Process layout

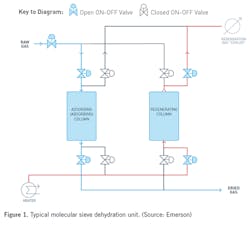

In a molecular sieve dehydration unit, the hydrocarbon fluid flows over the adsorption beds to remove moisture. As the beds reach saturation, switching valves reverse position, allowing hot regeneration gas to dry and regenerate the spent molecular sieve bed. A molecular sieve unit can contain two or more beds, with one bed being regenerated while the other(s) are drying gas (see Figure 1).

Switching valves are key to reliable performance

The performance of a molecular sieve unit is critically linked to the performance of the switching valves. The drying process itself requires tight sealing between the adsorption and regeneration streams to maintain efficiency. Mechanical reliability is also paramount since these units can run for years between turnarounds, while switching two to three times a day.

These service demands are difficult to meet, given the constant thermal cycling between ambient feed and 500+ degrees Fahrenheit regeneration gas, along with the presence of abrasive dust created by the constant expansion and contraction of the beds. Along with a high degree of mechanical reliability, the valves must continuously meet increasingly strict fugitive emission requirements, even as they are constantly operated.

Historically, the industry has used rising stem ball valves (RSBVs) that employ mechanical shutoff, instead of the process pressure-assisted sealing typically used in gate and ball valves. Mechanical sealing provides tight bidirectional shutoff, even with minimal pressure differentials and constant thermal cycling. In addition to tight shutoff, an RSBV offers eccentric motion, moving the ball away from the seat before turning to avoid excess wear from abrasive dust.

Understanding the advantages of double-acting actuators

Back to basics: Fluid sealing school

Over time, industry has seen two trends driving RSBVs toward obsolescence. First, the maximum fugitive emission rates have been reduced from 10,000 parts per million to as low as 100 parts per million, and these limits are being enforced much more aggressively. Increasingly, emissions are becoming the limiting factor in deciding how long units can stay online. Rising stem valves tend to have about 100 times the emissions of rotary valves, and the reciprocating nature of the stem makes it very difficult to keep an RSBV in compliance without constant maintenance.

A second trend is an increasing desire to extend turnarounds to five and even seven years. While RSBVs offer low friction on the sealing trim, the wear on the area of the stem mechanism that forces the ball away from the seat is extreme. Eventually the stem deforms, creating excessive seat leakage. Whether due to either stem fugitive leaks or internal seat leaks, the RSBV no longer meets industry requirements for mechanical reliability, ultra-low emissions, and long-lasting bidirectional shutoff between turnarounds.

A modern solution

With the deficiencies of the RSBV becoming more apparent, industry was forced to examine new options for switching valves. One design emerged as a significant improvement, the double eccentric C-ball valve (see Figure 2). This design offers the same mechanically assured shutoff as an RSBV, with zero leakage bidirectional shutoff and low-wear eccentric motion.

However, the valve has a much simpler and more rugged design than an RSBV. It also has no stem wear, and it utilizes true rotary motion to greatly minimize emissions. With the same face-to-face and flow coefficients as an RSBV, a double eccentric C-ball valve is a drop-in replacement.

Most important to molecular sieve operators, double eccentric C-ball valves can operate for eight years or more without maintenance. During that time, they will continue to meet fugitive emission requirements, with no required adjustments or maintenance in the stem area, while continuing to provide tight bidirectional shutoff.

Double eccentric c-ball design details

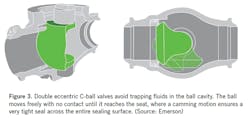

Double eccentric C-ball valves incorporate a state-of-the-art design to meet molecular sieve switching requirements. These valves employ a C-shaped ball, which moves along two axes to achieve tight closure (see Figure 3).

The C-ball utilizes double offset trunnions to create a camming motion. This allows the valve to seal independent of process pressure, with the sealing force coming from the torque applied to the stem as the C-ball cams into the seat. The camming effect also moves the C-ball away from the seat during the opening stroke to minimize wear when abrasives are present. The fixed seat does not require springs or dynamic seals, eliminating any possibility of contamination.

The combination of fixed metal seats, mechanical sealing independent of process pressure, low wear, a low emissions design, and consistency with process designs make the double eccentric C-ball valve the best option for molecular sieve switching service. The valve design is a proven technology with long service life and low cost of ownership (see Figure 4).

Double eccentric C-ball valves are available in sizes from ½ inch to 42 inches, and pressure classes up to 4,500 pounds. They are built to industry standards for ball valve isolation and meet the piping specifications required for on/off applications. Operators and end users are not only shifting toward this technology for molecular sieve switching applications, but also for a variety of other severe service applications that call for reliable shutoff and long life.

Severe service applications

When selecting valves for molecular sieve switching and other severe service applications, it is important to carefully evaluate the options and choose the valve that provides the best performance and lowest life cycle cost. Lower cost options may be available, but the added cost of constant valve repair and replacement, poor process efficiency, and increased fugitive emissions will far outweigh any initial savings in most applications. Consultation with experts can help quantify these costs and justify purchase of the valve designs providing the best long-term value.

This story originally appeared in the October 2021 issue of Plant Services. Subscribe to Plant Services here.

Bryan Hodges is the business development manager for AEV C-Ball Valves in the southern U.S. and Latin America at Emerson. Hodges has been in the valve and automation industry for over 12 years. He came to Emerson with the acquisition of AEV in 2018 as the North American sales manager, and has extensive knowledge of the cryogenic and severe service valve market.