Putting your cables to the test: Getting the most from your MV cables

Medium-voltage (MV) cables are a vital component of your plant’s electrical power distribution system. Although their service life is expected to be long and they are generally highly reliable, MV cable systems can and do suffer from deterioration, defects, and faults, which can eventually result in complete breakdown and cable failure. Such failures can, in turn, lead to unplanned power outages, causing substantial losses including loss of plant production, significant equipment damage, and even personnel injury or death.

To protect people, operations, and the bottom line, you need insight into the condition of your MV cable systems. Fortunately, there are several tests and techniques that can help you keep a finger on the pulse of the health, performance, and reliability of these systems. However, choosing the right tests from myriad available options isn’t always a straightforward process. Let’s consider some of the more-popular testing options for MV cables and explore which test methods are best for a given installation or specific testing philosophy.

Industry standards: a great place to start

When it comes to selecting the best MV cable system tests for a particular facility or application, many plant managers turn to industry standards. In the United States, there are at least 10 standards that provide information about field testing MV cable and components. Among these are standards from the Institute of Electrical and Electronics Engineers (IEEE), the National Electrical Manufacturers Association/Insulated Cable Engineers Association (NEMA/ICEA), the Association of Edison Illuminating Companies (AEIC), National Fire Protection Association (NFPA), and the InterNational Electrical Testing Association (NETA).

These standards are continually being reviewed and updated, and they provide a good overview of the types of tests available. However, when choosing the best tests for your specific situation, you’ll want to consider the age and general condition of your cable system as well as the service level (loading/load cycles), operating environment, history, and criticality of equipment served. We’ll now take a closer look at each of these issues, beginning with understanding the lifespan of your MV cable system.

Understanding cable life

In general, an MV cable system is expected to provide reliable service for approximately 35 to 40 years. However, cable system components (conductor, insulation, shields, jacket, etc.) can be damaged mechanically during shipping, handling, or installation or by or other physical means such as excavation, settling of the earth, or support failure. Additionally, operational damage can occur due to severe load cycling, overloads, short-circuit currents, voltage transients, and lightning surges. The environment in which the cable operates also has a significant impact on lifespan. Exposure to extreme temperatures, moisture, heavy vibration, or chemicals can contribute to premature deterioration and/or failure.

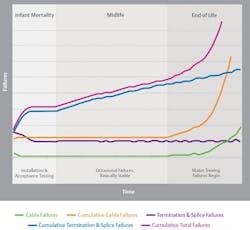

Regardless of specific stressors, cable systems experience periods within their life cycle during which failure is more predominant. The first year of a cable’s operating life is considered the “infant mortality” period. If installation damage or manufacturing defects are not detected during initial acceptance testing, these problems will likely show up during this time.

Between initial operation and end of life, cable systems go through a period of relatively high reliability. Occasional failures may occur as a result of workmanship issues or uncontrolled factors, but in general, the cable system will exhibit its highest reliability during this period.

After a long period of reliable service, operational and environmental factors will lead to deterioration of cable components, creating an increased rate of failure. This is an indication that the cable system is approaching the end of its reliable life.

Different tests are recommended during different life-cycle periods. Here’s a look at the different types of cable tests and when to use them.

Types of MV cable testing

In general, there are two types of cable testing. Withstand tests are intended to stress the cable’s insulation and cause the cable system to fail at defects or areas of significant deterioration that could likely cause the cable to fail in the near future during normal operation. Condition assessment or diagnostic tests produce quantitative and trending data without causing (or intending to cause) failure or damage. These tests are used to determine the extent of deterioration or changes to the cable’s insulation system. Both types of tests play an important role in evaluating the reliability of the cable and determining if the cable is reaching the end of its life. Following is a closer look at the specific types of test within each category.

Withstand tests include:

- DC high-potential (hipot) withstand: a go/no-go test that puts cables under higher-than-normal operating voltage stress to identify weaknesses and cause them to fail. This test is not recommended for cables more than five years old. Research suggests that this test is not the best test for extruded insulated cables, as it is not effective in locating many defects that could lead to premature failure of a cable system.

- AC hipot withstand: another potentially destructive go/no-go test that is similar to the DC test, but this one utilizes AC voltage. Although this test is an improvement over DC hipot, the test equipment needed to handle the higher-than-normal operating voltage can be large, heavy and expensive.

- Very-low frequency (VLF) hipot: a test for effectively detecting various defects in a cable system. It has recently gained popularity because the equipment is small and lightweight and is relatively easy to use. While this test is considered a destructive test, the recommended test voltages are much lower than the DC test voltages and, when coupled with condition assessment tests (discussed later), the chances of causing damage to the cable system can be reduced.

Condition assessment/diagnostic tests include:

- Tan delta: a diagnostic tool that measures the level of cable deterioration and can help determine service reliability. Tan delta testing is useful for prioritizing cable replacement and is particularly useful in determining whether cable is approaching the end of its life. Tan delta testing is effective in detecting water trees, a key indicator of aging in extruded insulated cables.

- Online partial discharge (OLPD): noninvasive testing that can be conducted during operating hours and under normal operating conditions with no need to interrupt service and production. These tests assess the condition of cable systems (including splices and terminations) as well as connected equipment such as transformers and switchgear. Partial discharge (PD) is a key indicator of impending insulation failure in extruded insulated cables. Because insulation breakdown is the leading cause of electrical failure, according to NFPA 70B, monitoring PD activity plays a crucial role in preventing unplanned outages.

Annual or semiannual OLPD testing is recommended for MV cable systems to detect early signs of insulation failure. This allows for planned shutdowns to investigate and remediate issues before they have a chance to develop into a major problem.

Some plant managers choose to permanently mount sensors for hard-to-access areas or areas that pose a safety concern. These sensors provide connection points for portable equipment, which allows for periodic testing. Sensors can also be connected to continuous monitoring distributed control systems (DCSs) that trigger alarms when changes in PD levels are detected.

Testing philosophies: Not if your cables will fail, but when

While the reliable operating life of some equipment can be extended by rebuilding, reconditioning, or retrofitting, MV cables are life-limited components that will eventually deteriorate and fail. Therefore, tests must be conducted throughout the cable’s lifespan to help plant managers determine the condition of their cable systems and reduce the risk of failures. The choice of which tests to use should be based on where the cable is in its life cycle and the criticality of the load. In a nutshell, the right test (or combination of tests) often comes down to a decision based on risk management.

Before diving into how to develop your own customized testing philosophy, it’s worth addressing one common question: Can these tests tell me the remaining service life of my cables? Very simply, the answer is no. What these tests do reveal are indicators of defects that will likely cause your cable to fail in the near future (withstand tests). They will also tell you if your cables exhibit test values typically found in cables that are at high risk of in-service failure, or if they exhibit test values associated with cables reaching end of life.

Determining which test is best

With newly installed cables, your primary concern should be making sure they are installed correctly and that there are no incipient defects or problems. This is an ideal time to perform withstand tests. As mentioned earlier, these tests are great at forcing defects and failures because of the increased stresses imposed on the cable insulation system. Identified problems can be repaired and faulty equipment can be replaced before going live. This stage is also the best time to obtain baseline test values for condition assessment tests. Tan delta and OLPD testing are ideal condition assessment tests to establish baselines and detect any installation or equipment issues that may exist.

The next ideal time to perform testing is approximately one year after installation or just before your equipment or installer warranty expires. Withstand tests should again be considered to detect any incipient defects. Repeating the condition assessment tests and comparing results with the original baseline values is also a good practice. Any significant change should be investigated.

After cables have been in service for a few years, the same tests should be repeated. Withstand tests coupled with condition assessment tests should be performed to detect both hidden defects and early signs of aging.

To determine how often to test, a few factors should be considered, such as the availability of an alternate feed that can be utilized if a set of cables fails and the criticality of the load served by a given set of cables. You should also ask yourself, if a cable or termination/splice fails, will the collateral damage likely impact the alternate feed equipment, resulting in an unacceptable outage period?

As cables age, the destructive nature of withstand testing is a less-suitable testing option. This is typically because cables are a critical component and alternative feeds or options don’t exist. However, if you don’t perform these tests, you may be missing defects that, if not detected by condition assessment tests, could result in an unplanned outage and collateral damage.

One recommended testing strategy is to perform condition assessment testing such as tan delta before conducting a withstand test such as VLF. By performing the tan delta test first, you are able to evaluate the overall condition of the cable. If problems are indicated, don’t perform the VLF withstand test. If the tan delta test results compare closely with previous results and are considered normal, then the VLF withstand test can be performed because it poses less risk of causing cable failure.

This testing philosophy was put into practice with one facility that contained aging cables. The maintenance manager needed to provide management with evidence justifying the need for cable replacement. However, he couldn’t afford to damage cables during testing. Tan delta testing provided the solution. These nondestructive tests identified significant deviations in two sets of cables without applying voltages that could further damage aged cables of unknown condition. The circuits in question were located underground beneath an area of heavy equipment traffic. The resulting vibration from the traffic, combined with a possible bus duct collapse, likely contributed to the deterioration/damage of these cables.

In another example, elevated PD of two circuits was identified through OLPD testing. Because the PD was identified as having been generated from within the cable circuit (not the connected equipment or terminations), additional testing to determine the exact location of the PD was performed. A cable mapping process revealed that the sources of the PD were approximately 1,030 feet down the length of the 1,220-foot cable circuit. Scouting out the location revealed a manhole where the cable supports had failed and the cables experienced excessive bends. This severely deformed the cables, causing insulation damage and creating the PD. Visual inspection also revealed signs of overheating in the area of the excessive bends.

By replacing the damaged cable section, splicing cables, and adding proper cable support, the plant manager was able to prevent imminent failure, which would have disrupted other cables in the manhole and caused a disruption to production.

Depending on the variables previously discussed, a common test frequency during the midlife period of a cable is every three to five years. If cables are extremely critical, lack alternative feeds, or show signs of possible issues (via test results), testing may be performed more often. Cables that show high reliability based on test results and those that have alternative feeds may be tested less often.

One stopgap test that provides supplemental data to the VLF withstand and tan delta condition assessment tests is the OLPD test. Because this test can be performed without an outage and does not require that equipment be disconnected, periodic tests to identify changes in PD activity in the cable or associated equipment can be very valuable. Equipment also exists that allows your cables and associated equipment to be monitored continuously so that you can be made aware immediately of any changes in PD activity and begin an investigation process.

End of cable life

Just as humans age differently, so do cables. Various environmental factors, along with operational stresses, contribute to the aging and deterioration of your cables. If your cables are approaching the end of their life, you have likely witnessed changes in your condition assessment test results indicating water migration and insulation and shield deterioration. It is during this stage that you should increase the frequency of testing and avoid withstand tests altogether, or you may perform a modified withstand test that puts less stress on the cables. OLPD testing should be continued, as it is nondestructive and is effective at detecting deterioration of splices and terminations.

Steve Park, PE, USAF (Ret.), is technical services manager for the Electrical Reliability Services group at Emerson Network Power (www.emersonnetworkpower.com), overseeing such offerings as power system studies and conformity assessment services. Park is also responsible for evaluating and supporting new test technologies.

Once your condition assessment test values have increased to a concerning level, you should begin a capital replacement program. If you have monitored and tested your cables over their life, you can justify the need for replacement based on the historical test results. Not all cables will age at the same rate, so not all of your cables must be replaced at one time. Cable replacement can be prioritized based on criticality of loads served, alternative feed options, and historical test results. The replacement program can be spread over many years.

Clearly, MV cable testing plays a critical role in determining the health of your electrical assets and ensuring maximum uptime. When you understand your testing options and establish a testing philosophy that meets your specific needs, you can create a testing program that combines the right type of tests at the right intervals. These tests will provide you valuable information about the condition of your cables and help you avoid unplanned outages, prioritize your maintenance budget, justify requests for cable replacement, and keep your plant operating safely and reliably.