How asset management software enables better asset criticality analysis

Recent events brought on by COVID-19 exemplify how asset criticality analysis is beneficial for manufacturers, but it is not a one-and-done proposition. Federal orders under the Defense Production Act compelled some manufacturers to immediately begin producing items that were in short supply. This caused a sudden shift in their priorities, and elevated the criticality of assets and systems that comprise their accelerated, reconfigured, or repurposed production lines.

It is a reminder that operational priorities will evolve, environmental conditions will change, and assets will be upgraded or replaced, sometimes on a moment’s notice. In fact, a stale criticality analysis can become a liability. It is imperative that you understand which systems, equipment, and components are mission-critical, both to identify and avoid unacceptable risks before a crisis hits, and also to rapidly recover, should it unfold.

With a current asset criticality analysis, asset owners, operators, and reliability and maintenance service providers are able to make effective, priority-based decisions, and to take steps to establish continuity or contingency plans where they are needed most. Asset management software plays a crucial role in ensuring the analysis is effective and the source data is current.

Known advantages of criticality analysis

Heightened attention is imperative for assets with the highest probability and consequences of failure. These are the assets prone to unacceptable direct costs and collateral damage such as injuries or fatalities, environmental damage, widespread equipment and facility damage, product quality degradation, production loss, scrap and rework, and/or reputation concerns.

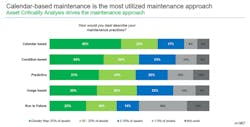

Asset criticality analysis provides the requisite awareness and is a recognized best practice that helps to shape Reliability Centered Maintenance (RCM) decisions. The 2019 Asset Performance Management (APM) Benchmarking Study from ARC Advisory Group found that “for many respondents, the asset-criticality analysis process drives the maintenance strategy and approach.”

The researchers asked leaders across multiple industries about their maintenance practices. The bars in Figure 1 represent the percentage of assets included in the respective maintenance approach.

Peter Reynolds, contributing analyst at ARC Advisory Group, explains that successful RCM programs help companies decide which maintenance approach works the best. “For example, run to failure might be perfectly acceptable for a chiller that runs periodically and is not critical to production,” he explains.

For assets of mid-level criticality, Condition-Based Maintenance (CBM) and Preventive Maintenance (PM) – generally calendar- or usage-based – are established and relatively affordable strategies that are widely used. Higher-risk and mission-critical assets and systems are prime candidates for Predictive Maintenance (PdM) or Prescriptive Maintenance (RxM), which is PdM with recommended solutions. Advanced analytics with machine learning (ML), smart sensors with cloud connectivity for streaming condition monitoring data, and digital twins for modeling and simulations are available technology options.

Besides establishing the appropriate maintenance strategies, criticality awareness helps planners and schedulers to prioritize work order tasks and scheduling; allows prioritization of inventory management, parts procurement, and capital budgeting for highly critical assets; and reveals where contingency plans, alert rules, and escalation processes are most needed.

Criticality can also be applied at the failure cause level through Failure Modes, Effects, and Criticality Analysis (FMECA). FMECA proactively identifies potential modes of failure, their effects (consequences) and criticality (risk severity and probability), and then prioritizes suitable corrective actions. FMECA’s reactive counterpart, Root Cause Analysis (RCA), feeds into updated asset criticality analyses.

Why the software matters

Asset management software (EAM/CMMS) augments criticality analysis for machine sets and enables utilization of that information, helping companies to systematically lower their operating costs and improve reliability, says Tim Dortch, founding principal of Reliability Solutions (www.reliabilitysolutions.net).

“When it comes to criticality analysis, people have to remember that the software isn’t going to do it for you. There are methodologies you will have to use to find out where and why you are having breaks,” adds Dortch. “We use Asset Strategy Development (ASD), which is an RCM analysis hybrid. It drives you to the criticality of a piece of equipment and the things that you’d better do right to maintain the equipment correctly.”

All of that information goes into the software. “A good EAM/CMMS will help you benchmark your critical equipment repairs over time and understand what you are really spending in a time-based manner. But I’ve seen a lot of underutilized data floating out there,” observes Dortch. “If a mechanic is in the field, the pertinent information should be complete, easily accessible, understandable, and relevant to repairing the equipment.”

To get to that level, everybody needs to fully understand the system and what you are trying to accomplish, cautions Dortch. “A lot of people fail in the implementation of EAM/CMMS because they don’t train the correct people. It’s not just a management system; it’s a way of doing business for maintenance and even production,” he explains.

Reliability Solutions also teaches that any software is only as good as the data that is put into it. Lack of a good system to capture performance, failure, and maintenance data from the field technicians seriously compromises the software's capabilities. This is a part of EAM/CMMS software implementation that is often overlooked.

Extended application

Traditionally, a single criticality value is associated with a piece of equipment or system. IFS enables the definition of criticality matrices for four risk elements, including:

- Personnel injury

- Environmental spills

- Equipment/material damage

- Production losses

The software company reasons that one asset may have single or multiple risk elements, and users need visibility into the severity and probability of each risk element associated with a critical asset.

IFS also encourages propagating FMECA results and the corresponding maintenance plans across multiple equipment tags, rather than requiring a separate RCM analysis for each equipment tag, because it is more efficient to group them based on similar equipment characteristics, functional performance requirements, and the operating context.

COVID-19’s not-so-gentle reminder of the dynamic nature of asset criticality should inspire a fresh look at everyone’s current criticality designations. If yours have gone stale, now is the time to get them updated.