More and more industrial compressed air users are embracing a systems approach with respect to energy efficiency. Gone are the days of simply comparing the electrical efficiency of compressors and buying the one with the lowest input energy. Smart operators are looking beyond individual components. They are beginning to understand that true efficiency is more than the sum of the system’s parts – it’s how everything works together as a whole.

We’ve seen this with system master controls ushering in the industrial internet of things (IIoT), carefully orchestrating interplay between system components to ensure energy efficiency and make predictive maintenance possible. And it’s not just “new” technology that a systems approach makes possible – it's also ideas that may have been around for awhile but hadn’t been thoroughly considered or acted on.Industrial compressed air users are also getting more aggressive about managing leaks, reducing operating pressure, and finding alternatives to using compressed air for some applications. The results are stronger, leaner, and more-efficient compressed air systems.

Here’s a rundown on how much you might save from that twin 250hp (approximately 2500 CFM) system with a blended electrical rate of $0.10/kWh and an annual electrical cost of $328,500. Using U.S. Department of Energy estimates, savings would be as follows:

- Fixing leaks = $98,550

- Reducing pressure = $32,850

- Eliminating artificial demand = $32,850

(System is now at 1250 CFM.)

Savings from split system and master controls = $41,062.50

(Annual electrical cost now at $123,187.50)

Heat recovery offset gas cost = $61,593.75

Total annual savings = $266,906.25

There is another opportunity for major energy savings in compressed air; however, it depends on thinking about compressors in a different way. So let’s shift a paradigm and save some money while we’re at it.

These are not the compressors you are looking for

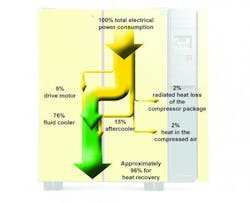

For users and system designers to expand their systems approach and take the next big leap in cost reduction requires embracing a new paradigm: Industrial compressors are just electric heaters that happen to make compressed air. A system with two 250 hp compressors, then, can be thought of asa 375kW heater. Taking a 375kW air heater (air-cooled compressors) and venting it to the outside all year long makes no economic sense. Taking a 375kW water heater (water-cooled units) and running the hot water to a cooling tower to vent the heat to atmospherebefore reheating the cooled water, only to cool it again, is even worse.

100% of all the power consumed by a compressor is turned into heat. 96% of it is available for recovery, making the case for thinking of a compressor as a heater.

A little bit of physics goes a long way

To make this paradigm shift, it is important to understand a bit of physics. All of the input power to a compressor is converted to heat – all of it. That input power does not add any energy to the air. This often prompts the question, “If all of the input power were converted to heat, how is any energy left in the compressed air to do work?” The simple answer is that the energy was already there before the air was compressed. The fact is, at the same temperature, 1 pound of air at atmospheric pressure contains exactly the same amount of energy as 1 pound of air at 100 PSIG.

Air at a temperature above absolute zero contains energy. If air is at 60°F, it is really 521° above absolute zero. We can use gas laws to find that 1 pound of air requires about 123.7 BTUs to heat it from absolute zero to 60°F. That is the intrinsic energy of 1 pound of air at 60°F.

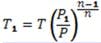

When air expands, it gives up heat. When air expands from 100 psig to atmospheric pressure (14.7 PSIA), its temperature will drop by about 231°F. Here is the formula for calculating the temperature change:

T1 is the absolute temperature after expansion

T is the absolute temperature of the air before expansion

P1 is the absolute ambient pressure in pounds per square inch

P is the absolute pressure of the compressed air in pounds per square inch

n is the ratio of specific heat at a constant pressure and specific heat at a constant volume (1.4 for air)

{pb}

Ducting and tapping into the fluid circuit of compressors is an excellent way to utilize a compressor as a heat source and reduce operating costs.

That 231°F temperature change means the expansion has released about 54.9 BTUs (of the 123.7) per pound of air. That is equivalent to about 42,700 foot-pounds of energy. It is this release of energy by the expanding air that does the work in a compressed air system.(Unfortunately, pneumatic devices and tools rarely allow complete expansion internally, and much of the available energy is lost at the exhaust port.)The power used to compress the air does not factor into the work that the air can do. The available power to do work in a compressed air system is a function of pressure, temperature, and mass (related to CFM flow).

The temperature of air increases as it is compressed and decreases as it expands. That increase in temperature is equal to the amount of energy required to compress the air. Once compressed, most of that increased temperature is usually treated as waste and removed through various coolers, dryers, receivers, piping, and ventilation.

Our short physics lesson is over. The takeaways are that the work done by compressed air is a function of the heat it gives up as it expands, and all of the input power to a compressor gets converted to heat. Understand this and the paradigm shift is simple.

Turning potential savings into real savings

When dealing with existing systems, many compressors can be retrofitted with external heat exchangers for heat recovery.

To turn the potential savings into real savings requires a few planning steps. First, collect data. Determine how heat is generated in the facility. Calculate the annual cost of heating water and heating air. Calculate the annual energy cost of the compressors in the system. Compare these two numbers. The best savings potential will be in facilities where the cost of heating water and air exceeds the cost of running the compressors. Where the cost of running the compressors exceeds the cost of heating water and air, less savings will be possible because the compressors are generating more heat than is being used in the facility. Still, much of the heating cost can be offset by recovering the heat from the compressors.

Second, identify suitable uses for the heat. Look at everything. Enlist the help of other employees to identify potential uses for heat, especially when conducting an Energy Star Energy Treasure Hunt. If there is a boiler, preheating the water will reduce the energy that the burners require. Are products being washed and dried? That may be an application for hot water and/or hot air. Any application that requires heating water is a good fit for heat recovery. This may include boiler feedwater, parts cleaning, clean-in-place for food processing, heating products to improve flow characteristics, showers, washrooms, kitchens, etc. Hot air can be used for space heating, product drying, HVAC makeup air, etc. Look at all plant applications that require some type of heating. Determine the variations in heat demand that exist during the day, week, month, or season.

Wayne Perry is senior technical director at Kaeser Compressors and has more than 35 years of experience in all aspects of the compressed air business.

Third, determine the available heat energy. Not all compressors run fully loaded all of the time. In a well-orchestrated compressed air system, some compressors will probably be running fully loaded and some will be trimming. The trim compressors will have available heat that varies with the load on them. A variable-speed compressor running at 40% capacity will not have the same heat recovery potential as one running at 85% capacity. The best way to determine the available heat energy is by data-logging the kW consumption of all of the compressors over a representative period of time. Consider working with a reputable compressed air expertto conduct a comprehensive compressed air assessment to help you determine your system’s energy and demand profile. This data will be important for the next step.

The fourth and last step is to match the heat source with the heat use; this may require an engineered approach. Don’t be afraid to consult an expert to ensure proper design and application. If the compressors run most heavily loaded on the first shift and the demand for heat is heaviest on the second shift, some type of storage may be required. If the demand for hot water varies, an air-cooled compressor with a water-cooled heat recovery package may be needed. When the demand for hot water is low, the compressor could use its air-cooled heat exchangers to maintain a proper temperature. When the demand for hot water is high, the water-cooled heat exchangers would be used.

Although compressor heat recovery can be a direct BTU for BTU tradeoff, it is not a direct dollar for dollar tradeoff. Usually, heat in a facility is produced with natural gas or some other fuel that is less expensive than electricity. Still, it is possible to see savings of as much as half of the compressor energy cost. Keeping this in mind, along with taking a systems approach, should help shift the paradigm – and shift money back to your bottom line in the process.