Trying to coordinate control of compressed air systems can be a frustrating experience at best, especially if there are multiple compressors located in different compressor rooms. If your compressed air system is controlled manually and you set up a control strategy using local compressor pressure settings, odds are that your system is consuming a lot more energy than it needs. Addressing this issue can not only reduce your power bill but also give you more-reliable and stable air pressure.

How do compressors control pressure?

We'll focus here on the control of rotary screw compressors, the most common kind found in industrial plants. The strategies discussed here may or may not apply to systems with centrifugal compressors.

Pressure is the most important parameter in a compressed air system. If the level is not maintained above the minimum required pressure, then compressed-air-powered machines will start to malfunction, affecting production. In a perfect world, you could set your compressors exactly at the minimum required pressure and they would control themselves, starting and stopping, loading and unloading, to maintain perfect pressure output at optimum energy consumption. But, the world of compressed air is far from perfect, and the biggest problem is pressure differential.

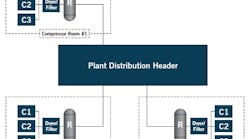

Consider Figure 1, which is a simplified diagram of a compressed air system. The compressors in this system control the pressure at location P1. If left to control the pressure with a typical cascaded pressure band arrangement (pressure set points overlapped by 5 psi), these compressors would provide a pressure of, say, 100 psi when both are fully loaded and perhaps 115 psi during the lightest loads. But it's important to understand that it is not the pressure at point P1 that's important. The pressure at P6, right at the critical end user, is the location that should be controlled accurately. Real-world conditions conspire against this requirement, however.

A real-world system has pressure differential across system components. At full load, there may be 4 psi across the filter, 6 psi across the dryer, 5 psi drop in the system piping and 15 psi drop across the filter, regulator, lubricator (FRL), hoses and connectors. This leaves the critical user with only 70 psi of air pressure during the worst-case scenario, system full load, when the compressor discharge pressure is being controlled at 100 psi. During light loading conditions, because the pressure differential drops with lower flow, the pressure at the critical user may float as high as 115 psi, depending on the local regulator setting.

Can the compressor control help stabilize the pressure at the critical end user? No, because the compressors are controlling the pressure at point P1. Therefore, as system loading varies higher or lower through the course of the day, the pressure at the critical user points P4 to P6 will vary widely. This wide variation can cause inconsistent production output if the end use is pressure-sensitive, or it can shut down the operation completely. To solve these problems, compressed air operators will artificially increase compressor discharge pressure to compensate, say in this case by 10 psi, so that the pressure is well above the minimum requirement at full loading conditions.

Energy penalty for higher pressure

If this adjustment is made, then the compressors would regulate the pressure at a discharge to between 110 and 125 psi through the changing loading conditions. This higher pressure, though, comes at a price. As a general rule of thumb, at around 100 psi, the power consumed by an air compressor increases by about 1 percent for every 2 psi in discharge pressure increase. Also, for every 1 psi increase in pressure, the flow consumed by unregulated compressed air users goes up by slightly less than 1 percent. This higher flow further increases the compressor power consumption by a level that depends on system characteristics.

The higher pressure may also cause other efficiency issues. A common maximum pressure rating for air compressors is 125 psi. Perhaps as the filters in the system age and get clogged with dirt, system operators must increase the pressure at the compressor discharge to compensate. But if this is done, the compressor will exceed its rating, which would overload the motor and activate over-pressure protection. This higher pressure may also require the compressor to operate in modes such as modulating control that are inefficient at partial loads.

Multiple compressor rooms

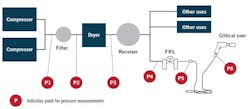

If more compressors come into the picture – perhaps as with multiple compressor locations in a system set up like Figure 2 – then the problems multiply. Each compressor room would have different loading conditions and different pressure differentials. The plant distribution header might have a different pressure on one end than the other. But to control the system efficiently, the compressors in one room must be properly coordinated with the other rooms. To properly coordinate the air compressors with local compressor set-point adjustment, a very wide pressure band would be required. In systems with widely varying loads, this coordination is pretty much impossible unless the compressors somehow share the load with the units running at partial loads.

Part loading is inefficient

One incorrect strategy that might be employed would be to set all the compressors to the same pressure setting so they all share the load. All the compressors would maintain the system pressure within the same pressure band and would share the system load. This may be simple to accomplish but it comes at a huge energy penalty. A typical fixed-speed rotary screw compressor is the most efficient a full load (or turned off).

Running a compressor say at 30% load might consume about 60 to 80 % of full load power. Running three compressors all at 30% load may consume twice what one fully loaded compressor would consume while feeding the total flow. Implement this strategy with nine compressors and the energy bill goes through the roof.

In any system, the optimal control strategy should be to keep all compressors except one fully loaded. The compressor that takes the partial load (called the trim compressor) would be selected by assessing which compressor has the best part load efficiency (load/unload, VSD or variable capacity control. Perhaps this decision could be made automatically.

Moving the sensing point and automating control

To accomplish optimized control the pressure the compressors are using to control the pressure must be consolidated to one common value. Attempting to accomplish optimal compressor control based on different varying pressure differentials that change over time is just an exercise in futility. The first step in accomplishing optimal control is to ensure all the compressors in a system are “seeing” the same pressure. For example, in Figure 1 we would want the compressors to control the pressure at point P3, or if practical P4. Further to this, if there are multiple compressors in multiple compressor rooms, some kind of sensing and automation system that controls the pressure from a central pressure point in the system would be desired. This type of control usually involves system master controls that would orchestrate system wide compressor control based on one or more critical system pressure points.

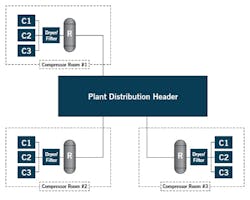

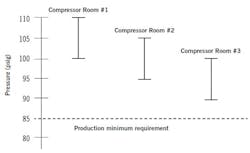

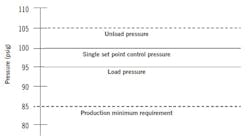

Figure 3 shows a typical cascaded pressure strategy that would ensure that all the compressors except one unit will be running at full load. You can imagine if there were nine compressors to control, you might run out of pressure range at the top and bottom end of the band. Figure 4 shows the typical single pressure band that might be applied using system master controls. With this strategy, the pressure band remains the same with any number of compressors. Control would add a compressor if the pressure fell below the lower set point and remove a compressor should the pressure go high. If one or more VSD-controlled compressors were employed in the system, the controllers typically would set the target pressure midway between the load pressure and the unload pressure.

Beyond promising optimal compressor control, some of today's master control systems also perform other functions, such as controlling auxiliary systems and doing system energy reporting. These systems will get only more sophisticated and adaptable as time goes on. Currently, however, almost all perform the basic system control just described: keeping all required compressors fully loaded except one trim unit. The other compressors are turned off, minimizing unloaded run time and improving system efficiency.

Elimination of pressure differentials

A sharp-eyed reader may have already realized that controlling the pressure at point P3 or P4 may not completely solve the pressure differential problems that may exist at P6, right at the critical user. But there could be hundreds of critical users in a plant, and it would be impossible to control compressor compressed air system pressure for every one of them. It is possible, however, to improve the situation substantially with proper design of system components that feed the end use.

Most often the filters, regulators, hoses, and connectors for compressed air tools and equipment are selected because they are a standard available size used in the plant. Installation is often done without regard to the actual peak demands of equipment connected at the far end of the hose. Connecting a large air-powered impact wrench at the end of a long piece of ¼-inch hose, for example, might result in extreme pressure differentials exceeding 50 psid and very poor tool performance. Upgrading component sizes to match the peak tool requirement might result in less than 10 psi pressure differential and pressures that better track the control point pressure at point P3 or P4.

In a similar vein, reducing the pressure differentials between point P1 and P4 by upgrading filter styles to low differential, upsizing air dryers, and increasing piping capacity brings point P1 closer to that of P3 or P4. The result: lower compressor discharge pressures and lower energy consumption.

[sidebar id="6"]

In the real world

Thousands of systems have been optimized across the world across the world using properly installed and maintained system master controls. The following is just one of them:

A large foundry had a system of four large 100 psi-rated 150 hp compressors located in two compressor areas. The plant load varied widely, with only one compressor required during weekend downtime, while peak loads during full production required three and sometimes four compressors. The compressed air was conditioned by general-purpose filters and refrigerated air dryers.

The sensing point for all the compressors was located within the compressor package on the minimum pressure check valve. Because of this location the compressors had to “look” through the pressure differentials represented by the compressor air aftercooler, the filters and the air dryer. Desired minimum system pressure was 85 psi. The highest the compressors could produce at full load was 100 psi. Pressure differential across dryers and filters was 7 psi, this left only a 7 psi pressure band within which the four compressors could be controlled.

Attempts were made to improve the compressor control by cascading the pressure bands, but the compressor service personnel gave up in frustration. The staff selected the easiest method of compressor control, inlet modulation, for all the compressors. This strategy kept three compressors running even at times where one could do the job. Staff tried turning off the compressors manually; however, this negatively affected the reliability of the system pressure. Many times, unanticipated peak loads or short-term equipment outages required compressors to be turned on when staff was not on shift, and the result was unstable system pressure. This affected plant production. Other times, staff members simply forgot to turn compressors on or off. A compressed air auditor assessed the system, and baseline energy was found to be 4 million kWh per year – almost twice what was required for the actual plant load.

The company upgraded its compressed air system by installing three new compressors, including a VSD-controlled unit. A new master controller coordinates the compressor operations, ensuring the VSD compressor is always supplying partial loads, while the fixed-speed base compressors remain fully loaded. When the load drops, the base units are turned off, and they remain on standby for any unanticipated event that might require additional capacity. Pressure control is maintained within a 10 psi pressure window. Air dryers and filters were upgraded to lower pressure differential, which saves energy. Plant pressure reliability and stability has been improved with the addition of a control option where the pressure is sensed at both ends of the system and fed into the master controller. This optimal control has reduced energy consumption by 45% and saved 1.8 million kWh per year.

Transit bus manufacturer

A large transit bus manufacturer grew over the years as facility production capacity expanded. There wasn’t room in the main compressor room to install the required 100 to 200 hp screw compressors, so additional units were installed in two other locations at both ends of the plant. The plant has a very high peak load because of sand-blasting operations that are needed to condition the vehicle frames before painting. All compressors except for one large spare were required during peak production activities, but only one compressor is needed during low weekend loading.

The configuration of the compressors in three locations made it difficult to coordinate the operations through the widely varying flow requirements. A mixture of modulation and load/unload control was selected but, because of air dryers and filter pressure differentials, it was difficult to maintain both good pressure control and optimal energy consumption. Baseline energy and flow measurements showed that the plant was consuming 2.16 million kWh, more than twice as much energy as was required to maintain adequate system pressure.

The system was improved by relocating compressors and consolidating units so that there were only two compressor locations. This made good manual compressor control possible, and this approach was successful for many years. As time went on, however, control deteriorated to old, inefficient ways as staff changed and settings became poorly adjusted.

An upturn in production requirements allowed for a system upgrade in which three new compressors, including one VSD-controlled compressor, were installed. A master controller was installed to coordinate the operation of the two compressor rooms. During high plant flows, large compressors are operated to feed the plant, as these are more efficient. When production levels drop, smaller compressors that better match low system flows are employed, minimizing energy consumption. Dryers and filters were sized to minimize pressure differential; this reduced the required compressor discharge pressure. In addition, pressure sensors were installed at each compressor room to ensure the systemwide pressure remains within desired limits. Overall energy consumption has been reduced by 52%.

Is your system efficient?

If you don’t know how your compressors are controlled, ask. If nobody knows (a very common occurrence), you likely have an energy consumption problem. Compressed Air Challenge offers Fundamental and Advanced compressed air efficiency training designed to help operators become more adept at managing their facility's compressed air use. Armed with a better understanding of the hows and whys of compressed air, you'll be in a better position to improve your compressed air system's efficiency.