Paper Converting Machine (PCMC) in Green Bay, Wisconsin, builds machinery for a variety of industries including tissue converting and packaging, flexographic printing, and nonwovens. With three major production centers in the United States, the United Kingdom, and Italy, and with more than 1,000 team members worldwide, PCMC sells and services its machines installed at customers’ manufacturing facilities across the globe.

PCMC was using Phoenix Contact managed Ethernet switches and a wireless WLAN basic radio, but its existing remote connectivity solution was a proprietary system that had limited functionality. Previously, PCMC sold each customer a PC that had all the software required to diagnose and maintain the machinery, and PCMC would remotely access that PC when needed. This was an expensive solution as it required the purchase and installation of a PC and associated remote access software.

PCMC needed a lower cost, more reliable, and more secure solution, so it could provide better remote maintenance and troubleshooting of operating machines for customers.

PCMC chose to install a Phoenix Contact mGuard RS2000 security appliance on each machine, and an mGuard RS4000 system at PCMC’s office in Green Bay, Wisconsin. The mGuard system in Green Bay accesses any remote mGuard router via a secure VPN connection.

This hardware-based solution provides a number of advantages over the prior software-based PC platform (Table 1). Loading software onto a general-purpose platform like an office-grade PC creates a software-based remote access solution that works well in many applications, but typically not as well as a specially designed and industrially rated hardware-based remote access solution like the mGuard.

Table 1. Advantages of Hardware-Based Remote Access

- More secure

- Resistant to tampering

- Easier to use

- Less expensive as no PC is required

- Requires no software to be loaded at remote PC

- Doesn’t require periodic software updates

- Industrially hardened, unlike an office-grade PC

- Provides consistent remote access methodology

“With more and more devices on Ethernet and the mGuard’s ability to do network address translations, we are able to translate the machine’s network to a PCMC network,” explains Todd Lemke, electrical project engineer at PCMC. “This allows us to sit at our desk and connect to the machine as if we were sitting at the machine connected to its network.”

It also eliminated the possibility of the remote PC’s not functioning properly or being unlocatable. “We are able to save the additional cost of the previous remote PC and software,” adds Lemke.

In some cases, using a PC for remote access can be quite expensive as it may need to be industrially hardened. PCMC used a standard desktop PC to keep costs down, but office PCs can be susceptible to the electrical noise often found in a manufacturing environment, as well as to other harsh operating conditions typical of a factory floor.

A laptop can be used instead, but it’s then necessary to keep track of the laptop. Because a PC or laptop can perform many other functions, it often becomes compromised in terms of security with the addition of various software programs.

PCMC typically placed its PC in a cabinet without a monitor, keyboard, or mouse, so the customer couldn’t compromise it. Still, when remote access was needed, the PC or laptop had to be set up before it could be used.

The hardware-based mGuard remote access solution addressed all of these issues, as PCMC engineers can now access any machine from any place in the world from their desks at work without any additional login or configuration steps or without asking the customer to set up the PC so they can get online.

“Any person that is on the PCMC network has the ability to access any machine as long as they know the IP address assigned to that customer within the mGuard system,” says Lemke. “An engineer can also be sitting in the airport or any other remote location with an Internet connection, VPN into the PCMC network, and use mGuard to access a machine anywhere in the world.”

The mGuard router provides the secure connection that PCMC needs by encrypting the network traffic and password, protecting all data that passes through the device. This way, any information passing over the remote connection is protected as it transmits from one point to another.

The FL WLAN 5101, the newest version of Phoenix Contact’s wireless Ethernet radios, is installed on Fusion press machines and is used as a wireless access point, providing a connection for a customer’s industrial handheld tablet device. An operator can use this tablet or laptop to control the machine from any nearby location. “We are using a hand held Windows mobile device that has an HMI on it that was created by PCMC,” explains Lemke. “It’s used as an HMI to control the machine.”

The mGuard operates on the same network as the radio and gives PCMC engineers remote access to all Ethernet-capable devices on the machine, which typically includes all of the key components of the automation system including the HMI and the controller.

Control

The printing machinery industry, like many others, is rapidly moving to remote access for advantages such as remote diagnostics and software downloads. PCMC was one of the pioneers of remote access in printing machinery, but, as its competitors were catching up, it needed a better system — something that would be superior to all the other PC-based remote access systems used by its competitors.

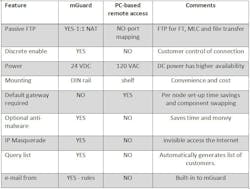

Lemke admits that they had almost the same functional capabilities with the old PC-based system as they do with mGuard. “One thing the new system allows us to do that the old system did not is load firmware to certain devices from a remote location without an additional PC on the machine,” says Lemke. “This is due to allowing passive ftp to the devices.” But the mGuard system provides many more advantages over PC-based remote access (Table 2).

Remote access

“We frequently can solve customers’ issues immediately, especially if it is a new customer with a piece of equipment that they may not yet be completely familiar with,” says Lemke. “It is not uncommon to get a call from the customer stating a problem, and by simply using the mGuard to access the machine’s operator station, we can look at the message screen, evaluate the situation, and point them in the right direction to get the machine back into production.”

PCMC can also go online with the machine’s PLC or other Ethernet-based controller and make modifications to the controller program that the customer may be requesting as a special feature different from the base machine design.

“This saves PCMC and our customer’s time and money,” adds Lemke. “We can have them on the phone, add the feature, get them to try it, give us immediate feedback, and modify as required. This process would take days if we did not have remote access, and it would require a person to be at the facility to load the changes into the controller.”

PCMC engineers can also download new firmware, HMI applications, programs, and documentation using the mGuard remote access system.

PCMC is very pleased with mGuard and the wireless radio. “We install mGuard routers on the majority of PCMC machines we currently build,” says Lemke. “We also went back and installed it on some of our legacy equipment.”

Machines with mGuard routers as standard include PCMC’s Fusion and ELS-Max flexographic printing presses for printing, coating, and laminating; Clipper Flat Pack and Marlin Cross fold wet wipe machines for non-wovens; and Forte and Centrum Rewinders for tissue converting. “All of these machines currently use mGuard routers for remote connectivity for diagnostics and maintenance,” notes Lemke.

“Having a remote connectivity solution that meets both our and our customers’ security needs has greatly increased our support capabilities, and the machine availability for our customers,” says Lemke. “Machine lines are seamlessly accessible when support is required, which means we can access a pool of our technicians and engineers, each of whom can very quickly dive in and assist in troubleshooting without having to travel.”

Modern automation systems need this kind of response. “As integrated diagnostic tools in the automation systems continue to advance, the ability to remotely access machines will grow in importance to meet the demands of our customers.”