Preventive maintenance checklist for centrifugal pumps

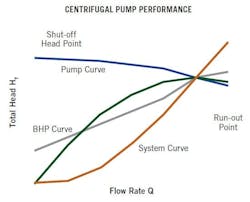

Whether operating under harsh or mild external conditions, environmental surroundings can put a great deal of stress on the pumping equipment that is required to run 365 days a year. To achieve optimum performance and reliability in a centrifugal pump, it must operate close to its best efficiency point, or BEP – the point at which the hydrodynamic unbalanced load of the centrifugal pump is at its minimum.

When a pump operates at a point some distance from the actual BEP, the result is an overall increase in hydrodynamic unbalanced load. This, in turn, affects the performance, reliability, and efficiency of the centrifugal pump. (Based on experience and experiments, the unbalanced load is at its peak at the shutoff point.)

In any operational atmosphere, a routine maintenance program will extend the life of a pump since well-maintained equipment lasts longer and requires fewer and less-expensive repairs. This article outlines a basic checklist for the preventive maintenance of centrifugal pumps.

Overview of pump efficiency

A machine’s efficiency indicates its ability to convert one form of energy to another. If one unit of energy is input to a machine and its output is one-half unit, the machine’s efficiency is 50%.

For a centrifugal pump, much of the work involves two very efficient machines: the pump itself and the AC induction motor that drives it. The centrifugal pump converts mechanical energy into hydraulic energy (flow, velocity, and pressure), and the AC motor converts electrical energy into mechanical energy.

Medium and large centrifugal pumps generally operate with efficiencies above 75%, and smaller ones usually fall into the 50% to 70% range. Large AC motors, on the other hand, approach an efficiency of 97%.

The overall efficiency of centrifugal pumps is the ratio of the water (output) power to the shaft (input) power, and it is described by the following equation:

Ef = PW / PS

Where:

Ef = efficiency

PW = the water power

PS = the shaft power provided to the pump shaft in brake horsepower (BHP)

And:

PW = (Q x H) / 3,960

Where:

Q = Flow (gallons per minute, gpm)

H = Head (feet)

3,960 = converts to BHP

For example, a pump that produces 100 gpm at 30 feet of head and requires 1 BHP will have an overall efficiency of 75.7% at that flow point.

The total efficiency of a centrifugal pump is the product of mechanical, volumetric, and hydraulic efficiencies. Mechanical efficiency accounts for losses in the bearing frame, stuffing box, and mechanical seals. Volumetric pump efficiency comprises losses due to wear ring leakage, balancing holes and vane clearances (in the case of semi-open impellers). Hydraulic efficiency includes liquid friction and other losses in the volute and impeller.

While mechanical and volumetric losses are important contributors to total efficiency, hydraulic efficiency is the largest factor. There are various conditions that decrease the efficiency of a centrifugal pump:

- Heat generated due to packing

- Rubbing between wear rings and maintaining impeller clearances

- Recirculation using a bypass line from the discharge of the pump to the suction

- Double volute design

- Throttled discharge valve

- Corroded internal pump passages that cause fluid turbulence

- Obstacles, hindrances, or any sort of restrictions inside the piping passages that might include foreign particles or dirt

- Overlubricated bearings

A detailed record of preventive maintenance performed and required repairs should be kept to aid in diagnosing problems and to eliminate or minimize any future equipment downtime. Operators who adhere to a preventive maintenance program will reap the benefits of a facility that functions without encountering breakdowns and out-of-service situations.

Pump manufacturers supply a manual with recommended maintenance procedures for their centrifugal pumps. However, routine preventive and protective maintenance practices should, at a minimum, include the monitoring of the following:

- Bearing and lubricant condition. Monitor bearing temperatures, lubricant level, and vibration. The lubricant should be clear with no signs of frothing. Excessive vibration and an increase in bearing temperature may indicate imminent failure.

- Shaft seal condition. The mechanical seals should show no signs of visible leakage. Some packing leaking is normal, but this should not exceed a rate of about 40 to 60 drops per minute.

- Overall pump vibration. Imminent bearing failure can be preceded by a change in bearing vibration. Excessive vibration can result from a change in pump alignment or cavitation resonances between the pump, its foundation, or the valves located in the suction and/or discharge lines.

- Pump discharge pressure. A gradual decrease in the developed head pressure of the pump may indicate that the impeller clearance has widened. An impeller clearance adjustment may be required to restore the pump to its intended design performance.

Annual maintenance

Once a year, the pump’s performance should be checked and recorded in detail. Performance benchmarks should be established for a new pump during the early stages of a pump’s operation, when the installation adjustments are correct. This benchmarking data should include:

- The head pressure developed, as measured by the suction and discharge gauges

- Centrifugal pump flow rate

- Motor amp draw

- Pump vibration signature

During the annual assessment of a pump’s performance, any changes in the benchmarks should be recorded and used in determining the level of maintenance that may be required to get the pump back to operating at its BEP.

Quarterly maintenance

The following maintenance tasks should be performed on a quarterly basis:

- Verify the integrity of the pump’s foundation and check the hold-down bolts for tightness.

- For oil-lubricated pumps, change the oil after the first 200 hours of operation for a new pump, and then after every three months or 2,000 operating hours, whichever comes first. For grease-lubricated pumps, bearings should be greased every three months or 2,000 operating hours, whichever comes first.

- Check the shaft alignment.

- Grease the motor bearings according to the manufacturer’s instructions.

Bearing lubrication tips

Any centrifugal pump operation and maintenance program must emphasize bearing lubrication. Realistically, all pump bearings will eventually fail. When two surfaces rub together, whether lubricated or not, friction will win in the end.

- For oil-lubricated bearings, use only non-foaming and non-detergent oils. Avoid over-lubrication which can be just as damaging as under-lubrication.

- Excess oil will cause a slightly higher horsepower draw and generate additional heat, which can cause frothing of the oil. If there is cloudiness when checking the condition of the lubricating oil, it may be an indication of excessive water content from condensation. If this is the case, the oil needs to be changed immediately.

- For pumps equipped with re-greaseable bearings, avoid mixing greases of differing consistencies or types. Also, note that the shields must be located toward the interior of the bearing frame. When re-greasing, confirm that the bearing fittings are absolutely clean to prevent contamination, which can decrease bearing life.

- Over-greasing must also be avoided, as this can cause localized high temperatures in the bearing races and create caked solids.

Additional parts examination

For cases where an operator needs to replace a part on a malfunctioning pump, take the opportunity to examine the pump’s other parts for signs of fatigue, excessive wear, and cracks. Any worn parts should be replaced if they do not meet the following part-specific tolerance standards:

- Bearing frame and foot. Inspect for cracks, roughness, rust, or scale. Machined surfaces should be free of pitting or erosion.

- Bearing frame. Inspect all tapped connections for dirt. Clean and chase threads as necessary. Remove all loose or foreign material. Inspect lubrication passages to be sure that they are not blocked.

- Shaft and sleeve. Inspect for grooves or pitting. Check bearing fits and shaft runout, and replace the shaft and sleeve if worn or if the shaft runout is greater than 0.002 inches.

- Casing. Inspect for signs of wear, corrosion, or pitting. If wear exceeds a depth of 1/8-inch, the casing should be replaced. Check gasket surfaces for signs of irregularities.

- Impeller. Inspect the impeller for wear, erosion, or corrosion damage. If the vanes are bent or show wear in excess of 1/8-inch deep, the impeller should be replaced.

- Frame adapter. Inspect for cracks, warpage, or corrosion damage and replace if any of these conditions is present.

- Bearing housing. Inspect for signs of wear, corrosion, cracks or pits. Replace housings if worn or out of tolerance.

- Seal chamber/stuffing box cover. Check for pitting, cracks, erosion or corrosion. Inspect for any wear, scoring or grooves that might be on the chamber face. Replace if worn more than 1/8-inch deep.

- Shaft. Check the shaft for any evidence of corrosion or wear and straightness, noting that the maximum total indicator reading (TIR) at the sleeve journal and coupling journal should not exceed 0.002 inches.

- Severe service conditions. If the pump is used in severe service conditions, such as in highly corrosive liquids, maintenance/monitoring intervals should be shortened.

Conclusion

Follow these recommendations to guarantee an efficiently performing centrifugal pump that meets design expectations and provides service for an extended period of time with minimal repairs and shutdowns. Consult the pump manufacturer’s manual for maintenance requirements that are specific to certain models and may not be listed here.

Implementing these maintenance recommendations may seem daunting, but it is only through a routine such as this that a fluid-handling operation can maximize the service life of the equipment while enhancing the safety of plant personnel and the environment.

About the Author

David Holland and Ronald Burg

Mahan's Thermal Products

David Holland is vice president at Mahan’s Thermal Products. He has a degree in mechanical engineering, which has helped him acquire an extensive background in general contracting and mechanical contracting. He also has extensive experience in the design and construction of mechanical systems and controls. Contact him at [email protected]

Ronald Burg writes extensively for the Mahan’s blog and has worked extensively in the heat exchanger industry. He was factory-trained at API BASCO in Buffalo, NY, and is factory-certified as an authorized service provider for Alfa Laval.