How a facility manages its compressed air condensate influences operational reliability and, because of the hazardous waste that condensate contains, affects a plant’s impact on the environment. It’s important that compressed air systems have a condensate management network in place. Knowing the environmental factors that produce more or less condensate, understanding the drain and piping systems, and identifying what condensate is made of are integral to properly maintaining a compressed air system.

How condensate is formed and managed

When atmospheric air is compressed, the amount of water that can exist in a vapor state is reduced, causing the surplus water to condense into a liquid. This water mixes with other airborne constituents consumed from the environment along with traces of lubricant/coolant from the compressor. The resulting emulsification is referred to as compressed air condensate.

The volume of condensate that is extracted from a compressor is based on the difference between how much water was present in the atmospheric air ingested into the compressor and how much water can remain in a vapor state at the temperature and pressure of the compressed air. Consequently, a compressed air system will generate more condensate on a hot summer day than on a cold winter day.

Picking the right condensate drain

Choices abound when it comes to drain manufacturers, but there are only a few common types of drains for compressed air systems.

Drains can be categorized as manual drains, timer-based drains, or capacity-sensing drains.

- Manual drains are a simple valve and are best-suited for particulate filters in areas where condensate is low or nonexistent. These drains require periodic draining by an operator, but quite often no liquid is found.

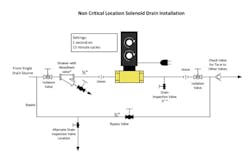

- Timer-based drains are typically solenoid or actuated-ball valve-type drains with a fixed or adjustable timer. Although these drains are typically lower in cost, some are reasonably robust and are less prone to failing. The drawback is that these drains cycle only based on time, so they either discharge too frequently, which wastes compressed air, or they cycle infrequently, allowing condensate to collect and carry over into the system.

- Capacity-sensing drains are the most efficient and adaptive type of drain, discharging only after a fixed volume of liquid has collected in the drain. These drains can function using some form of electronic sensing or can be completely mechanical using a float-type mechanism.

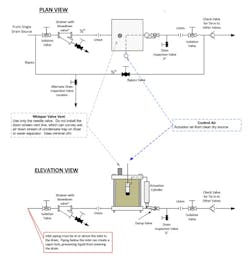

Some low-cost units can be sensitive to contamination and may fail easily due to obstruction. This needs to be considered during the purchase process, with purchase directors weighing both application conditions and the degree of maintenance required. One common issue to be aware of is the use of strainers installed ahead of a drain valve. In theory, the strainer will collect larger particulate and protect the drain from failing because of obstruction, but the strainers often are neglected and become clogged. It’s important that if a strainer is installed, a manual valve and piping arrangement also be installed ahead of the drain to facilitate easy isolation for servicing and testing.

Proper piping to move condensate

Condensate piping must be configured to facilitate easy removal of every drain for service or inspection. A bypass should be installed on the discharge side of every drain to support testing the drain operation. This should include a tethered hose for systems to periodically test the condensate discharge rate using a scaled collection device over a fixed period of time.

The quantity of condensate removed from the compressed air system will change based on the volume of compressed air consumed and the ambient conditions. On a hot summer day, a 100-horsepower compressor with a refrigerated air dryer can generate more than 45 gallons of condensate in an eight-hour shift. The same system during a subfreezing winter day would generate less than one gallon of condensate during a shift. Some maintenance programs may periodically measure the rate of condensate removal relative to operating conditions to establish a performance baseline. This data could be used to identify a deviation from the desired performance and facilitate a more prognostic approach to maintaining compressed air system performance.

It is a good practice to periodically test condensate for concentration of major constituents and pH level. This data can be helpful in troubleshooting quality issues associated with contamination. It is not uncommon to assume that compressed air condensate is the source of contamination for a process-related issue only to find that the actual source of the problem is a local airborne pollutant or lubricant. This is a common misdiagnosis in paint applications that can be very sensitive to silicone or hydrocarbons.

Know your condensate and practice safe disposal

Compressed air condensate can be acidic or basic depending on the environment. This can affect the rate of material degradation or corrosion. Having a good grasp on your condensate properties is valuable when selecting compressed air system materials such as piping, plastic tubing, valves, and fittings. Condensate should be tested during both the summer and winter to account for changes in the concentration of water present in the atmosphere. When attempting to diagnose an issue associated with the presence of specific compounds in the condensate, sampling frequency may also need to take into account wind and the ingestion of airborne contaminants from processes outside of the compressor’s intake. Depending on the chemical compositions of neighboring exhaust, temperature inversions may also be influential, causing an increased density of contaminants during morning hours when the ground is cold and air temperatures start increasing.

Compressed air condensate is an emulsification of water, hydrocarbons, and other potential airborne contaminants; therefore, it’s considered a hazardous waste and must be processed accordingly. Condensate cannot be discharged directly to a municipal sewage system and must be treated to reduce the concentration of contaminants to an acceptable level. Some facilities have a central wastewater treatment process that can treat the waste, but it’s important to consider the cost associated with treating the condensate compared to other methods.

One alternative option is to use a condensate separation product dedicated to the air compressors to reduce oil from condensate down to an environmentally acceptable level. It is important to investigate details regarding the type of oil introduced into the condensate and the requirements to separate it from the water. Some oils will separate based on dwell time, while others may require chemicals to separate the oil from the water. Some may choose a distillation-type product that uses an electric heater to boil the water off as steam, leaving only residual waste liquid to be processed as hazardous waste. For some installations, there is no access to a drainage system, so the water from the oil/water separator is discharged through an exterior wall and allowed to pool in the soil. Unfortunately, the water is not pure and will typically still have low concentrations of oil. Over time, the water will evaporate, leaving behind the oil. Eventually, enough oil will accumulate for the soil to be classified as hazardous waste, requiring costly disposal.

Mark Krisa is global air system performance leader for Ingersoll Rand Compression Technologies and Services.

Having a condensate management process, key data about a manufacturing facility, and awareness of temperature conditions will give maintenance staff the opportunity to address a system’s performance and issues before big problems arise. Proactively correcting condensate issues can help reduce excess condensate from carrying over into the network, saturating the piping system and contaminating production equipment. These factors will help facilities abide by hazardous-waste regulations and optimize the reliability of their compressed air systems.

[sidebar id="6"]