Building a more-efficient compressed air system

This case-study article reports on a project that was conducted at a 400,000-square-foot manufacturing plant in Smithfield, NC, to determine and quantify specific opportunities to improve the efficiency of, reduce the operating costs for, and optimize the operation of the compressed air system.

The plant normally works four overlapping 10-hour shifts, four days a week, with additional production scheduled as required. The plant also is projected to substantially increase production in the near future.

For this project, the objectives were to determine:

- kWh consumption, peak kW, and overall efficiency of the total compressed air system

- kWh consumption, loading, and efficiency of each air compressor

- System air leakage and pressure variations

- Compressed air kWh and cubic feet of consumption per product produced

- System control and compressor operating sequence.

Methodology

For this study, two AutoPilot panels were installed in two air compressor rooms for four weeks during April 2017 to continuously monitor and report kWh consumption, kW demand, inlet and discharge temperatures and pressures for each compressor, system airflow, individual compressor and total system efficiency. Sensors were installed to measure and record running load amps (RLA) and inlet and discharge air temperatures for each compressor, plus RLA for two air dryers, airflow, discharge pressures in each compressor room, and plant pressure.

Energy use for each compressor was determined by manually measuring the voltage when it was running and when it was off. Voltage remained nearly constant at 490V. Split current transformers were installed on each air compressor to measure amps. The software calculated kVA for each compressor and the total system.

The accuracy of the compressor data was confirmed by comparing compressor kVA with Duke Energy Meter kW data. As a result of the small difference between compressor kVA and kW, we have treated them as equal for the purposes of this study. More detailed analysis would not have changed our findings, recommendations, or estimated savings.

Finally, standard AutoPilot analytics and real-time and historical graphs and reports automatically calculated and displayed consumption, demand, inlet and discharge temperatures and pressures for each compressor, system airflow, individual compressor and total system specific efficiency.

Results and observations

For this study, observations were organized into 10 areas.

1. Peak kW. Meter 1 peaked at 745 kW on Wednesday, April 26, at 12:15 p.m. The coincident value for compressors 1-3 was 221 kVA, or approximately 200 kW. Meter 2 peaked at 326 kW on Saturday, April 29, at 5:30 p.m. The coincident value for Compressor 4 was 113 kVA, or approximately 100 kW.

With reduced air leakage and improvements in operation and control to increase system efficiency, the total system peak kW could be reduced by 110 kW. Because the meters peak at different times, the reductions in each are not directly additive.

2. System efficiency. The inability of compressors 1, 2, and 3 satisfy plant loads resulted in adding a fourth compressor in January 2017. At that time, a 4-inch piping loop was installed to feed all of the existing supply lines throughout the plant.

Two airflow meters were added for this study. Airflow Meter 1 was located on the 2-inch header leaving the Air Dryer in Compressor Room 1 to measure the total cfm from Compressors 1, 2, and 3. Data showed that, depending on the combination of compressors running and their loading, the combined specific efficiency of the three compressors could vary from 30 to 80–90 kW/100 cfm.

Airflow Meter 2 was located on the 2-inch discharge from the air dryer serving Compressor 4 only. Data showed when fully loaded, Compressor 4 ran at an efficiency of 28–30 kW/100 cfm.

The average efficiency of the total system is presently 40 kW/100 cfm, yet this could be increased by 30% to 28–30 kW/100 cfm through identified corrective actions.

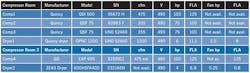

3. Compressor efficiencies. The airflow meter in Compressor Room 1 measures the total airflow produced by three compressors. Determining the efficiency of individual compressors was done by examining periods with different combinations of compressors running at different loads (see Table 1).

We never encountered a period when Compressor 1 was running with both compressors 2 and 3 off. On production days, Compressor 1, the largest of the three, was run 40% loaded most of the time in combination with one or both of the others. Whenever Compressor 1 was run fully loaded, the combined efficiency of the three compressors was high no matter how the other two are loaded. Compressor 2 normally runs near 50% loaded, and Compressor 3 is frequently cycled off and on.

Compressor 4 is normally run about 75% of the time, fully loaded. When Compressor 4 delivers 400 cfm and runs at 100% of the rated full-load amps, its specific efficiency remains near 28 kW/100 cfm. When it delivers less than 400 cfm, it still uses from 100-110 kW but quickly loses its efficiency.

4. Air leakage. From data collected during nonproduction periods when there is no requirement for compressed air, it is clear that leakage was 400–420 cfm depending on system pressure. To satisfy that leakage, the existing compressors as presently controlled consume a minimum of 100 kW and a maximum of 200 kW depending on which ones are running and how they are loaded.

The actual compressed air needs of the facility can be determined under all operating conditions only after air leaks have been repaired. At an average specific efficiency of 40 kW/100 cfm, reducing the air leakage by 90% or 350 cfm would provide an annual savings of more than 800,000 kWh or $60,000 at present electric rates.

5. System pressure. Whenever Compressor 4 is running, the pressure is 120 psi. Data shows that when compressors in Room 1 are running alone, the system pressure drops below 100 psi. This is most likely due to undersized piping in Room 1. Operating pressures normally vary 10 psi. Much of this is also due to the piping restriction and the resulting frequent cycling of Compressor 3. The operation of the production equipment requires stable pressures (within 2 psi) to ensure quality.

It is recommended that production equipment be adjusted to run at the lowest acceptable pressure, which can be near 100 psi according to plant engineering. Increasing the piping size, installing the correct fittings, and adding a VFD and compressor control system will allow the system to operate at the desired pressure and maintain a stable system pressure. Additional storage capacity may be required if the other recommended improvements do not completely eliminate the wide swings in pressure.

6. Capacity control. The only capacity control on any of the four existing rotary screw compressors is unloading. The data showed that when they are run near full load, their efficiencies are all from 28-35 kW/100 cfm. When run partially loaded, the efficiencies quickly drop. The kWh and cost per 100 cfm has been measured at 2-3 times that when fully loaded. With the compressed air leakage reduced by an estimated 350 cfm, the minimum airflow will be reduced to 250 cfm – well below the rated capacity of all of the compressors.

To maintain compressor efficiency under all operating conditions, it is recommended that a variable-frequency drive be added to Compressor 2, a 75 hp rotary screw rated at 355 cfm.

7. System control. According to plant engineering, the compressors are controlled by maintenance personnel manually turning them on and off. When on, they are loaded and unloaded by pressure switches. It was difficult to determine any defined operating sequence, as different compressors were started and stopped at different times in different combinations.

With air leaks fixed and the system continuously controlled, monitored, and maintained at peak condition, any two of the four existing compressors can meet the peak system demand at present production levels. Using the following proposed new sequence of operation, and with a new VFD on Compressor 2, the system will maintain an operating efficiency of under 28 kVA/100 cfm:

- All compressors will be off when there is no need for compressed air.

- Upon call for compressed air, Compressor 2 will start and vary its speed and capacity to match the load until it exceeds its capacity, 350–400 cfm.

- Either Compressor 1 or 4 will turn on and run until the load exceeds its capacity, 400–475 cfm. Compressors 1 and 4 will be alternated as primary.

- Compressor 2 will start and vary its speed and capacity to match the load until it exceeds the capacity of the two operating compressors, 750–800 cfm.

- A similar sequence will be used in starting the second 100 hp compressor and shutting off the 75 hp compressor if needed. With a maximum requirement for compressed air of near 800 cfm, the two 100 hp compressors may be able to handle the peak load.

As the production and corresponding requirement for compressed air continue to increase, the modified and improved existing system will be able to satisfy plant demand until the maximum requirement increases 50% to 1,200 cfm. This will delay the need to purchase additional compressors to provide adequate reserve capacity.

8. Air piping. The piping in Compressor Room 1 was originally designed for two 75 hp compressors. When the 100 hp compressor was added, the piping was not increased to accommodate the increased flow. Each compressor has a 2-inch discharge line and all tie into a 2-inch header with crossing tees, thereby creating a turbulent, high-velocity backpressure problem. The header size needs to be increased and the connections replaced with directional angle fittings to provide the projected savings.

9. Ventilation. Data shows the intake air temperature in Room 1 exceeds 110°F and discharge temperatures of fully loaded compressors exceed 180°F. These conditions will reduce compressor efficiency, shorten compressor life, and add moisture to the compressed air. The compressor areas need to be ventilated to prevent excessive operating temperatures.

10. Contamination. When the compressors in Room 1 are started, cycled, or all run together, the CFM meter stops working until the system stabilizes. The manufacturer was consulted and the problem was diagnosed as the presence of a fluid other than air in the piping. Because of the excessive temperatures, undersized piping, and perhaps maintenance problems with the equipment, it’s most likely that oil or water droplets were in the discharge air. It is recommended that a sensor be added downstream of each air dryer to detect liquid in the air lines. The source of the problems needs to be identified and repaired.

Conclusion

The daily kWh consumption varied depending on the day of the week and production schedules, from a high of 6,000 kWh to a low around 3,000 kWh. In 2016, the average was 4,150 kWh/day or 1.52 million kWh/year, at a cost of $112,000.

Recommended improvements with an estimated total cost of $95,000 include:

- Reduce air leakage by an estimated 90% or 350 cfm

- Add one variable frequency drive

- Add monitoring and control system

- Improve piping

- Install a ventilation system

With the present plant operation and production, the recommended improvements would reduce the kWh consumption more than 60% to an average of 1,365 kWh/day or 498,000 kWh/year. At the 2016 average rate of $0.074/kWh, the annual cost will be reduced to $36,700, for an annual savings of $75,000 (or 65% of current cost). The simple ROI is estimated to be 15.2 months.

Note: The graphs to accompany this report can be viewed at http://www.holmesautopilot.com/wp-content/uploads/2018/09/Compressed-Air-Demo-Project.pdf.