what you're dealing with

Electric motors that draw higher than expected current either at no load or with load are common issues. Determine if the high current is limited to the no-load condition and, if so, whether the motor was rewound. Then follow the steps described to find a solution. Similarly, if the high current condition is with load, or both with load and no-load, follow the guidance provided above.