Lubrication best practices for compressors and centrifugal pumps

Proper lubrication of compressors and centrifugal pumps is a subject that’s both vast and of great importance. Because uninterrupted long-term operation is especially critical in oil refineries and petrochemical plants, we’ll focus attention here on issues observed in fluid machines such as gas compressors and centrifugal process pumps in this specific industry sector.

Heinz P. Bloch, P.E., is owner of Process Machinery Consulting in Westminster, CO, and the author of close to 700 articles and 20 books, including “Pump User’s Handbook — Life Extension” and “Practical Lubrication for Industrial Facilities.” Some of his work has been translated into five foreign languages, and Bloch has seven machinery-related patents to his credit. He is an ASME Life Fellow and was one of the original Texas A&M University Pump Symposium advisory board members. Contact him at [email protected].

When you examine design and fabrication in greater detail, you realize that flow, pressure capabilities, and construction materials are given far more attention than lubricant application, lubricant selection, and bearing protection. A similar observation can be made on mechanical seal selection, where savings in initial cost and the desire to link up in a vendor or supplier alliance often crowd out the quest for true long-term reliability achievement.

Introduction to risky components: Oil rings. Reliability-focused user companies are intent on designing out maintenance and avoiding—even disallowing—subassemblies or machine elements that are prone to malfunction. Figure 1 serves to make the point by showing widely used oil rings as originally installed (left image) and as removed from a bearing housing (right image) after leading to a bearing defect. Unless oil rings are designed and manufactured with heat-stabilized (annealed) materials, they will not remain sufficiently concentric to preclude slipping and skipping on shafts. An out-of-roundness exceeding 0.002 inches (0.05 mm) is not considered acceptable for oil rings. That fact alone mandates manufacturing and intermediate stress-relieving procedures which, by their very nature, exclude the use of lowest-cost products.

These components must also be installed and maintained with above-average care. Unless shafts are truly horizontal, oil rings will tend to run downhill. When they do so, they will likely contact a stationary surface; the abrasion seen in the right image of Figure 1 will result. Oil contamination cuts short the life of any bearing. Finally, most oil rings are designed for a narrow range of lubricant viscosities—typically ISO VG 32. They will slow down in thicker oils and feed progressively less oil into the bearing.

Although millions of oil rings continue in successful long-term service, millions of others last only a relatively short time. Success is linked to the care and diligence used in carrying out the many critical design, fabrication, and installation steps that allow oil rings to function properly. Where the needed diligence is lacking, oil rings can be a source of malfunctioning lubrication and frequent bearing distress.

In process pumps installed in U.S. oil refineries and other mature industry facilities, a bearing life of six years is typically reached without difficulty. But suppose an oil refinery is indifferent to the need for knowledge-based implementation of oil-ring-related procedures and work processes. If that refinery were to obtain only a three-year bearing life for its pumps, the facility would experience twice as many pump outage events and twice the associated costs. Regrettably, many such pump owners have let their three-year bearing replacement intervals become the accepted “new normal.”

Introduction to risky oversights:

(a) Oil degradation. Although designing and manufacturing bearing housings for fluid machinery with accuracy and forethought is the manufacturer’s responsibility, pump users must know the delivered product. In other words, savvy users will insist on reviewing the pump’s cross-section views so as to identify oversights or shortcuts taken by the pump manufacturer. Premature bearing failure can result if the manufacturer neglects to provide drilled passageways or some other escape route for the lubricant that gets trapped. Oil trapped in these spaces will overheat and turn into a tarlike sludge.

Balancing holes also are vital to ensure that the air pressures on each side of a rolling element bearing are equalized. If these pressures aren’t the same, lube oil throughflow may be hindered, or in some cases, oil may leak from the bearing housing.

Figure 1. A new oil ring (left) will fail unless properly heat-treated and installed. At right, serious abrasive wear has occurred due to lack of concentricity and/or careless installation. Source: TRICO Mfg. Company

Introduction to risky oversights:

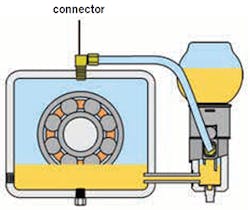

(b) Oil deprivation. A prominent manufacturer of constant level lubricators first marketed its “oilers” in 1917. In recent decades, reliability-focused users have insisted on pressure equalization between the air space in the bearing housing and the air space surrounding the angled tube protruding from the oiler bowl into the lubricator body, as seen in Figure 2. Unless there is this pressure equalization, it is possible that the oil level inside the bearing housing will be below the oil level in the die-cast lubricator body. Should that be the case, the oil level in a bearing housing not equipped with the balance line shown in Figure 2 might decline to a level where oil will no longer reach the rolling elements.

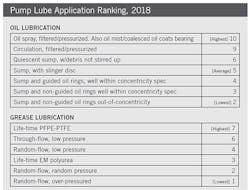

Experience-based rankings for general guidance. In the early 1980s, a major bearing manufacturer published a ranking list for industry. A number of different oil and grease application methods were listed in the bearing manufacturer’s order of preference. Years later and with the advent of improved lubricants, the author reshuffled these rankings. A provision was added to link these recommendations to process pumps and their electric motor drivers only. The rankings shown in the top half of Figure 3 should be assumed to reflect oil-lubricated pump bearings, while those in the bottom half reflect the author’s experience with grease-lubricated electric motor bearings only.

Figure 2. Constant level lubricator with pressure equalization line between bearing housing and space surrounding angled tube in lubricator housing. Source: AESSEAL, Inc.

Circulating lube oil systems and oil mist were recognized as the best choice in the rankings of both 1980 and 2016. The availability of a small, pre-engineered circulating lube system derived from pressurized dual mechanical-seal technology (Figure 4) should be emphasized, as should advances in plantwide “closed” oil-mist systems.

Figure 3. Bearing manufacturer’s oil and grease confidence ranking.

Small oil-mist systems serving as many as four pumps are in highly successful service. Upgrading to these small systems has solved nasty lubrication problems on critical hot service pumps that were originally furnished with oil rings or, in at least one case, too small an oil sump in a newly designed pump. The remaining rankings, in descending order from 8 to 1, are largely self-explanatory and should provide useful guidance.

Finally, a few comments on synthetic lubricants. Synthesized hydrocarbons are long-chained molecules. The lube manufacturer/formulator must choose from a half-dozen base stocks and a seemingly inexhaustible combination of additives. Here are six machinery applications where the higher cost of synthetics is justified over the use of mineral oils:

- Automotive lubes. Properly formulated synthetics are selected for their low friction and extended drain intervals. The greatly improved high-temperature tolerance of these oils may mandate their use in high-performance engines.

- Rolling element bearings. Over time, rolling-element bearings tend to develop microcracks; vibration severity often increases as rolling elements contact the microcracks. Switching to an appropriate synthetic will fill the microcracks; vibration severity will be thereby reduced or altogether eliminated.

- Gearboxes. Gearboxes and cooling tower fan gears will run cooler and live longer with good synthetics.

- Closed-loop oil-mist lubrication units. These allow collection and reuse of oil over extended time periods. Significant operating and maintenance cost savings have been realized with synthetic lubes in closed units.

- Reciprocating compressor cylinders. Here, too, greater uninterrupted run lengths have been documented with synthetics. Good formulations have greatly extended valve and piston ring/rider band life.

- Oil-flooded screw compressors. These benefit significantly from the many positive lubricant performance trends achieved with synthetic formulations. Switching to superior synthetics allows for higher compression ratios and, typically, fourfold run extensions before oil changes are needed.