In brief:

- Condensate shortens the life of compressed air-operated machinery and can contaminate product causing significant maintenance costs and loss of productivity.

- The most effective way to eliminate the demand side open drainage is to install dryers and filters at the air compressors.

- There are four different types of drains — the manual valve, the level operated mechanical trap or float drain, the electrically operated timed-solenoid drain, and the no-air-loss auto drain.

Plant Services surveyed readers over the past two years about the management of their compressed air systems. More than 100 individuals participated in each survey.

Three-quarters of respondents were plant managers, maintenance managers, manufacturing managers, supervisors, or plant engineers. These were the top five job titles of respondents both years. No other job title accounted for more than 6% either year.

More than half of the respondents worked in food & kindred products; chemicals and allied products; fabricated metal products; or miscellaneous manufacturing industries. These were the top four industries of respondents both years. No other industry accounted for more than 8% either year.

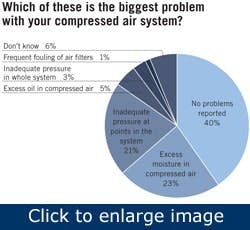

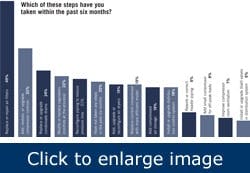

Two-thirds of this year’s respondents said they operate air compressors 24 hrs/day, 7 days/week, which was up by 8% over the previous year. The biggest problem reported in the survey was excess moisture in compressed air. Among the most common maintenance steps were replacing or repairing air filters, the top step, reported by almost half of participants, and replacing or upgrading condensate drains, the third most common at 24%. Here are the survey highlights.

If allowed to flow out into the compressed air system, condensate shortens the life of compressed air-operated machinery and can contaminate product causing significant maintenance costs and loss of productivity.

Plant personnel do their best to protect air-operated equipment and product by filtering the air at the end use; however, this means they must drain and change filter elements in multitude of filters on a regular basis. To minimize this workload personnel will often crack open the petcock on the filter housings and drain valves on drip legs creating what the compressed air industry refers to as open drainage or intentional leaks. The compressed air industry uses these terms to describe leaks that can be reduced or eliminated by installing automatic drains at those locations.

The most effective way to eliminate the demand side open drainage is to install dryers and filters at the air compressors; however, one should only dry the air to the level required; therefore, some industrial sectors such as chemical plants, refineries, paper mills, and glass plants only dry a portion of their compressed air. Typically, there will be intentional leaks in the wet air headers of these plants that can be reduced or eliminated by installing automatic drains.

Intentional leaks are also found on the supply side of the system, where they are draining condensate from compressor intercooler and aftercooler moisture separators, filters, and refrigerated dryers. It’s critical to drain the condensate from these devices to prevent damage to compressors and dryers, particularly desiccant dryers, and to improve the quality of the air flowing out into the plant. In fact, if you don’t drain the condensate out of pre-filters on desiccant dryers or the separator in a refrigerated dryer, it doesn’t matter what type or size of dryer you install; you’ll have poor quality air.

There are four different types of drains — the manual valve, the level operated mechanical trap or float drain, the electrically operated timed-solenoid drain, and the no-air-loss auto drain. Each type of drain is offered in various styles.

Manual valve

While the most common manual drain valve is the ball valve, we have probably seen every type of manual valve used to drain condensate from the system. Theoretically, one may think the manual valve can be opened once a day or once an hour so there won’t be much waste, and, in some applications, such as an air receiver, this works. But from a practical standpoint there is too much risk of either damaging the compressed air equipment or ending up with poor quality air with this manual approach, so personnel typically leave them leaking a small amount of air all the time. Other than making sure the manual valve is open enough so it doesn’t plug up or open too much that it freezes up, the manually cracked open method is probably the most reliable drain and basically requires zero maintenance. This method wastes significant amounts of energy, and, even though it increases operating costs, it’s still commonly used.

Level operated mechanical trap

The two most popular level operated mechanical drains are the float drain and the inverted bucket trap. Neither of these styles of drains wastes air when operating properly, but they often require a great deal of maintenance and are prone to blockage from sediment in the condensate. As a result these style drains either fail open and waste compressed air or fail closed so personnel don’t realize there’s a problem until moisture shows up downstream. In addition, either style drain can waste as much or more air than a manual valve drain. While improvements have been made in float drains to make them more reliable, many of the same issues remain.

Electrically operated timed-solenoid drain

Years ago, personnel began migrating over to electrically operated timed-solenoid drains because they are typically more reliable than level-operated mechanical traps; however, they can, depending on the orifice size and settings, waste more air than a manual valve. In order to minimize the wasted air, they should be adjusted for only condensate drainage and minimal air drainage, but unfortunately the amount of condensate varies depending upon the compressed air system demand and the humidity. Constantly adjusting the drain times isn’t practical; therefore, the interval and duration of the electrically operated timed-solenoid drain is typically adjusted for worst-case conditions that occur during the most humid time of the year. The worst-case conditions may occur only for a month or two, so the electrically operated timed-solenoid drain wastes air for the other 10 months of the year.

Electrically operated timed-solenoid drains are the standard drain on most refrigerated dryers, and a moisture problem often is solved by adjusting the interval and duration of the electrically operated timed-solenoid drains on their dryers.

While one can purchase electrically operated timed-solenoid drains with smaller orifices, a ½-in. orifice is recommended for most applications to prevent the drain from plugging up. One air dryer manufacturer recommends setting the electrically operated timed-solenoid drain for an interval of 3 min and duration of 10 sec. Based on an estimated rate of flow of 270 scfm at 100-psi for a ½-in. orifice, the electrically operated timed-solenoid drain with these settings can waste as much as 15 scfm of average flow, which costs about $1,350 annually.

{pb}

Figure 1. The motorized ball valve is a version of the electrically operated timed-solenoid drain that is recommended for use on deliquescent air dryers and on wet air receivers.

The motorized ball valve is another version of the electrically operated timed-solenoid drain that is recommended for use on deliquescent air dryers; it’s also used on wet air receivers (Figure 1). During compressed air system reviews, 900 recorded scfm events were tracked back to the cycling of a motorized ball valve. Events of this magnitude can pull down system pressure enough to cause one or more compressors to start and run unloaded. If this happens, the operating cost impact can exceed the typical annual cost of the compressed air use by four or five times.

The motorized ball valve eliminates the need for someone to walk around opening and closing manual drains; however, the motorized ball valve actuator fully opens and then closes the valve, which creates a large event and wastes significantly more air than a simple manual operation.

No-air-loss auto drains

Recently, given industry’s focus on energy efficiency the no-air-loss auto drains have become popular. These are available in either pneumatic or electric-operated versions.

[pullquote]

The pneumatic version typically comes with a translucent housing so that one can view the operation of the drain to verify that it’s working. In many cases it can take hours for a no-air-loss auto drain to fill with enough condensate to cycle, so at least one manufacturer has an optional counter available that one can monitor to ensure that the drain is working. Yes, they have a push-to-test button; that’s a misnomer because it doesn’t actually verify that the auto drain will work on its own.

The electric version doesn’t have a translucent housing so it typically has an alarm light that indicates that the drain failed to operate.

Figure 2. The no-air-loss auto drain is designed to close with enough water remaining in the reservoir to prevent air from escaping.

The no-air-loss auto drain is designed to close with enough water remaining in the reservoir to prevent air from escaping (Figure 2). Air locks can sometimes prevent the condensate from flowing into the drains, particularly if gravity-fed, so one must either install a balance line or vent a small amount of air — a few cubic ft/hr — to the atmosphere. For the pneumatic version, the only air loss is the volume of air used for the valve’s actuator cylinder that bleeds out through an orifice sized to close the drain valve before air begins escaping. Some electric versions use capacitance probes to actuate the drain and to shut it off with a small amount or condensate left in the reservoir.

The benefits of no-air-loss drains include energy savings, recovering compressor capacity, and reliability.

At a blended rate of $0.05/kWh, the annual energy cost of 1 scfm is on average $90, so installing a no-air-loss auto drain on a 10 scfm intentional leak saves $900 annually, and if it’s replacing a ½-in. electrically operated timed-solenoid drain with a 3-min interval and 10-sec duration, it will save $1,350 annually. Typically, the list price for a good no-air-loss auto drain is around $750, so if plant personnel install the drain the simple payback is less than one year, and if a contractor installs it the simple payback is still only about 20 months. Therefore, installing a no-air-loss drain pays for itself; however, for a system with many drains, the biggest savings may come from recovering extra compressor capacity, which may allow you to avoid the cost of purchasing and operating that next new compressor, dryer, and associated equipment.

Are pneumatically operated no-air-loss auto drains reliable? While most of the pneumatically operated no-air-loss auto drains are bypassed at many plants, the primary reason for failure is that most aren’t installed correctly, which often can be blamed on man’s aversion to reading the instructions.

Some of the common problems with no-air-loss auto drain installations include:

- using wet air from upstream of the dryer, rather than dry air from downstream of it to actuate the drain

- not installing a filter in the control airline

- using a control air pressure that's too low

- using undersized piping between the device being drained and the drain, which can cause air lock blockages in the drain line

- using ¼-in.plastic tubing as a balance line (this line size allows moisture to block the line and prevent condensate from flowing into the drain; also, if the plastic tubing is too long it can sag allowing moisture to collect in the low spots and create an air blockage)

- drain isn’t level, which may prevent the drain from actuating

- neither the drain nor its piping are tied down (some drains can rise several feet above the ground and slam back down when the drain cycles).

Another reason so many no-air-loss auto drains are bypassed is that they’re given a very low priority when they require maintenance.

| Chris E. Beals is a designated Energy Expert for Compressed Air by the U.S. Department of Energy and is a founding member of the Compressed Air Challenge. In addition, Beals is a certified L1 instructor, was a member of the Core Technical Group responsible for developing the training materials for the Compressed Air Challenge seminars, and is president of Air System Management. Contact him at (303) 771-4839 or [email protected]. |

In addition, rust will reduce the reliability of most drains. In oil-free systems installed with cast steel headers, large quantities of rust will occur upstream of the dryers and in wet air headers or even downstream of the dryers if the relative humidity becomes high enough. We have also seen large qualities of rust occur between mist eliminators and dryers in systems using lubricated compressors. It’s interesting that we don’t see the same amounts of rust occurring between coalescing filters and dryers even though their DOP tests would suggest that the coalescing filter removes more oil. This rust can cause float drains, timed-operated solenoid valves and no-air-loss drains to fail, and even the manual valve is susceptible to failure because, if there isn’t sufficient flow, rust can plug the drain line between the device being drained and the drain. Installing drains in oil-free systems where the air upstream of the dryers isn’t saturated increases the failure rate of the drains.

In some cases, it’s best to use the manual valve and waste air; however, in the majority of cases, plants can and do significantly reduce energy costs and recover compressor capacity by installing no-air-loss auto drains. The installation issues can be overcome by either reading the instruction manual or having an experienced supplier install the drains. The reliability of the drain will vary with each installation. Finally, if you’re looking for a maintenance-free drain that doesn’t waste energy and lasts forever, stop looking. No matter what the drain salesman says, they haven’t made it yet.