Integrated compressor controls free the operator to make better air system decisions

"I don't understand. I attended the classes, both Fundamentals and Advanced. I read every article and book I could find on improving compressed air system efficiency. I developed great ideas about reducing compressed air consumption. We fixed leaks, changed piping, moved some processes to shifts that used less compressed air, bought low consumption nozzles and educated our entire workforce. We did this work and I still have six out of six compressors running nearly continuously. Reducing air consumption doesn't appear to have reduced air production."

This is not an uncommon lament. Major improvements to the demand side of a compressed air system often can fail to yield desired results on the supply side. Both halves of the system require action before energy costs start to drop. Additionally, future changes to either side will require the entire system be re-tuned. A good start is having a compressor service provider ensure that the compressor controls are set properly and the complete control system on each compressor is functioning properly.

After addressing demand side issues and tweaking the supply side to operate as it was intended, take the next step. Tie the supply side components into an integrated controller that can minimize run times, maximize savings, maintain a stable air pressure and provide constant data feedback for the whole system.

Historical perspective

Ten or 15 years ago, integrated controllers were priced from $25,000 to more than $50,000. The units required software written specifically for the individual application. Each air system modi-fication required rewriting the program. It was expensive, but it also was worthwhile for large systems.

The cost of a modern integrated controller has dropped considerably. High-tech electronics, experience and competition have resulted in controllers superior to previous generations and packed with more features. Payback in energy savings can be as little as a few months.

Cascading controls that required from 15 to 25 psig are obsolete and should be replaced. Contemporary integrated controllers can stabilize a properly designed system to within one or two psi. Controlling in a tight pressure band allows the compressors to operate at lower pressures, which saves energy. Remember, every two-psi reduction in compressor pressure yields a one-percent reduction in power consumption. Reducing system pressure also reduces air consumption at unregulated usersblow-off nozzles, leaks and the like. Use a simple orifice chart to estimate demand reduction.

Knowledge is power

Better information fosters better decisions, and controllers can provide that information. The features to look for in an integrated controller are listed below.

Remote monitoringSeveral controllers can act as Web servers. This allows operating personnel to connect the controller to the company intranet to monitor the air system from any computer having a Web browser. Many controllers have modems, as well, allowing monitoring from outside the facility.

Fully integrated air system components, not just the compressorsfilters, dryers and drainsneed to be monitored, too. Many are available with contacts to activate remote alarms. Pick a controller that allows ancillary components to be tied together. Problems in one part of the system may be the result of a failure of one of these components. Problem solving is much easier if sufficient information is readily available.

System status displayThese screens provide an at-a-glance view of system status and its service and alarm messages. Think of the system status display as the controller's home page that displays the operating status of each compressor and presents links to other related displays.

Message historyLook for controllers that include a message history display. Message histories are a system's black box that captures events as they occur. Knowing exactly what was happening right up to the moment of a sudden drop in pressure or the shutdown of some system component greatly simplifies troubleshooting.

System dataThis display gives operators a look at individual component settings and controller settings. If that's too much data to display on one screen, the controller should have links to supplementary screens that show system settings. Having settings easily available allows evaluating and changing control schemes to accommodate changes in either the system's supply or demand side. If production increases, a process moves to a different shift or a new compressor is installed, one can reevaluate the control scheme easily and make changes to optimize air system efficiency.

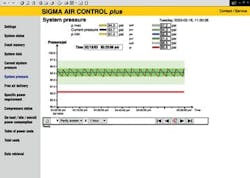

Some data is more easily understood if it's displayed as a graph. Examples include system pressure and a selectable history. Showing system pressure as a function of time can be a great benefit when trying to optimize supply side controls. Having real-time graphing, as well as the ability to pull up a day's worth, or a week's worth, or even a year's worth of data in a graphical format makes it easy to identify how changes to either side of the system affect pressure. Evaluating this data regularly also can help avoid production problems.

Another useful graph is compressor air deliveryindividual and aggregate, instantaneous and historical. As with the pressure, graphing airflow helps operators optimize the supply side. For example, if one compressor operates only briefly and shuts off for an extended period, compressor sequencing might need to be changed to have a smaller compressor handle that particular load. Another possible solution might be to add storage so the system can ride through the event without having to turn on a compressor at all. Operators will know this only if they have historical data. Seeing it in a graphical format is the easiest way to review system performance.

Graphing specific power consumption, current and historical, allows operators to shuffle sequences to make the most efficient machines run most of the time with the least efficient machines on standby.

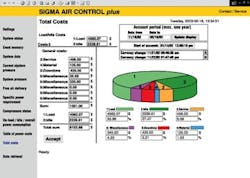

Overall operating costsBecause controller software monitors power and flow conditions, the next logical step is an analysis module that allows operators to track actual air system operating costs. If it's given the power costs, including seasonal or daily changes in power costs, the controller can calculate how much is spent for electricity to power the system. Improvements can be documented easily without having to resort to separate power meters for each compressor. Some controllers even allow operators to enter other maintenance costs and display the total air system cost in tabular and graphical formats.

Outbound callingAnother valuable feature on some of the latest controllers is a call-out function. Equipped with a modem, they can call or fax trouble messages to either plant maintenance personnel or the plant's service provider. Using a laptop computer and a phone line, the person notified can dial into the controller and monitor the entire system. This is especially useful in the middle of the night. The information provided to the service technician can support a decision to give it immediate attention versus waiting until morning. Remote troubleshooting also allows the service provider to gather the correct parts before arriving on site.

Better decisions

Fifteen years ago, compressor controllers consisted of a box with a few remote pressure switches, a timer or two and some lights to indicate that compressors were supposed to be running. If operators wanted more information, they had to go to each compressor and write down the temperature and pressure, the only data they could access.

Today's integrated controllers manage the compressed air system. As with any good manager, they also provide reports and data to help others make correct compressed air system decisions.

Wayne Perry is Kaeser compressor's Technical Director. He can be reached at [email protected] or 540-898-5500.

Figures: Kaeser Compressors, Inc.