Vent gas compressors fit in a category of positive displacement machines often used in low-cost petrochemical plants. As a general rule and compared with other available options, sliding vane compressors are selected for vent gas duty by user-purchasers whose emphasis is on low initial cost. If emphasis is placed on maintenance cost savings and long uninterrupted run length, screw compressors or even reciprocating machines are often preferred. Let’s consider here certain principles relating to experience checks and follow-up that carry over into asset selection in general, bearing in mind that reliability principles are universally applicable.

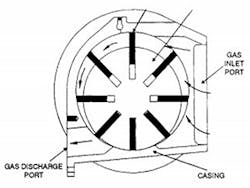

Figure 1. Cutaway view of sliding vane compressor often used in vent gas service. Source: GE Oil & Gas, Houston

Emphasis often differs

Energy conservation is of ever-increasing importance to process plants of all sizes. Gas streams that were flared a decade ago are now often recompressed and recycled back to the suction vessel or sent to furnace heaters and other energy consumers. Depending on flow and compression ratio, a wide range of compressor configurations, both positive displacement and dynamic, could be considered. As a side comment, twin-screw “wet” rotary positive-displacement machines are in strong contention for many of these duties. Moreover, lobe-type machines are known to be suitable for many recompression duties.

This article is part of our monthly Tactics and Practices column. Read more Tactics and Practices.

It should be noted that the economic justification and return-on-investment calculations for such projects are often based on cost-estimating manuals that list the least-expensive compression machinery. Only a thorough life-cycle cost analysis, however, can determine which equipment ultimately will make the most economic sense in the long run. This isn’t to say that the economics never favor less-expensive machines – if future maintenance is not a factor in the decision-making process, certain less-expensive options may well be “in the running.”

In essence, sliding vane compressors are sometimes offered for vapor recompression services. They are rotary-element gas compressors in which spring-loaded sliding vanes are evenly spaced around a cylinder. As this cylinder revolves off-center in a surrounding chamber, the vanes pick up, compress, and discharge the gas being processed. In one of many possible applications, these compressors had somehow been recommended to an overseas reprocessor of used lube oil. The vapor recompression duty included naphtha, gas oil, and a number of other gases. Sliding vane compressors, however, make rubbing contact and will experience more wear than certain compressors with less or no sliding contact. Gas composition and cleanliness also make a difference in the selection process, and sliding vane machines should be assumed to experience lower availability and higher maintenance cost. Because engineers hadn’t taken these facts into account, the compressors proved uneconomical and had to be replaced by more-suitable machines

Experience checks are important

Heinz P. Bloch, P.E., is owner of Process Machinery Consulting in Westminster, CO, and the author of close to 700 articles and 20 books, including “Pump User’s Handbook — Life Extension” and “Practical Lubrication for Industrial Facilities.” Some of his work has been translated into five foreign languages, and Bloch has seven machinery-related patents to his credit. He is an ASME Life Fellow and was one of the original Texas A&M University Pump Symposium advisory board members. Contact him at [email protected].

A thorough experience check and open communications with competent vendors will help the purchaser make a smart selection. Sliding vane compressors from vendor A might be better than sliding vane compressors from vendor B. Service competency could favor one over the other, as could maintainability, accessibility, space occupied (the equipment’s footprint), operating efficiency, downturn (reduced capacity), and overload considerations. However, the sliding vanes of these compressors (see Figure 1) by definition make rubbing contact and will experience more wear than compressors with lower – or zero – sliding contact.

Gas composition and cleanliness also make a difference in the selection process, and the sliding vane machine should be assumed to experience lower availability and higher maintenance cost. This must be weighed in making a buying decision.

Follow-up is needed

In following up with the vendor, the potential buyer should ask for references and then make the effort to check these out, even by making a visit to a present user’s plant site. Consider vane tip velocity, heat generation and dissipation, suitable oil types, oil-to-process compatibility, and even oil consumption and lubricant cost. For higher overall reliability and availability, one might look at twin-screw rotary compressors. Dry-screw and wet-screw machines are used in these services; a thorough life-cycle cost analysis will help determine which might be most appropriate.

Figure 2. Cross-section view of sliding vane pump

The same analysis is needed if certain (typically higher) compression ratios point to reciprocating machines. There is much favorable experience with labyrinth piston reciprocating compressors. These, too, are available in many sizes and will require less maintenance than seemingly equivalent reciprocating compressors with piston rings and rider bands.

Finally, a few words about packaged machines, usually as small as sliding vane machines. “Packaged” implies that the compressor manufacturer or another entity has mounted the compressor and its support system on a skid. These skids facilitate installation, and there are installation cost advantages.

But whenever you buy a “package,” and regardless of its physical or power-indicated size, be sure that the overall turnkey responsibility is clearly defined in the contract. Beware of situations where the party supplying the compressor refuses to guarantee performance of the lube supply or lube injection modules or where supervisory instrumentation isn’t clearly specified. Downstream concerns can be overwhelming in those instances, and wrestling with them can be costly and time-consuming. They often end in litigation.