Prepare to optimize a compressed air system, Part I

Organizations such as the Compressed Air Challenge have ushered in a new age for compressed air system operators. Gone are the days when it was normal procedure to add a new compressor when the system presented air pressure problems or when more users were added. The new standard is to optimize systems, both to cut energy costs and to squeeze as much capacity from the compressor as possible. But optimizing an air system is not something to be undertaken lightly. It takes time and effort to get a compressed air system into shape to meet the standards. At some point you may want to get some training or bring in a consultant. In the meantime, try these three easy, inexpensive ways to improve performance.

Cost of compressed air

Compressed air systems are expensive. Besides the cost of buying and maintaining a compressor, dryer and other components, simply operating the system costs a lot of money. A 100 hp compressor consumes about $36,000 in electricity annually if the plant pays an average of $0.05 per kWh for electricity. Annual system maintenance easily adds another $3,500. And if an inefficient system forces you to add capacity, you could spend $36,000 more on an extra compressor that will cost another $39,500 per year to operate.

Faced with these costs, it makes sense to reduce energy use wherever possible. One easy and inexpensive way to start optimizing your system is by reducing pressure drops.

Prime performance killer

Upgrading a system to operate effectively at lower pressure is an important first step toward optimizing a system. Pressure drops occur at every obstruction in the system. Pressure drops add up as air flows from the compressor to end-users. Because end-users require a certain minimum pressure to operate properly, the compressor must develop additional pressure to compensate for pipeline obstructions. To produce additional pressure, the compressor consumes additional power. A standard estimate is that each 2 psig increase in compressor discharge pressure burns up an additional 1% input power.

A symptom of excessive pressure drop is the complaint that tools and other end-users aren't working reliably. Start any investigation at these pressure-sensitive end-users.

Benefits of lower pressure

By reducing pressure drops, you may be able to operate your system reliably at a lower pressure. This offers several benefits:

- Lower power draw, as explained above.

- Less maintenance. Thanks to reduced demand, the compressor and motor won't have to work as hard. That means less wear and tear and lower maintenance expense.

- Reduced leakage. The lower the overall system pressure, the less air that can escape at leaks and unregulated users. This further unloads the compressor motor.

- Additional compressor capacity. Instead of wasting capacity on obstructions, capture the energy savings or use it productively to expand the system -- and possibly avoid buying an additional compressor.

Pressure drops can occur upstream or downstream of the compressor. Three strategies can eliminate downstream pressure drops in almost any plant.

Easier breathing

Buy larger filters for the air treatment systems. Filters remove particulates and oil from the airstream. Each size and model of filter has a rated flow for a defined pressure drop, usually 5 psid. As the filter clogs, the pressure drop increases — in many cases doubling to 10 psid. A simple way to keep pressure drop low is by changing dirty filters on a regular basis. An even more effective measure is to buy a bigger filter. Your best bet is to use a filter with a specification of 1 psid clean (2 psid dirty).

Using bigger filters offers two main benefits. A physically larger particulate filter doesn't need to be changed as often. And when it does get dirty, it introduces much less pressure drop — 2 psid instead of 10 psid. This simple strategy of using a sub-one psi pressure drop (or "sub-one") alone can save 3% on energy costs. The only capital cost involved is purchasing a larger filter casing. The ongoing replacement costs will be the same, or perhaps even a little less, because larger filters may not need to be replaced as often. See Table 1 for information on using standard catalog data to select filters with a 1 psi drop.

The "sub-one" criteria can be applied to separators, coalescing filters (which remove oil) and particulate filters. As an added bonus, most separators and coalescing filters work better with a slightly lower entering velocity. But be careful here; if the coalescing filter must handle widely varying flow, it can lose effectiveness below 25% to 30% of rated design.

Fatter conduits

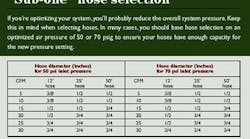

Focus on hoses and disconnects. An easy way to reduce pressure drop even more is by installing larger diameter hoses to get a larger cross section for airflow. Select hose size on the basis of flow rate. Table 2 provides recommended hose sizes for various air flows. It gives hose diameters as a function of inlet pressure that will result in a pressure drop of less than 1 psid for the specified hose length.

Consider upgrading quick disconnects. High-quality, properly sized units reduce leakage and allow unimpeded airflow. Size the disconnect to match the hose selected in Table 2 or 3.

Better terminal hardware

After installing filters with low insertion loss, examine the filter/regulator/lubricators. Any of the three components can cause a pressure drop. Upgrading the hardware improves performance.

Follow this suggestion for compressor filters: bigger filters are better. Although micron rating introduces some variation, the standard pressure drop most often used to specify a clean filter is 5 psid (10 psid dirty). Use a "sub-one" filter specification of less than 1 psid clean (2 psid dirty). If you also decrease the header pressure, consider increasing the filter size even more.

Ronald G. Wroblewski, P.E. is president of Productive Energy Solutions LLC, Madison, Wis. E-mail him at [email protected] or call (608) 232-1861.