How to better manage your CMMS from implementation to end of life

When you ask management for their perspective on where the CMMS/EAM industry is headed, most will respond with a fairly technical mindset, quoting the latest buzzwords such as Industry 4.0, Digital Transformation, Smart Factory, Industrial Internet of Things (IIoT), Artificial Intelligence, Big Data, Cloud Computing, and the like. Although connecting increasingly smarter assets together in real-time for the purpose of more effective monitoring and control is undoubtedly a worthy goal, it is not the only key trend in the industry. Equally important is the trend to integrate and support best-practice processes with functionality relevant to the entire asset lifecycle.

This article looks through the lens of best practices, from EAM strategy to the disposition of assets, and how the more sophisticated CMMS/EAM system solutions are enabling companies to standardize and streamline processes. By all means, look for a package that delivers on your company’s vision for Industry 4.0. However, the real power of the CMMS/EAM system is its ability to configure a technical solution, supporting efficient and effective processes and organizational structure.

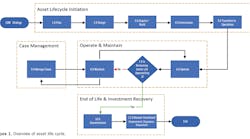

Figure 1 provides an overview of the asset lifecycle. There are four phases of the lifecycle identified, namely:

- Asset Lifecycle Initiation

- Operate and Maintain

- Case Management

- End of Life and Investment Recovery

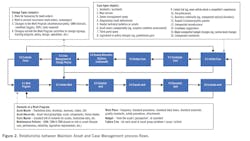

In my experience, roughly 60 to 80% of the total cost of ownership (TCO) for industrial assets lies in the Operate and Maintain phase. This may explain why CMMS/EAM system functionality has focused on this phase over the decades. In more recent years, CMMS/EAM vendors and their customers have realized the potential of increased functionality supporting Case Management. Work orders deal with expected work, whether triggered by asset failure, use (e.g., time, meter, or event), or asset condition. Cases deal with the world of the unexpected, such as COVID-19 or premature degradation. Figure 2 provides an overview of the intimate relationship between the Maintain Asset and Case Management process flows.

Another area of expansion for CMMS/EAM system functionality are the remaining two phases, i.e., Asset Lifecycle Initiation and End of Life. Enterprise Resource Planning (ERP) vendors with Enterprise Asset Management (EAM) functionality may have a head start for supporting these two phases because they typically have more robust and fully integrated accounting and procurement modules.

Throughout each phase of the asset lifecycle, there are potential process improvements available through proper configuration and the use of CMMS/EAM features and functions. Best practices and supporting CMMS/EAM functionality are described below for each numbered box shown in Figures 1 and 2. Many companies have realized after multiple CMMS/EAM system implementations that process transformation is no easy task. Probably the largest roadblock is the behavior change of all stakeholders, regardless of how rich the CMMS/EAM system functionality. Removing these impediments is critical in moving the organization closer to best practices and getting the most out of your CMMS/EAM system.

Asset lifecycle initiation

Although assets vary widely in terms of form, fit, function, and cost, it is surprising how they go through similar steps throughout their lifecycle. Driven by an enterprise asset management strategy that is revisited at least once per year, plans are drafted to create, procure, or modify assets for operations based on design specifications. Best practices and supporting CMMS/EAM system features are discussed below for this phase of the asset lifecycle.

1.0 Plan – There are typically three levels of planning. The expected output of the highest level of planning is the long-term capital plan with a planning horizon of typically 25+ years. The CMMS/EAM system packages have historically been reluctant to get into this space, even though the information collected in the long-term capital plan is very much relevant to the asset manager. For example, based on building condition assessments conducted every few years, capital requirements for existing structures can be identified and a portfolio analysis done, complete with facility condition index and long-term budgets. The good news is that some of the leading packages can be configured to provide these reports for existing or new assets, if the information is entered.

The next level is short-term planning, which is typically aligned with your company’s annual budget cycle for both capital and operating dollars. The annual plan is ultimately divided into monthly buckets for transfer to those responsible for scheduling. Here, too, the CMMS/EAM systems fall short in terms of extensive support functionality for the annual plan, especially for planning capital growth (versus maintenance), although configuration on some packages is possible.

The lowest level of planning is at the project level. Many of the CMMS/EAM packages have excellent two-way integration capability with leading project management software packages like MS Project or Primavera. But the project management capability built into the CMMS/EAM software for some vendors is outstanding for planning new capital projects or shutdowns, turnarounds, and outages. Look for packages that move project plans seamlessly into the scheduling module of the CMMS/EAM system and vice versa.

2.0 Design – The CMMS/EAM system is not a design tool like AutoCAD or MicroStation. However, the output of the design stage (i.e., drawings) can be linked to asset master records. A few CMMS/EAM systems have built-in document management capability, but most can at least hyperlink to external document management systems, the cloud, or LAN.

3.0 Acquire/Build – Although many CMMS/EAM systems have fairly robust invoicing modules, the focus is typically on the purchasing of spare parts for current assets, as opposed to new and complete assets such as plant equipment, vehicles, etc. In contrast, ERP systems that have fully integrated EAM modules have greater functionality for acquiring new assets, including supply chain management and fixed asset accounting modules.

Similarly, most CMMS/EAM systems lack the functionality for managing the construction or fabrication of assets. One exception is the job estimating capability found in a few packages. This functionality includes a configurator for building compatible units from parts/equipment/labor, and the assemblies from the compatible units; costing of the compatible units and the assemblies through integration with the work order system and inventory control modules; the accommodation of cost variations, such as intended function of the unit or degree of difficulty in doing the work; reconciliation of costs, comparing “as planned” vs. “as built” parts usage; and integration with regulatory accounting.

4.0 Commission – Although many CMMS/EAM systems provide a status field on the asset master, which can be set to “commissioning” for a new or reconditioned asset, most packages do not provide commissioning assessment templates, deficiency ranking by severity, and other commissioning tools. However, most packages allow hyperlinks to supporting documentation within the asset master.

5.0 Transition to Operations – There are two areas that hold tremendous potential for improvement: (1) greater consultation with operations and maintenance throughout the entire asset lifecycle initiation phase; and (2) greater timeliness and accuracy of data transferred to Asset Managers regarding new assets. These are primarily management and process issues, so very few CMMS/EAM packages have significant functionality to help exploit this huge opportunity.

Operate and maintain

Once an asset has been successfully transitioned to operate and maintain, its status is changed to “in service” on the asset master and depreciation begins. The vast majority of the asset lifecycle in terms of time and dollars is spent in this phase as described below.

6.0 Operate – It is important for the CMMS/EAM to be able to distinguish between (a) downtime, whereby an asset is available but not in use by operations; and (b) downtime, due to machine breakdown. Some CMMS/EAM packages allow manual entry or correction of the automated feeds of downtime alarms from process monitoring and control equipment. An ERP system with EAM functionality can more easily track this distinction automatically, especially manufacturing operations through integration with their production planning and control modules.

7.0 Remaining Useful Life (RUL) – Throughout its lifecycle, asset managers must be vigilant in determining end of life for a given asset. The CMMS/EAM software can help with certain calculations, such as cost of repair versus replacement; however, there may be other reasons for replacement including technical obsolescence and changing corporate needs.

8.0 Maintain Assets – The maintain assets process flow can be divided into six major steps as outlined in Figure 2, and described below in terms of best practices and underlying CMMS/EAM system features.

8.1 Work Program – The critical foundation of any CMMS/EAM system is the work program. The box at the bottom of Figure 2 outlines the standard elements of a work program. The more sophisticated CMMS/EAM systems provide a wealth of features, such as seamless integration with Geographic Information System (GIS) software and the asset master. The integration allows the mapping of asset locations as a point, line, or polygon, and extensive sort / filter capability using either the map or asset master.

Other key features include:

- Extensive functionality for defining maintenance policies, i.e., failure-based maintenance (FBM) or run to fail, use-based maintenance (UBM) for periodic routine maintenance, and condition-based maintenance (CBM) for inspections that may automatically generate work if readings entered exceed user-defined upper or lower control limits.

- Nested and hierarchical problem, cause, and action codes (i.e., failure tree), complete with troubleshooting and predictive database based on Pareto analysis of historical data.

- Full budget extension capability based on annual/monthly plans covering work anticipated for each maintenance policy (including FBM), which in turn is composed of SOPs within the work plan that provide standard labor hours × labor rates, standard parts × standard cost for each SOP or external charges.

8.2 Initiate Work – Advanced CMMS/EAM systems forecast UBM and CBM inspections, while FBM work requests are sourced from operator/customer dispatch or help desk, follow-on work, and integration with automated failure alarming systems. A key differentiator amongst the packages is the level of sophistication regarding asset condition triggers, including:

- multiple condition indicators per asset;

- a trigger from one of these indicators resets all other triggers for a given asset;

- combining indicators using Boolean logic to create consolidated or alternate indicators;

- triggering an action on a preferred day or date if meter reading is within tolerance;

- forecasting when the next meter reading should occur based on historical readings;

- validating readings with a user-defined validation formula;

- graphic showing component hierarchy and corresponding indicators;

- conditions and alarms visibly distinguished on the graphic;

- trigger based on calculation of the history of asset condition readings (e.g., average, average variance, sum, median, max, or min of last 10 readings must be within certain control limits).

8.3 Schedule Work – CMMS/EAM packages vary in their abilities to support the Scheduling role, including scheduling UBM work by the following:

- the hour;

- the number of recurrences (i.e., repeat 10 times and then stop);

- recurring month(s), week(s), or day(s) of the week, starting on a specific date;

- specific calendar dates (that are not recurring);

- specific calendar dates as exceptions (not recurring);

- specific calendar dates as exceptions (recurring);

- multiple start/end dates for seasonal or blackout periods.

Another impressive differentiator regarding scheduling functionality is exhibited by the sophistication of graphical scheduling tools, such as drag and drop capability for backlogged work orders, simulation mode that allows users to play with various scenarios and then lock in the one that works best, and two-way integration with popular project management software packages like Primavera and MS Project.

8.4 Execute Work – Maintainers certainly appreciate a simple, easy-to-use mobile application with access to rich functionality as needed, including drawings, maps, troubleshooting database, warranty information, parts bill of materials, and a complete asset history. The mobile version should have store and forward capabilities to deal with unwanted dead spots in cell coverage. Another handy mobile feature is a “running clock,” whereby the CMMS/EAM software keeps track of labor hours per work order or activity codes entered (e.g., travel time).

8.5 Document Work – CMMS/EAM software on mobile devices should also facilitate data entry. For example, signatures can be captured on forms, pictures can be uploaded, maps can be marked showing the actual work location on a map (i.e., a point, line, or polygon), maps can be redlined to show anomalies, such as an unexpected encumbrance or an asset in the wrong location, and warranty claims applicable to a given asset can be completed.

8.6 Evaluate Work – What CMMS/EAM systems do with data entered by maintainers is essential in getting the most out of your software. Reports and dashboards that are easily configured directly by the user is an extremely valuable feature. Standard reports should include:

- the plan vs. schedule vs. actual for labour hours / cost;

- the “bad actors” report, displaying a Pareto diagram of the assets causing the greatest expenditure of maintenance hours or dollars;

- the root cause analysis report for diagnosing recurring problems;

- the work backlog report, showing a dynamically changing prioritization of pending work orders.

Some systems have very sophisticated reliability engineering tools, such as RCM and Weibull analysis capability.

Case management

Surprisingly, only a handful of CMMS/EAM systems can properly handle cases with the same level of sophistication as that of work orders. Cases are a massive area of potential improvement for asset managers, as they deal efficiently and effectively with minimizing the disruptive nature and high cost of the unexpected. As well, once cases are resolved and closed, the work program is updated for additional improvements to expected workflows.

9.0 Manage Cases – The case management flow as depicted in Figure 2 is complementary to the Maintain Assets process flow. Steps are as follows:

9.1 Initiate Case – The box shown in Figure 2 entitled “Case types (inputs)” provides a sample list of the many possible types of cases, depending on your industry. Typically, companies have a wide range of separate systems or informal means of tracking each of these case types. For example, many large companies have an incident management system usually controlled by HR and focused on the human aspect of an accident or near miss.

However, an incident more often than not involves an asset of some kind requiring immediate remediation (e.g., shut down a line, patch a gas leak), and eventually a more permanent solution (e.g., replacing the asset). When a case is opened within the CMMS/EAM system, any relevant work orders or activities can be charged or linked to the case. A case owner (typically the asset steward for the appropriate asset class) is assigned to manage the case until closure. More sophisticated systems allow user-defined changes to workflow depending on the case type selected (i.e., different case types require different data to be collected).

9.2 Investigate Case – Once a case is opened, the next step is to launch an investigation, which may take anywhere from one day to several years. During that time, various stakeholders will be consulted, tests conducted, pictures taken, and so on. More advanced CMMS/EAM systems will be able to log these activities, write notes, set appointments, attach documents, and interface with popular communication and calendaring software.

9.3 Analyze Case – At some point in the life of a case, data collected must be analyzed. In turn, this may lead to further investigation and back again for more analysis. More sophisticated CMMS/EAM systems have numerous tools for analysis, including correlation analysis, root cause analysis, Weibull analysis or risk analysis.

9.4 Develop Alternative Solutions – Based on the case investigation and analysis steps, alternative solutions are documented within the CMMS/EAM system as to how to:

- deal with the case (e.g., customer suggestion, regulatory change, COVID);

- avoid a worse situation (e.g., near miss, technical bulletin, latent risk);

- prevent recurrence (e.g., unexpected vandalism, incidents).

Cost/benefit and risk analysis on each alternative is documented as well.

9.5 Enter Management of Change Process (MoC) – Although not every case will require it, a formal MoC process should be established with cross-functional management to assess and select the most appropriate solution. There are numerous considerations as shown in the box entitled “Change types (output)” within Figure 2. Advanced CMMS/EAM systems will be able to document case solutions, allow any necessary changes to the work program, and integrate whatever projects, campaigns, or work orders are launched as a result.

9.6 Evaluate Cases – As in the evaluation of maintenance work orders, the better CMMS/EAM systems will provide extensive dashboards and reporting capability to ensure that cases can be tracked (e.g., case status, case costs, average time to case closure for a given case type). The goal is to reduce the number of cases over time, the cost of managing them, and the overall case impact. Surprises cannot be eliminated, but the unexpected can certainly be minimized and dealt with efficiently and effectively.

End of life and investment recovery

As displayed in Figure 1, once RUL is deemed approaching zero, the asset(s) is ready for entering the End of Life and Investment Recovery phase described below.

10.0 Decommission – The first step in this phase is to determine the disposition option that will provide the greatest investment recovery. Alternatives to consider are upgrading and/or repurposing the asset, salvage, sell, lease, transfer, split, hold, and other possibilities. The EAM/CMMS system may help with the cost/benefit analysis. Depending on the value and complexity of the asset, a decommissioning template may be necessary to assess the asset and address any deficiencies for which there is net benefit. Using the CMMS/EAM system, any decommissioning maintenance costs incurred can be charged appropriately.

11.0 Recover Investment – The last step in the overall asset lifecycle is the actual disposition of an asset, as well as allocation of any revenue/costs to the appropriate charge codes. The CMMS/EAM system should then be updated as to asset status and disposition, for a complete and accurate equipment history and costing.