6 common design mistakes in compressed air systems

Compressed air systems are always essential parts of industrial plants, and we need to ensure they are well designed and will run efficiently. Compressed air auditing professionals frequently come across many common design mistakes made in installing this essential but inherently inefficient plant utility. This article discusses some of these nagging problems with some suggestions in how to avoid these costly design mistakes.

1. Compressors are too large

Frequently the compressors purchased for a new facility will be too large, causing them to run very inefficiently. This is particularly problematic when only one compressor is purchased, putting all our eggs in one basket, and that unit is a variable speed drive (VSD) compressor.

Why does this happen? Well very few designers will get fired for sizing a compressor too large; however, if the compressors are too small, and the new installation can’t make pressure, then serious trouble results. To avoid this situation design factors are added for safety, often making the compressor capacity larger than needed.

There will always be an element of doubt as to the final make-up of the compressed air demand. Design factors will be applied to account for future growth, unexpected load additions, and future flow due to leakage. By the time this process is done the final compressor size can end up being twice what is actually needed.

Oversized compressors consume significantly more energy than required, and energy is the biggest part of the overall compressor life cycle cost, often accounting for more than 90% of the 15-year total. Oversized VSD compressors that run at light loads are particularly problematic if they end up running below minimum speed, a condition that can allow condensed water to build up in the compressor lubricant, risking compressor damage.

Tip: This problem can be minimized by installing a system of multiple smaller compressors rather than one or two larger ones (see Figure 1).

2. VSD compressor is too small

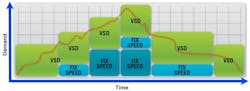

One of the best ways to save energy in a compressed air system with wide flow variation, like a shift-oriented plant, is to use a VSD controlled compressor in the mix with one or more fixed speed compressors; however, it is common to see the size of the variable compressor too small for efficient control.

It is human nature to want symmetry, so when a system uses, for example, two 100 hp fixed speed compressors, we naturally want to install a similar sized 100 hp VSD compressor. However, this would be a mistake and would create a “control gap” in system capacity within which the variable compressor would fight for control against one or more fixed speed compressors (see Figure 2).

Tip: To avoid control gap the variable range of the VSD compressor must be equal to or larger than the largest fixed speed compressor with which it must work. This usually means purchasing the VSD of the next size larger at minimum.

3. Inadequate main storage receiver size

Very often system auditors run across installations with no main system storage, or with a very small storage receiver size of about one gallon per cfm compressor capacity. When this happens, the compressors will rapid cycle and often be out of control because the pressure is changing too quickly to maintain stability. Designing in properly sized system storage will slow pressure fluctuations down and allow efficient and orderly compressor control.

Tip: Storage receiver sizing of 1 gallon per cfm is “old school.” System designers have since realized a well-controlled system needs about 3-5 gallons per cfm storage capacity, and best-in-class systems have upwards to 10 gallons per cfm. So, for example, if a system has two 300-cfm compressors, and a one 460-cfm compressor, we would want between 1,380 and 2,300 gallons of total system storage receiver capacity. Best in class would have 4,600 gallons of storage divided between wet and dry receivers.

4. No planning for failure

Once you’ve designed in some nice efficient compressors and properly sized the system, you’ll need to take time to plan for future failure. Those compressors will not stay new forever, and there will be times where they will fail or need maintenance. If you want to ensure the failure is not a disaster, you will need to design in some backup capacity.

Tips: It is best to ensure pressure reliability by making sure you have at least enough backup capacity to ride out the failure of your largest compressor and still be able to maintain the pressure during system peaks. And be sure to design in well-located service ports so that rental compressors can be installed if the worst happens. These service ports should be located before system air dryers to ensure good air quality even when hot and wet diesel driven compressors with inadequate after-coolers are used.

5. Piping is too small and/or is in the wrong layout

System designers always have a tradeoff to consider between the cost of the main system piping and the size installed. Very often, no calculations will have been done in determining the pressure drop across system piping, and size will be decided by the piping contractor. The size therefore often ends up being the diameter of the discharge port on the compressor resulting in excessive pressure differentials.

Best-in-class systems ensure the air velocities within the main system piping at the chosen operating pressure are always between 20 to 30 feet per second for compressor room header piping, and between 30 and 40 feet per second for main plant distribution piping (see Figure 3). Always consider arranging the plant piping in a loop or multiple loop system to reduce the pressure loss. Pressure drop in piping varies with the square of the flow changes, so a parallel feed of pipe will have one quarter the pressure loss compared to a single pipe of the same size.

Tips: Be aware that there will be times in the future where the air drying system will fail, so slope the piping carefully away from the direction of flow and install drains at all low spots. Ensure all entrances and exits from main distribution are from the top of the pipe to ensure the best air quality, should moisture be present in times of failure. Using this sizing advice, your system should have a total pressure loss (not including dryers and filters) of less that 2% of the system pressure. So, for a 100-psi system, the pressure loss in the main distribution system end-to-end should be less than 2 psi.

6. Purchasing cheap and inefficient components

Designers should be aware that the energy consumption of a compressed air system is by far the largest life cycle cost of running the system. For this reason, premium efficiency compressors, air dryers, filters, and condensate drains should always be considered with an eye to the total cost of operation, not just the purchase price.

Tip: Don’t forget about system components supplying and conditioning the air at the end uses of a compressed air system. Very often poor design at this location can cause local pressure loss of 15 to 20 psi through under sizing. These items should be always selected for peak flow of each individual compressed air demand, not the average. Careful component selection at this location can go a long way in reducing the required system pressure, while reducing the cost of system operation.

About the Author

Ron Marshall

Ron Marshall first developed his skills as an industrial compressed air systems expert at Manitoba Hydro, where he worked for 38 years, supporting more than 600 energy efficiency projects. He now operates his own compressed air energy efficiency consulting firm where he provides technical advice, system auditing, and training. Ron is a level 2 instructor with Compressed Air Challenge and conducts training internationally. Contact him at [email protected].Want to learn more about compressed air? We would suggest sending key staff to one of our Compressed Air Challenge seminars to help them learn what is possible. To learn more about upcoming training opportunities visit the CAC calendar at https://www.compressedairchallenge.org/calendar.