Partial discharge 101: Secrets, tips, and tricks from an electrical professional

Most electrical professionals began our careers with fairly good knowledge about the practical aspects of our jobs. We understood voltage, current, power, and resistance. We mastered the more esoteric areas such as electrical fields and stress control, and only revisited these topics if our day-to-day job required it.

Partial discharge (PD) is one of those areas where we might have learned how to identify it or how to use a test set. However, most of our roles have not exposed us to the ins and outs of this topic. In this article, I share some unexpected things I have learned while working in the field on partial discharge issues. I hope this includes the secrets, tips, and tricks you always wanted to know about partial discharge but were afraid to ask.

Can cable termination mistakes cause PD?

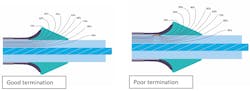

Cable termination procedures are precisely engineered, and any failure to follow them closely can lead to voids, field concentration, and partial discharge. An example of this can be seen in Figure 1, where an overly large gap that was not filled with mastic led to failure.

Furthermore, cable terminations are specifically engineered to ensure that voltage stresses do not exceed the insulation capability at any point. This is accomplished by ensuring that the voltage gradients across the insulation are even (see Figure 2).

When a termination containing multiple layers and different materials is exposed to an electric field, the voltage stresses are larger in the areas of lesser permittivity. Air has a permittivity about 2.3 times lower than insulation, so a void in the termination will have approximately 2.3-times higher field stresses. Combined with a 10-times lower dielectric strength, this leads to discharge across the void.

Voids can be caused by common mistakes in terminations, and Figure 1 also shows how electrical stress is greater in and around the void. Failure to completely fill gaps between the insulation and conductors with mastic is very common. Imprecise trimming of semiconductor layers can leave a void where the stress tube cannot fill the poorly trimmed section. Failing to fully clear the semiconductor layer off the insulation causes a concentration of stress and results in PD even if there is no void.

Can incorrect RFCT placement induce PD?

When performing an online partial discharge test on a cable, a radio frequency current transformer (RFCT) must be attached to the cable ground strap. In placing the RFCT, think 95% about safety and 5% about getting a good signal. Improper placement of an RFCT can affect both safety and signal. For safety reasons, ensure you have a solid ground capable of withstanding any phase-to-shield fault current.

Also ensure the RFCT is away from the termination and close to the ground bar so the RFCT is still safe if the ground does separate. Figure 3 shows an RFCT placed on an adequate ground close to the main ground bar and away from the termination.

Is that the only reason you should position the RFCT away from the termination? Remember that the termination is where the electric field goes from nice and contained inside the shield to free and unrestrained after the shield cut-back. The termination is designed to allow the field to spread out gradually so there is a lesser field but evenly distributed around the termination.

The closer you get to the termination, the stronger the field becomes. Allowing the RFCT inside that field can induce PD. It probably will not lead to failure unless it is very close, but it will make it impossible for that RFCT to discern any real PD.

What are contact discharge and floating metal discharge?

Contact discharge is caused by a poor high-voltage connection where sparks can jump across the gap at set times on the sine wave when the voltage level is high enough. These defects usually produce heat as well as ultrasonic sound that can be detected.

A related discharge – floating metal discharge – is an electrical discharge that takes place due to floating metal in the electric field. The floating metal typically acquires an electric charge from the field and then discharges to ground, the conductor, or via corona through the air. Common examples include tools or hardware left in a cabinet after work is performed.

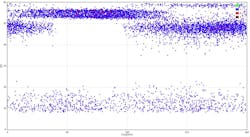

Contact discharge and floating metal discharge have characteristic phase resolved partial discharge (PRPD) plots where the level of discharge is consistent as the voltage increases (see Figure 4). These two types of discharge emit similar patterns, so it can be difficult to differentiate between the two.

The phase resolved pattern indicates that PD magnitude does not change despite the change in voltage. This is because the distance from the gap at the poor high-voltage connection or the floating metal to the live conductor is constant; therefore, the flashover voltage remains the same. The discharge phase angle actually moves with each succeeding discharge due to the physics of this type of discharge. The variance in phase and consistency in discharge amplitude produces these characteristic flat, broad lines in the PRPD. This characteristic can be used to identify this type of discharge and make it easier to find the offending component.

Contact discharge can cause failure due to the poor high voltage connection, whereas floating metal discharge tends not to lead to catastrophic failure. Both discharge types create a strong signal that often masks more damaging types of discharge. Ensure you eliminate both discharge types so you can see other discharge sources.

Is PD testing better if cabling is grounded at one end or both?

When you design a cable system, you have an option of grounding the shield at one end or both ends. If one end is ungrounded, a sheath voltage limiter (SVL) is typically placed on that end. The shield of a cable capacitively and inductively couples to the conductor, thereby acquiring potentially dangerous voltage. If both ends are grounded, the sheath voltage will be lower than if one end is an open circuit, especially during a fault. The downside of grounding both ends is that circulating currents can heat the cable and reduce its ampacity.

If a cable grounded at one end shows PD, the current has nowhere to go except the ground strap where the RFCT is located. This allows you to measure the total PD current. If the cable is grounded at both ends, the PD current will divide according to the ratio of impedances in either direction which gives a lower reading. However, there is a bright side: Testing both ends of the cable allows better sensitivity overall. A small discharge on one end might not be visible at the other end.

Is there a standard for acceptable PD levels in cables?

The world of electrical testing is largely predicated on the fact that we can assign a threshold. Above the threshold is considered bad, and below the threshold is considered good, or vice versa. As an example of the latter, in an insulation resistance test at 1 KV, above 100 Megaohms is generally considered good for many equipment types, while below 100 Megaohms is suspect or bad. These test methods and thresholds are codified in international, peer reviewed, and balloted standards to ensure they are accurate.

The world of partial discharge testing has very few approved standards, and most of them contain vague words like “should” and “may” instead of “shall” and “must.” Cable PD testing is especially void of standards that include hard and fast thresholds. ANSI/NETA MTS 2019 is the first United States standard to include online PD testing, but it doesn’t cover cables. IEEE 400.3 is specifically for field PD testing of cables, but it has no thresholds.

This lack of standardized acceptance levels can be traced back to the very nature of PD. It is an unfortunate fact that the absolute PD level is not directly relatable to the likelihood of failure or the time to failure. PD levels go up and down with a variety of influencing factors: Voltage, current, ambient temperature, relative humidity, time since inception, defect carbonization, and other factors. With all these variables unrelated to the test method, it is difficult to arrive at threshold levels. Trending over time or comparison to similar assets remains the best way to gauge the severity of PD. You may not be able to predict when something will fail, but you can identify bad actors for further study.

Which is better: online or offline PD testing?

This is a bit of a trick question. The tests are quite different, and they tell us different things. Both have their place in any maintenance and reliability program. It is important to understand their different strengths.

Online PD testing is usually the first step. You can test all your assets quickly and efficiently to see what is good and what needs further study. You are testing under real-world conditions of voltage, current, frequency, and load. If PD does not exist in the real-world conditions, there is no need to be too concerned. You can test all your assets without taking anything out of service or opening any panels to do the tests. Typically, a very small percentage of assets record any PD. The downside is that online PD testing will tell you less about PD than an offline test.

Offline PD testing is as close as you can get to factory testing in the field. You can vary voltage and see noise-free PD patterns. You can see exactly at what voltage PD begins and ceases. Unfortunately, it’s not all good news. You must take the equipment out of service and bring in large, heavy, expensive test equipment. You are also not working in a real-world condition, so results may not be fully representative of normal conditions. An offline test takes 10 to 20 times longer than an online test. The frequency is typically not power system frequency, and there is no load current, so the temperature profile is also different.

The global best practice is to do online testing or monitoring on all assets and do offline tests on the small population of assets that give indications of PD online.

Can you find PD inside switchgear by testing the cable?

Transient earth voltage (TEV) is a standard technique for finding partial discharge inside medium-voltage metal-clad switchgear. The TEV effect, discovered in the late 1970s by Dr. John Reeves, has become the basis for non-invasive testing for internal discharge. Voltage is induced on the outside surface of metal-clad gear as a result of discharge inside the gear. This voltage is a narrow pulse of a few microseconds and amplitude in millivolts. Measuring TEV can be very difficult because the signals of interest are hidden in noise.

One trick we have learned is that performing a TEV test on the outside of a cable exiting the cubicle is an excellent way to find PD inside the cubicle. A TEV probe on the outside of the sheath will couple to the shield and often provide a higher signal than the outside of the switchgear. The PD pulse in the switchgear will travel down the conductor and radiate to the shield. However, gaining access to the cables within a meter of the switchgear is not always possible. With IEC-type gear, the cables are exposed. In most cases with ANSI gear, you will need access below the cabinet. Many industrial substations are raised or have a basement that allows access. If at all possible, try it out.

How soon after energizing can you see PD?

Traditional knowledge held that partial discharge took years or decades to develop. The standard response was, “All my equipment is new! I don’t need to do PD testing.” In some instances, PD takes a long time to start. The thermal cycling that occurs throughout device operation can cause voids over time, and internal discharge can take decades to cause failure. However, as we have learned recently, early-life PD and failures are quite common. The oil sands region of Alberta, Canada, has seen explosive growth in the past 25 years, and the demand for jointers outstripped the qualified supply. Cable failures within the first 12 to 18 months were common. Data centers and windfarms have similarly driven cable installation rates to rise, and early failure rates in those applications are well above acceptable levels.

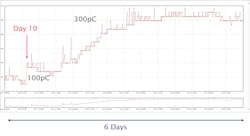

If the conditions are right for PD, there is no physical reason for it not to start immediately. It may be so low as to be undetectable at first, but it can be present. PD is more likely to be caused by workmanship than by aging, and bad workmanship can be there from day one.

For example, in Figure 5, a monitoring system was installed on a cable with new splices; PD was detectable by day 10. By day 14, it was 300 pC — not quite ready to fail, but clearly a rapid increase immediately after energizing. In another case, Figure 6 shows an extra high voltage termination that failed within days of energization. PD would have been detectable immediately.

Conclusion

I hope these few examples have been interesting and enlightening. While partial discharge is still a developing topic in our industry and we continue to find new things every day, the information we can learn about our assets is worth the learning curve.

About NETA

This article was provided by the InterNational Electrical Testing Association (NETA). NETA was formed in 1972 to establish uniform testing procedures for electrical equipment and systems. Today the association accredits electrical testing companies; certifies electrical testing technicians; publishes the ANSI/NETA Standards for Acceptance Testing, Maintenance Testing, Commissioning, and the Certification of Electrical Test Technicians; and provides training through its annual PowerTest Conference and library of educational resources.

About the Author

William G. Higinbotham

William G. Higinbotham is president of EA Technology LLC, where he is also responsible for sales, service, support, and training on partial discharge instruments and condition-based asset management. He is an IEEE Senior Member and is active in the IEEE Power Systems Relaying Committee, and has co-authored a number of IEEE standards in the field of power system protection and communications; he also holds one patent in this area.