Change management to change the electrical safety culture in your plant

In brief:

- Electrical safety starts with being well-trained, knowledgeable, and informed, essentially “qualified” to perform the work.

- Unsafe work habits must change by anticipating the unexpected and making plans, prior to conditions changing, in order for the work to be performed and completed as safely as possible.

- In resolving the issues in analyzing electrical hazards in an industry, we must follow a path that will lead to a comprehensive analysis of the problems that exist and provide appropriate PPE and clothing.

Figure 1. It’s the responsibility of all employees to protect themselves and their jobs

The need for analyzing electrical hazards in the workplace has been recognized by a small segment of the industry for many years. The petrochemical industry and many government institutions have performed research on this subject for more than 40 years. For the most part, however, the user level of the electrical industry has largely ignored the subject, essentially reacting to catastrophic accidents and equipment failure rather than proactively trying to predict and prevent them. The arc flash incident that completely destroyed the front of the electrician’s shirt, along with severely burning the electrician, could have been prevented if management and the worker completely understood the electrical maintenance hazards.

Leaders should understand that an important portion of the business process, if it were to fail, could not only injure or kill employees, but also could shut the business down for days. If you have tasks in which you have this kind of exposure, shouldn’t you be involved in the decision-making process to make electrical maintenance and operations safe? Hazard risk assessment makes good business sense. It’s the responsibility of all employees to protect themselves and their jobs (Figure 1).

Electrical safety starts with being well-trained, knowledgeable, and informed, essentially “qualified” to perform the work. Remember, being informed and knowledgeable in electrical safety must happen at all levels. Every person who performs electrical maintenance and every supervisor or manager who is involved with maintenance technicians or is associated with the maintenance department must be informed and be able to engage in risk assessment. Safety practices alone cannot protect the electrical worker; it must be ingrained into our business culture as a principal.

How do we go about changing the culture?

Maintenance technicians pride themselves on being able to repair anything, anytime, anywhere, regardless of the hazards associated with the electrical work. Unsafe work habits must change by anticipating the unexpected and making plans, prior to conditions changing, in order for the work to be performed and completed as safely as possible.

Figure 2. Proper training is one of the most important elements of changing work habits to avoid any surprise when conditions change.

Proper training is one of the most important elements of changing work habits (Figure 2). We must never be surprised when conditions change; we should be prepared for the potential “what ifs.”

Before you act, take into consideration what the obvious and known hazards are. Check if there are any hidden hazards or any potential for dangers associated with the work that is about to be performed. If there are potential dangers, what could possibly go wrong, and is there a safer way to do the job? And, before the job begins, make certain that the workers are fully prepared to proceed safely.

Most electrical workers don’t view themselves as at risk of injury or death when performing tasks on energized equipment. The reason why is because they have developed poor work habits over time. They have become comfortable with the shortcuts they take on a daily basis, and they have lost all perception of risk.

In fact, the risk/danger never changed at all. Do you look at a job and think there’s a 20% chance that a worker will get severely hurt or killed if they perform this task? If you did, why would you have the electrical technician continue the task?

Safety factors

Electrical technicians and managers need to understand what is necessary to do the electrical work safely as opposed to the “why you can’t do this” stigma that is attached to electrical safety. They also need to understand the possible injuries associated with electrical hazards in order to enable safe choices of how to perform the work, and electrical technicians need to develop good work habits. If leadership is not trained to recognize unsafe work practices, the unsafe work practices will continue until there is an incident.

Each year several hundred workers are killed as a result of inadvertent contact with energized conductors. Surprisingly, more than half of those killed are not in traditionally electrical fields, but are workers from related fields, such as painters, laborers, and drivers. Recent investigations into the causes of these fatalities point to three principal causal factors:

- failure to properly or completely de-energize systems prior to maintenance or repair work

- intentionally working on energized equipment

- improper or inadequate grounding of electrical system components.

The three factors form the basis for analysis of the electrical shock hazard.

To appropriately assess the electrical shock hazard associated with any type of maintenance or repair work, it is necessary to evaluate the procedures or work practices that will be involved. These practices should be evaluated against regulatory requirements, national consensus standards, and recognized safe work practices within the industry.

Regulatory requirements and best practices

Figure 3. When energized work is performed, the energized work must be performed in accordance with electrical safety standards, regulations, and written procedures.

All equipment must be placed in a de-energized state (electrically safe work condition) prior to any maintenance or repair work (limited exceptions exist). The de-energized state must be verified prior to any work. The de-energized state must be maintained through the consistent use of locks and tags and, in some cases, temporary protective grounding. When energized work is performed, the energized work must be performed in accordance with electrical safety standards, regulations, and written procedures, including an energized electrical work permit (Figure 3).

Plan every job. Anticipate unexpected results and the required action for these results. Use procedures as job aids. Identify the hazards, keep unqualified workers away from these hazards, and assess employees’ abilities. In addition to the assessment of work practices, a shock hazard analysis must include an assessment of the physical condition of the electrical equipment and system. Although the continuity and low resistance of the equipment grounding system is a major concern for reducing the risk of electrical shock, it is not the only one. Of equal importance is ensuring that covers and guards are all in place, that access to exposed conductors is limited to electrically qualified personnel, and that the overcurrent protective devices are well-maintained and of appropriate interrupting rating. Even the safest procedures, when performed on poorly constructed or maintained equipment, don’t protect employees.

Arc flash hazard analysis

An estimated 75-80% of all serious electrical injures are related to electrical arcs created during short circuits, ground faults, and switching procedures. In recognition of this fact, standards organizations such as the National Fire Protection Association (NFPA) and the Institute of Electrical and Electronics Engineers (IEEE) have provided the industry with techniques to evaluate the magnitude of the electrical arc flash hazard and recommend appropriate protective clothing and equipment.

The principal factors used to determine the arc flash hazard are:

- available short circuit current at the arc location

- duration of the electrical arc

- distance from the arc to personnel

- arc gap.

To accurately assess the arc flash hazard and make appropriate decisions regarding personal protective clothing and equipment, it’s necessary to understand fully the operation of the system under fault conditions. This requires both a short-circuit analysis and a protective device coordination study. It’s a common misconception that arc flash hazards are an effect of only high-voltage. The actual arc flash hazard is based on available energy, not available voltage. In certain conditions, a low-voltage arc’s duration is longer than that of a high-voltage arc. With this information available, the magnitude of the arc flash hazard at each work location can be assessed using several techniques. These techniques include:

- NFPA 70E, “Standard for Electrical Safety in the Workplace”

- IEEE Standard 1584, “IEEE Guide for Performing Arc-Flash Hazard Calculations.”

Each of these techniques requires an understanding of anticipated fault conditions and the limitation of the calculation method. The results of the arc flash hazard analysis are most useful when they are expressed in terms of the incident energy received by exposed personnel. Incident energy is commonly expressed in terms of calories per cm2 (cal/cm2). Arc protective clothing is rated in terms of its arc thermal performance value (ATPV), also expressed as cal/cm2. In addition to protective clothing, there are some safe work practices that can be adopted to minimize or eliminate the hazards. These practices include clothing, body positioning, and insulated tools. Line clearance procedures and other factors must be carefully scrutinized to ensure the risk to employees is minimized.

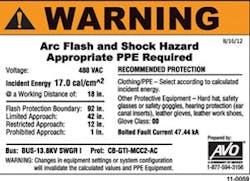

National Electrical Code Section 110.16 Arc-Flash Hazard Warning states, “Electrical equipment, such as switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers, that are in other than dwelling units, and are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked to warn qualified persons of potential electric arc flash hazards. The marking shall be located so as to be clearly visible to qualified persons before examination, adjustment, servicing, or maintenance of the equipment.” Because of the NEC requirements, we can conclude the easiest and most effective way to mitigate the arc hazard is to de-energize the system completely for any type of maintenance activity.

Arc blast hazard analysis

Figure 4. Most employers, operators, and electricians are knowledgeable in the selection and inspection requirements for electrical PPE used for the prevention of electrical shock hazards, as well as head, eye, hand, and foot protective equipment.

An electrical blast is the result of the heating effects of electrical current and the ensuing arc. This phenomenon occurs in nature as thunder that accompanies lightning, a natural form of an electrical arc. Unfortunately, little can be done to mitigate the blast hazard, at least in terms of personal protective clothing. Blast pressure calculations can be used to determine whether enclosures will withstand an internal fault if sufficient manufacturer’s data is available. Once the magnitude of the hazard has been recognized, appropriate safety practices such as correct body positioning can also be incorporated into safe work procedures. If the blast hazard is high, or if it is in a limited space, the blast can severely injure or kill a person. In that case, remote switching and remote racking equipment can be used instead of a technician. If the arc event does happen, the remote equipment is destroyed and the technician is not injured. If these conditions are present, serious consideration should be given to not allowing personnel in the area during specific switching and racking operations.

Selection of electrical protective equipment

Most employers, operators, and electricians are knowledgeable in the selection and inspection requirements for electrical PPE used for the prevention of electrical shock hazards, as well as head, eye, hand, and foot protective equipment (Figure 4). All of these requirements are readily found in OSHA 1910, Subpart I, Personal Protective Equipment. Unfortunately, some people have limited knowledge or experience of the electrical arc flash and blast hazards that may be associated with the maintenance and operation of energized electrical equipment and the necessary protective clothing and equipment required (Figure 5).

Figure 5. Some people have limited knowledge or experience of the electrical arc flash and blast hazards that may be associated with the maintenance and operation of energized electrical equipment and the necessary protective clothing and equipment required.

OSHA 1910.132(d) states, “The employer shall assess the workplace to determine if hazards are present, or are likely to be present, which necessitates the use of personal protective equipment (PPE). If such hazards are present, or likely to be present, the employer shall select, and have each employee use, the type of PPE that will protect the affected employee from the hazards identified in the hazard assessment.”

OSHA 1910.132 (f) — Training (1) states: “The employer shall provide training to each employee who is required by this section to use PPE.” According to the OSHA 1910 standard, each employee shall be trained to know at least:

- when PPE is necessary

- what PPE is necessary

- how to properly don, doff, adjust, and wear PPE

- the limitations of the PPE

- the proper care, maintenance, useful life, and disposal of PPE.

Included in this hazard assessment should be the three electrical hazards: shock, arc flash, and arc blast. OSHA 1910.137 identifies the selection, inspection, and use requirements for electrical PPE. OSHA doesn’t identify specific clothing and equipment that should be worn to protect the employee from the arc flash hazards, but OSHA does specify what type of clothing is prohibited. 1910.269(l)(6)(ii) requires that “the employer shall train each employee who is exposed to the hazards of flames or electric arcs in the hazards involved.”

Additionally, 1910.269(l)(6)(iii) states: “The employer shall ensure that each employee who is exposed to the hazards of flames or electric arcs does not wear clothing that, when exposed to flames or electric arcs, could increase the extent of injury that would be sustained by the employee.” This clothing includes meltable fibers such as acetate, nylon, polyester, polypropylene, and spandex, which “could increase the extent of injury,” as noted by OSHA. Natural fibers such as cotton, wool, and silk, can be worn as under-layers if the outer layers consist of arc-rated clothing that is rated for the available incident energy.

NFPA 70E 130.7(C)(9) states: “Clothing and equipment required for the degree of exposure shall be permitted to be worn alone or integrated with flammable, non-melting apparel. Garments that are not arc-rated shall not be permitted to be used to increase the arc rating of a garment or of a clothing system.”

OSHA requires protection from the hazards of electricity in 1910.335(a)(2)(ii) which states: “Protective shields, protective barriers, or insulating materials shall be used to protect each employee from shock, burns, or other electrically related injuries while that employee is working near exposed energized parts which might be accidentally contacted or where dangerous electric heating or arcing might occur.”

Summary

In resolving the issues in analyzing electrical hazards in an industry, we must follow a path that will lead to a comprehensive analysis of the problems that exist and provide appropriate PPE and clothing. An analysis of all three hazards — shock, arc flash, and arc blast — must be completed and steps taken to prevent injuries. The following are steps that should be taken to ensure adequacy of the electrical safe work practices program and training of qualified electrical personnel:

- conduct a comprehensive job task analysis

- complete a task hazard assessment including the shock, arc-flash, and arc-blast hazards

- assess other hazards, such as slip, fall, struck-by, or environmental

- analyze task for the PPE needed

- conduct training needs assessment for qualified and non-qualified electrical workers

- revise, update, or publish a complete “Electrical Safe Work Practices Program.”

Regulatory agencies and standards organizations have long recognized the need to analyze the hazards of electrical work and plan accordingly to mitigate the hazards. Unfortunately, many in the electrical industry have chosen to take their chances, largely because nothing bad has happened yet. As more information becomes available on the economic and human costs of electrical accidents, it’s hoped that more individuals in the industry will recognize the need for performing a hazard analysis and the need for having an electrical safe work program that emphasizes hazard identification and abatement.

To learn more about electrical safety at your plant, browse our list of training classes