Ask the Experts: Is a variable speed drive compressor right for you?

In this special feature, we pose some common compressed air questions to some of our Compressed Air Challenge expert instructors for feedback.

The Compressed Air Challenge is a voluntary collaboration of industrial end-users; manufacturers, distributors, and their associations; trade organizations; consultants; state research and development agencies; energy efficiency organizations; and utilities. The CAC has one purpose in mind; helping compressed air users enjoy the benefits of improved system performance.

The mission of the organization is to promote energy and operational efficiency in compressed air systems for industry through information and training, leading end users to adopt efficient practices and technologies while leveraging collaborative cooperation among key stakeholders.

To carry out the mission, CAC maintains a group of 20 highly qualified and experienced instructors who are available to deliver various product-neutral training offerings through in person or online training delivery.

Questions: My compressor vendor wants me to purchase a variable speed drive (VSD) compressor to make my system more efficient. Is this a good thing and why? Are there things I should watch out for that might cause me problems?

Greg Ashe (Kaeser Compressors, Denver, CO, L1&2 Trainer)

Variable speed compressors can reliably lower energy costs when applied correctly, but they may not be a perfect fit for all applications. If installed in a harsh environment or grossly oversized, repair and downtime costs can significantly outweigh potential energy savings. If you have moderate temperatures along with relatively clean and dry conditions in the compressor room, the next step would be to understand your compressed air demand and how it would benefit from a VSD compressor.

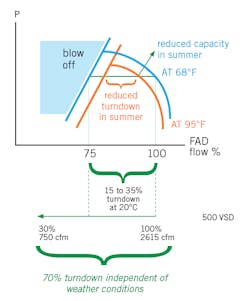

One large VSD compressor may seem attractive since it takes up less floor space and doesn’t require any master controls, but there are limitations on how much speed/flow it can vary. Many oil flooded compressors can turn down about 70% from peak flow, meaning there’s 30% where it can’t operate and has to shut down or unload. This 30% gap is referred to as a control gap, and if the compressor spends considerable time operating there, it may lead to long-term reliability issues. This is a frequent concern when a facility has very different flow requirements for shift #1 vs shift #2. For example, if you needed 1,000 CFM for shift #1 but only 200 CFM for shift #2, it might be better to have several small compressors working together instead of one large VSD. Multiple compressor systems can include a VSD, but many do not and may depend on other factors such as load sharing and serviceability of the system.

At the end of the day, equipment selection frequently comes down to budget and spending more capital on a VSD would require some type of justification, usually in the form of energy cost reduction. While compressed air consultants can provide recommendations to maximize equipment reliability and system performance, it’s difficult to accurately project energy savings from a VSD without first doing an air study or audit. Only after measuring the existing power consumption and flow can you then say that the new compressor X will reduce energy costs by 25% etc., assuming flow requirements don’t change.

Chris Beals (Denver CO, L1 Trainer):

VSD compressors will save energy if they are:

- Sized properly—In order to prevent a “control gap” the VSD compressor’s turndown range should be equal to or greater than the variation in demand or the capacity of the largest baseload compressor to be unloaded.

- Operated always as the trim compressor—At full load VSD compressors are less efficient than constant speed compressors so the constant speed compressors should be set to unload between the VSD compressor’s target pressure and its stop/unload pressure set point. Another option is to install compressor automation.

VSD compressors can prove unreliable if they are installed:

- Without sufficient storage—Insufficient storage can result in excessive hunting which can shorten the life of the capacitors in the Variable Frequency Drive (VFD). Hunting can be reduced by tuning the VSD compressor’s P&ID loop. In low demand situations rapid cycling of a start/stop VSD compressor can pump the lubricant out of the compressor.

- In a dirty environment, an area with excessive heat, or outside where the VFD is exposed to sun loading—The VFD control panel is fan cooled so a dirt buildup on the boards and capacitors and/or an environment with excessive heat reduce cooling; thereby, reducing the life of the VFD’s components.

Replacement motor and VFD availability can also reduce system reliability, due to supply chain disruptions it is not unheard of to see long delivery times exceeding 6 months for specialized items.

Frank Moskowitz (Phoenix, AZ):

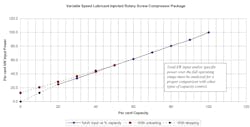

VSD compressors have some really nice benefits. The performance chart (Fig. 1) shows typical power versus capacity when using a variable speed compressor. This shows almost perfect power turn down with flow.

- The system is controlled by a pressure sensor mounted at the end of the air compressor package.

- This develops a 4-20 mA signal, which is first fed to the controls and compared to a setpoint.

- Depending on the signal, the communication is sent to the convertor to either increase or decrease the frequency to the electric motor.

- The VSD machine maintains the pressure within a band of about 2 psi and without pressure over-shoots.

- An example for bearings: Considering a fixed design constant C/P (bearing design constant) of 5000 for a bearing, for a fixed rpm of 2000, the bearing shows a lifetime of 50,000 hours. On the other hand, a machine running variable speed at an average 1000 rpm, the life of the bearing doubles.

Ron Marshall (Winnipeg, MB, L1&2 Trainer)

Few things in the compressed air industry have positively changed system performance as much as variable speed drive compressor technology. The key to saving energy in a system is the elimination of the unloaded run time that happens when a partly loaded system uses fixed speed compressors. Screw compressors use significant power when they run unloaded, VSD compressors do not. So, the use of a properly sized VSD compressor in a system of one compressor, or with multiple fixed speed compressors can save lots of energy, typically averaging 20% to 30% over fixed speed drives.

VSD compressors also provide a more constant and stable air pressure output, allowing system pressure to be reduced, saving about one percent power for every two psi in average pressure reduction. As the pressure reduces, many of the unregulated compressed air consumers in the plant will use less air, about 1% less per one psi reduced. This reduces compressor power even more.

And due to the almost perfect turn down relationship between power and flow, if you are diligent in doing frequent leakage repair and eliminating other wasteful compressed air demands, having VSD control will save the most money, the efficiency of this technology unlocks extra savings for demand reduction.

But heed the warnings already mentioned by previous experts, VSD compressors do not perform well in hot, humid, dusty environments, so keep them clean and cool. And be sure to have a compressed air assessment done on your system to make sure the equipment you are purchasing will be properly sized for your application. It is not good to oversize a VSD and have it run constantly in its minimum speed range.

Check all these boxes and you could have a well managed VSD controlled system that saves you money, year after year.

This story originally appeared in the November/December 2022 issue of Plant Services. Subscribe to Plant Services here.