8 ways to justify upgrades to your compressed air system

For more than two decades of my career working with an energy utility in support of energy efficiency programs, I had many chances to experience the decision-making process when it comes to justifying the replacement of compressed air equipment. We had millions of dollars of energy incentives available (many of my customers called these funds “free money,” which we used to help persuade our customers to make their systems more efficient).

Early in my career I made a stunning observation. I found most of my customers did not view compressed air energy efficiency as their primary concern; in fact, many plant managers would willingly spend three or four times more on energy if only their systems would work properly.

This fact kind of hurt my feelings, until I realized that my recommended upgrades could often both fix the biggest and most important compressed air problems and make the systems more efficient—a double win. The energy savings came on the coattails of fixing larger, more important issues. Once I figured that out, our compressed air program reach exploded.

When delivering Compressed Air Challenge’s Fundamentals of Compressed Air Systems seminars, we instructors always start off explaining the main purpose of the training, which is to help you improve the performance of your compressed air system. I always point out that this statement doesn’t specifically say “improve efficiency” because there are far more important benefits to performance improvement.

This article discusses some additional ways to justify compressed air system improvement, many of which do not necessarily have direct energy efficiency benefits.

1. Maintenance and repair costs

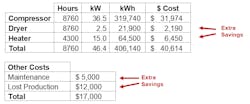

One of the first things I ask for when doing compressed air systems assessments is the maintenance and repair costs over the last few years. This is often overlooked when outsiders come into a plant to do compressed air audits, but this information is very easy to obtain from the plant maintenance tracking software (see Figure 1).

Older or inefficient compressed air systems often require more frequent maintenance and repairs. Upgrading to newer equipment will often significantly reduce the need for costly repairs, spare parts, and maintenance services, resulting in significant cost savings over time.

An example of exploring costs is at a large paper mill. The system had four ancient 1960s vintage 200 hp lubricant free reciprocating compressors running continuously (see Figure 2). These units were far past their useful lifespans but were repaired and rebuilt regularly rather than being replaced. Upgrading these to newer technology screw type compressors would have saved about 5% in energy consumption, which is not a strong argument for change; however, once we pulled the maintenance records, we found that the average annual repair costs far exceeded the energy costs of the machines. This made justification for replacement much easier.

2. Cooling and heating costs

These important costs often come into play with liquid-cooled compressors when the cooling water comes at a cost. For water-cooled compressors using city water and dumping the spent water into the sewer, the resulting water meter charges can very easily exceed the cost of the electricity. A switch to an air-cooled compressor style during an upgrade may avoid future extra costs. If impossible, the use of manufacturer-supplied heat recovery systems may allow you to take the heat out of the cooling water and use it in a process in your plant.

For air-cooled compressors in dusty environments using 100% outside ventilation air, the compressor room must be heated to avoid freezing the compressor coolers. Fuel costs add up and can be used to justify upgrading compressor room heat recovery ventilation that might redirect and recycle compressor heat to avoid excessive heating costs.

3. Reliability

Older compressed air systems are more prone to unexpected failures and breakdowns, which can result in costly production losses. Upgrading to a newer, more reliable system often comes with improved monitoring and predictive maintenance capabilities onboard that are built into the machine controls to help reduce the risk of unplanned downtime and associated financial losses.

When performing a compressed air assessment at a distillery bottling facility, the subject of reliability was discussed with the production manager. He whipped out his trusty calculator and did some quick figuring. He showed his result on the display, which said $120,000. His product was a premium offering and every bottle shipped was quickly sold. He explained that the company lost that amount in sales for every hour his production line was down (see Figure 3). For this customer, system reliability was the most important part of his compressed air system operation.

4. Increased capacity/backup

Upgrading provides an opportunity to reassess and optimize the sizing of the compressed air system. Often, because of production equipment additions and increased flow due to leakage and inappropriate compressed air use, the compressed air demand will reach or exceed the total capacity of the existing compressors. When this happens low pressure events will occur, often coming out of nowhere at the most inopportune moments in the production cycle.

The bottling plant in the previous example was one such case; when any of its compressors went down due to failure or emergency maintenance, the production equipment stopped for hours until diesel backup compressors could be brought in. Profits were affected by the production downtime and took a hit due to the costly rental and fuel costs of the diesel backup units.

In this case it would only take one outage to justify the cost of purchasing backup capacity. For any compressed air system, the available capacity should always be at least enough to account for the failure of the largest installed compressor. Regular system audits are recommended to ensure you have enough capacity.

5. Air quality

Water and compressor lubricant may be pouring out of your compressed air system pipes and receivers and affecting your product quality (see Figure 4). Upgrading the compressed air system can enhance air filtration and purification capabilities. This ensures that the produced air meets the required quality standards, reducing the risk of product contamination or rejection. By avoiding product quality issues and associated costs, upgrading the system can deliver cost savings in terms of product waste and rework.

One potato products company learned a hard lesson a few years ago about compressed air system design and compressor selection. Within its production process the compressed air contacted the product, so it was important to keep the air the air clean, dry, and free of lubricant. The compressors it installed were a lubricated screw design, a type where compressed air comes in contact with compressor lubricant during the compression process. Normally the lubricant is filtered out of the compressed air output by an air/oil separator, but unfortunately there was a complete failure of the separator filtration element, which released many gallons of compressor lubricant downstream to overwhelm filters and contaminate piping. The cleanup costs and lost production in this case consumed many thousands of dollars in profits. Had the plant upgraded to lubricant-free compressors, these costs would have been avoided—in hindsight a good decision years ago could have avoided a costly cleanup.

6. Pressure stability

Depending on the type of compressor control installed in your plant, you may be experiencing large swings in air pressure, which could be affecting your production. Compressed air is an energy source and a change in pressure often varies the force and speed of pressure sensitive devices or may even cause machines to fail completely due to low pressure cutout.

In an extreme case, a foundry was experiencing compressor control problems leading to pressure fluctuations that affected the way its product was poured. Quick fluctuations in pressure would cause casting defects, resulting in product rejection in final quality inspection. The problem was that it took four days between the pouring operation and the final test. Fluctuating air pressure was very costly in this case.

Had the system been upgraded to newer VSD technology and good compressor control strategy employed, this company could have avoided many thousands of dollars of lost product caused by pressure instability. Taking this loss into account makes for easy justification of better technology.

7. Utility incentives

Depending on your location and electricity supplier, there might be energy incentives, grants, or rebate programs available to help you upgrade to energy-efficient compressed air systems. Exploring these opportunities can provide additional cost savings and financial support for the upgrade.

Very often the energy incentives are substantial, sometimes providing support as high as 50% of the total cost of the upgrade. This becomes very important in old systems where the compressor units have to be replaced anyway due to age. When you consider this work has to be done, the actual incremental cost of any upgrade reduces substantially. Always be on the lookout for utility incentives to help justify improvement projects.

8. Energy efficiency

Times have changed in the compressed air industry and equipment manufacturers have responded. Air compressor energy efficiency has significantly increased through better design and control, and the efficiency of ancillary components such as air dryers, filters, and drains have all improved significantly. Upgrading your system may result in substantial energy savings, which can help a lot in justifying new equipment.

How do you know if your system is up to snuff? Well, it needs to be measured. If you don’t have a good permanently installed system of measurement, you should call in a competent auditor to do an assessment. The auditor will assess system operation and let you know if any improvements are needed and how much you could save.

Costs and potential savings

When justifying a compressed air system upgrade, it's important to consider these additional potential cost savings areas in conjunction with current and future energy costs. You can use these often-overlooked areas to demonstrate a comprehensive financial case for any future investments.

Want to learn more about compressed air so you can better understand what to do to make your improvements? I would suggest attending a Compressed Air Challenge seminar to help learn what is possible. To learn more about upcoming training opportunities, visit the CAC calendar at https://www.compressedairchallenge.org/calendar