Too big to succeed: How to rightsize your compressed air system and start achieving real cost savings

It is rare for compressed air consumption to be consistent, so it makes sense for air systems to be sized so that the total capacity meets peak demand. The problem is that most systems have far more capacity than needed.

Kaeser Compressors has performed more than 10,000 air system audits in the United States, and we have found that, on average, users operate at only 44% of total capacity. Despite a concerted effort by compressed air professionals to educate users about the negative impacts of oversizing on operations and the bottom line, gross oversizing remains common practice.

How does this happen? In many cases, users select compressors based on the compressor(s) that they already have, adjusted with some prognostication about expected business growth. Generally, little measurement and analysis goes into it. Also, most operators are inclined to up-size for peace of mind. They don’t want to hear complaints of equipment with low pressure alarms, nor do they want to re-revisit compressed air system design every few years as they grow. So, they purchase as big as their budget allows at the outset.

Overly conservative consulting engineers may add to the problem by assuming that all pneumatic equipment will operate fully loaded all the time. They may even add a safety factor on top of that. In nearly all cases, there’s fudge factor on top of fudge factor, with all stakeholders believing that they are acting in the interest of ensuring compressed air availability, without understanding the negative impacts on energy consumption, maintenance costs and long-term reliability.

Impact of oversizing on energy use

Compressed air efficiency is best measured in terms of specific power, which is most often expressed in kW/100cfm. Specific power increases as compressors operate further away from their full output capacity. To be clear, higher specific power means higher power consumption and lower efficiency. In fact, a specific power measurement of 25kW/100cfm is a good target; 20kW/100cfm is considered excellent.

The Compressed Air and Gas Institute (CAGI) has an excellent program that encourages compressor makers to publish the specific power for each compressor. This tool is a great way to compare two compressors side by side, but it cannot be used to predict what the user’s actual system performance will be. As the car makers say: “your mileage may vary.” So much depends on how the compressors are run. The CAGI data sheets for fixed speed machines assume 100% load, which rarely happens in practice. Whether a single machine or multi-compressor system, under-utilized compressors do not operate at their datasheet performance specification.

From our many system studies, we know that systems are grossly oversized. Let’s look at some actual examples of oversized systems and the inefficiencies that resulted.

- Example A. For this greenfield plant, the company specified dual 125 hp compressors, two 230 cfm refrigerated dryers, 1,000 gallons of storage, an air main charging valve, and a master system controller. The system was grossly oversized and their specific power was over 66kW/100cfm (more than three times as large as the 20 kW/100cfm target). Their needs could be met with a pair of 15 hp units.

- Example B. The facility currently operates with a 50 hp screw compressor, a 285 cfm refrigerated dryer, and a 400 gallon receiver tank. The peak demand measured was 65 cfm and the average flow was 22 cfm, so the 236 cfm compressor was far over-sized for the current demand. The calculated system specific power was also sky high, at just under 66kW/100cfm. The company would be much better off with a pair of 10 hp compressors.

- Example C. This facility currently operates with three 200 hp compressors, three 1,000 cfm refrigerated dryers, and 3,800 gallons of dry storage. This system is highly variable in demand (891 to 2,417 cfm) and was aptly designed with multiple units to supply this full range efficiently. The specific performance was very respectable at just under 18kW/100cfm.

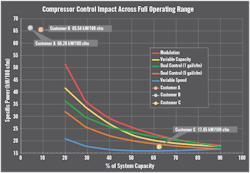

Figure 1. Efficiency curves for common compressor control types.

Figure 1 plots efficiency curves for common compressor control types. This chart shows how the efficiency of compressors declines dramatically as demand decreases as a percentage of capacity. We’ve added data points showing where a few actual customers operate on this curve. As you can see, some are off-the-charts inefficient, but achieving efficient operation is certainly possible.

A key lesson is that the further compressors operate from full load, the lower the yield on this costly input in terms of cost per cfm. Regardless of control type used, a poorly sized system will perform poorly. You can spend more for the most efficient compressor in its class, but if it is the wrong size, the money spent to gain efficiency is wasted. This highlights the point that system design has greater impact on efficiency than the efficiencies of the individual machines in the system.

It’s not just about energy

Of course, energy is only one component of your costs to make compressed air. While energy may be the easiest cost to recognize and measure, the wasted energy associated with over-sized systems might be the least significant component of compressed air cost in your operation.

Over-sizing frequently results in increased cycling, which has several negative effects on compressors. We’ve found that for under-loaded systems, maintenance and repair costs increase as a portion of total operating cost.

Does this sound counter-intuitive? Think of your car. Cost per mile for gas and maintenance goes down if most miles are highway miles. Highway miles are also gentler on your car (fewer starts and stops, etc.). City miles are notoriously inefficient with fuel; they also accelerate wear on the motor, the brakes, steering, and suspension.

Likewise, low-loaded compressors are more likely to show wear at an accelerated rate. Inlet, vent, and other internal valves cycle many more times at low load. Motors start and stop more frequently, affecting bearing and winding life. On direct drive units with polymer couplings, frequent cycling can reduce coupler life. Frequent loading and unloading puts more wear on thrust bearings in the airend.

Further, if the unit doesn’t run enough, the compressor may not reach proper operating temperature, which results in moisture accumulation in the lubricant (in fluid-injected compressors). This is a common cause of premature airend failures. Frequent changes in temperature can also cause metal fatigue on coolers. These conditions call for increased frequency of preventive maintenance and the likelihood of downtime for repairs.

A review of service records showed that units with lower duty cycles had a significantly shorter mean time between failure (MTBF). Because compressors are usually serviced based on total run time rather than actual load time, a machine that idles a lot costs more in parts and labor per loaded (i.e., productive) hour. If you calculate the service costs based on cfm produced rather than hours of run time, you’ll find that PM and repair costs per cfm rise also.

Another downside to poorly sized systems is pressure fluctuation. Swings in pressure may result in defective products, and more sophisticated production machines may have sensors that shut down the equipment if pressure is outside of design specifications.

Depending on the cost of raw materials and value of finished product, the costs of downtime and scrap may far exceed the losses in energy efficiency and service costs. Downtime and scrap caused by pressure fluctuations, high service and repair costs, and high energy costs are problems that many operators simply live with as expected costs of operating compressors. But they don’t have to. The first step is an honest assessment of how well your compressed air system is sized.

Meeting the challenge

If you are planning a compressed air system for a new plant or expansion, you may only be able to estimate your compressed air demands. The smart money is spent splitting the estimated demand among multiple compressors and having good controls (and ample storage). Using variable output (variable speed) compressors as trim machines is part of a good strategy. Even if the system is somewhat oversized, the controls and storage will compensate.

For existing systems, the first step is an accurate air system assessment to determine how well your system is sized and controlled. If your budget allows for replacing compressors, the ROI from lower energy consumption, lower service expenses, and reduced downtime may justify replacing over-sized compressors and adding controls.

If your budget cannot accommodate new compressors, there are lower-cost investments that can help mitigate over-sized compressors. Adding storage often reduces compressor cycling and can stabilize pressure. In some cases, flow controls may further improve the effect of storage. For systems with multiple compressors, adding a modern multi-unit controller will definitely help reduce starts/stops while stabilizing pressure and provide additional benefits such as remote monitoring and energy consumption information.