Monitoring automation made more affordable

All process plants have control, reliability and energy-use improvement objectives that must be met to remain competitive and keep pace with industry best practices. Health, safety, security, and environmental (HSSE) compliance objectives also must be addressed. Meeting these objectives will often require some level of instrumentation as part of the design, and conventionally this instrumentation tends to be connected back to the automation system with hard wiring or via a fieldbus protocol. But both of these technologies have significant design, cost, and installation implications.

When capital is constrained, budget reprioritization can sometimes result in improvement projects taking a lower priority. When managers see the cost of a wired instrumentation solution, they may postpone implementing it. When wired instrumentation projects do get executed, they tend to be done on a stand-alone basis, offering no opportunity to generate incremental benefits for other projects. The challenge for plant engineers is to develop a common instrumentation framework enabling support for multiple projects, thereby reducing or spreading the cost burden across multiple project budgets.

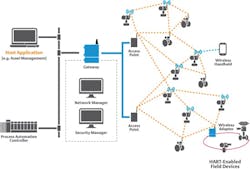

By consolidating budgets and using funds to install wireless instrumentation (Figure 1) and its accompanying infrastructure, plants can not only meet current objectives but also put in place an infrastructure for future improvements. A wireless sensing infrastructure enabled by a common standard such as WirelessHART can create a framework to support multiple continuous improvement initiatives, with these improvements capable of being implemented very quickly at low cost.

Figure 1. Wireless transmitters can be installed anywhere at minimal cost. Once installed with a supporting infrastructure, additional wireless devices can be added easily.

Wireless sensing infrastructure can be used as an alternative or as a complement to wired instrumentation to reduce cost, efficiently manage projects, and reduce the risk of cost escalation. Here's how.

Corn milling plant reverses steam trap losses

At a corn milling plant, Emerson Process Management performed an analysis of the steam-trap system to help the plant identify its high value steam traps, their impact on the bottom line, and the financial impact of a real-time monitoring and maintenance program.

Emerson looked at the plant information concerning the facility’s top 100 steam traps out of 400-plus total traps. The plant was experiencing a 15% annual steam trap failure rate, so the financial impact of the high value traps versus the general population of steam traps was calculated. In this case, the top 12.5% of the plant’s steam traps were responsible for 38% of the steam loss. Correcting this issue through the installation of wireless steam-trap instruments resulted in an annual savings of more than $300,000.

In addition to the savings and payback from such an installation, the fact that a wireless communication system infrastructure now exists will allow for faster future wireless instrument installations at minimal costs.

Organizing for success

The first step is to perform an operational assessment of the plant. Through this assessment, you'll get a better handle on the status of current automation investments and potential problem areas pertaining to reliability, energy, or safety.

The second step is to define an automation roadmap for the site. Implicit within this definition is how technologies such as wireless can achieve a measurable difference in the problem areas defined within the assessment.

Technologies such as WirelessHART are internationally recognized standards that build upon existing HART technology, which is already in common use in process plants. This means the WirelessHART standard is readily accepted and easily integrated into most any automation system, irrespective of the system's age. The user is thus not constrained by the limitations of the site’s existing automation and instrumentation systems.

The monitoring of heat exchangers offers one example of where wireless can be used to quickly implement improvements at low cost with little or no interruption to existing operations.

Heat exchanger monitoring

Heat exchangers can be a major source of downtime, resulting in considerable maintenance expense, significant loss of production, and poor plant performance. A plant's existing monitoring approach may involve manual spot measurements performed on a periodic basis. These types of measurements provide an inconsistent view of failures and are time-consuming, with the accuracy of assessments dependent upon technician expertise.

Automating the collection of heat exchanger operating status using a conventional approach of installing and wiring new instruments to an existing automation system is often prohibitively costly. Tying in new wired signals to an existing system will involve locating spare input cards, marshalling panel space and field junction boxes (Figure 2). Often, required space and system capacity won’t be available, or at best it will be severely limited. This is one of those projects where the cost means the priority is relegated in favor of a more pressing or urgent task or one that costs less.

Figure 2. Adding wired instrumentation to a heat exchanger is easy, provided that the original engineers allowed for spare wires, input cards, field junction boxes, and other wiring and connections back to the control system.

Of course, measuring and improving process plant performance with instrumentation has been going on for decades with wired instruments, so how is doing the same thing with wireless different and better?

Using WirelessHART technology, heat exchanger monitoring (Figure 3) can be quickly automated and integrated with the existing automation system in a matter of days. Minimal fieldwork is required – just the installation of a wireless acoustic transmitter at each steam trap deemed critical and a WirelessHART gateway. One gateway can communicate with hundreds of distributed wireless devices, and the gateway then connects to a base station located near the automation system. This allows data to be quickly collected for continuous online analysis.

Figure 3. Adding wireless instrumentation to a heat exchanger requires no supporting wires or infrastructure, so the installation can be done in a matter of days.

In a budget-constrained environment, projects such as wireless steam-trap monitoring enabled using wireless sensors will have a low capital investment and quick payback, require less scrutiny, and can often be funded through operating rather than capital budgets. A comparable wired installation would take months just for engineering and installation. By contrast, wireless installations are often fully implemented, paid for, and returning on the investment before a comparable wired solution is even installed

OpEx and HSSE together

Operational expense (OpEx) targets are multifaceted. For example, a directive might be to cut energy use by two percent and increase plant uptime by one percent. Meeting quality objectives, such as improving product purity or cutting rework, often require investments to improve process control. And of course, every plant has HSSE targets mandated by corporate and various regulatory agencies.

A wireless infrastructure is scalable and flexible, so once it's in place, other OpEx or HSSE projects can leverage the initial investment of the wireless network by layering other applications which can all coexist in the same network. For example, a program to improve compliance to regulatory directives in the monitoring of safety showers can use the same wireless network infrastructure as a heat exchanger monitoring system.

Modernization projects requiring conventional instrumentation upgrades can also significantly benefit. For example, even substituting a few wireless signals on a mostly wired project can deliver significant benefits for the project and into the future. Present benefits are gained when wireless is used to provide access to instruments located in areas which are difficult and expensive to access with wires. Future benefits are realized by virtue of the fact that once deployed, the wireless infrastructure is there for future projects.

Wireless advantages

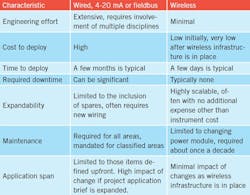

Compared with wired installations, wireless instrument installations are inexpensive, quick and simple (Table 1).Therefore, wireless infrastructure and instrumentation is often ideal for quickly reducing operating expenses at minimal cost.

Table 1. Wired versus Wireless

The first hurdle to kicking off a conventional wired project on an existing brownfield site is the sheer complexity of getting all stakeholders aligned and signed up for the required engineering effort. This will typically require multidiscipline efforts involving the automation, electrical, instrumentation, operations and maintenance departments. Being able to secure the time and commitment of personnel can be difficult.

Conversely, a wireless project requires minimal support from each department, so interdisciplinary coordination is greatly simplified, and project critical path planning is less onerous. For example, instrument commissioning is not reliant on a whole range of other things being in place such as marshalling panels, junction boxes, conduit, I/O cards, etc. The simplified wireless implementation means the cost and time to deploy is minimal, with installations taking days rather than weeks.

Once in operation, the wireless network (Figure 4) can accommodate multiple applications, unlike a wired project which is typically designed to solve the problem at hand. Ongoing reliability and maintenance is also greatly reduced as wired instrument installations require periodic inspections as defined in IEC60079 Part 17, while wireless installations do not.

Figure 4. Once a wireless network is in place, additional instruments can be added to the network, thus reducing the cost for future improvement projects.

Guidelines for employing wireless

Many process plants have realized benefits by installing wireless instruments and infrastructure for applications such as monitoring heat exchangers, pressure relief valves at flare gas stacks, pumping systems, and steam traps (see sidebar). In many cases, wireless instrumentation can be installed where wired instruments would be too difficult or expensive to install. Here are some guidelines for employing wireless:

People: Set up a cross-functional working group to align the organization, define current problem areas and set a road map for functional requirements. Look at manual processes where repeatability and consistency are required for uniform operations, and determine how these can be automated.

Moazzam Shamsi, MSc, BEng, CEng, MinstMC, is a global solutions architect with Emerson Process Management. He has been an automation professional for 25 years, and his career spans a broad range of industries in roles from technical leader to project manager. He presently works for Emerson Process Management, where he directs Emerson’s global wireless consulting and execution solutions on large capital projects.

Involve maintenance personnel to identify pieces of equipment (steam traps, for example) that cause problems. In many cases, plants rely on manual rounds because conventional instrumentation has been far too expensive to justify considering automating monitoring. With wireless, almost any piece of equipment anywhere in the plant can be monitored for a reasonable cost.

Implementation process: Put into practice a system of continuous plantwide improvements, where manual tasks or lack of information can be addressed through the addition of measurement points. Once a wireless infrastructure is in place, additional projects become easier and less expensive.

Technology: Adopt HART-based technology plantwide. This technology is readily accepted in most every plant because the tools and device interactions for WirelessHART devices are the same as for wired 4-20mA HART devices. This lets plants focus on the information rather than the technology transport mechanism.

The operational assessment described above can help plants prioritize and justify project budgets previously deemed low-priority or unattainable with conventional wired instrumentation. The assessment also can show how to consolidate projects that enable incremental improvements across multiple areas. Finally, an operational assessment can illustrate how to extend the life of an aging automation system by wirelessly enabling that platform, allowing for an expansion of signals and enhancing the capability to receive additional actionable information through wireless signals.