Systematically improve your transformer reliability

Wesley Suplit, project manager for SDMeyers, is responsible for transforming ideas into products, services and customer experiences related to improving the reliability of electrical equipment and decreasing failure modes. During the webinar “Electrical systems: Tips for systematic improvement of transformer reliability,” Suplit answered attendee questions on how to better improve transformer monitoring and reliability.

PS: What kinds of monitoring are utilities performing? And if I'm not working for a utility, how would my strategy be similar or different?

WS: What is important to understand here is that the needs of a utility are very different from the needs of an industrial location. We see this very stark contrast. A utility, for example, has thousands of transformers, and that asset class in their mind is the primary driver for revenue. That is how they distribute the electricity to all their users.

They apply testing and monitoring in a way that is extremely generous, meaning they might have an entire fleet of transformers with what I've called “check-engine lights” and/or single gas monitoring, as well as critical pieces of equipment with the full system, an integrated system, and they have a liberal application of this.

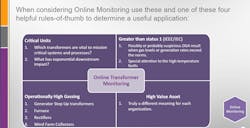

The different needs come from not differences in type, but differences in degree. We would see industrial locations typically picking two or three highly critical units that control the inflowing power, and they would choose to monitor those units. We would call those sub-transmission transformers coming right off the transmission grid. Those would be kind of that key to the rest of the power system.

PS: How do I better communicate the impact of online monitoring to my boss or team leader? What is the one thing which you would recommend when it comes to communicating the impact?

WS: If you're going to keep it simple, I would say, show how an online monitor not only can reliably extend the life of the transformer, but maintain the current state of reliability without an unplanned outage. One of the keys of reliability is to understand the impacts of an unplanned outage. Understanding this for yourself is that first step; once you understand it for yourself, you can effectively communicate it around your organization.