4 pump types for difficult fluids

In brief:

- There are four common types of reciprocating pumps - power pumps, power diaphragm pumps, air-operated pumps and air-operated piston pumps.

- Power pumps convert a rotary motion into reciprocating motion that can develop more than 40,000 psi discharge pressure or deliver more than 4,000 gpm.

- Diaphragm pumps have no rotating seals, are physically compact, require no electricity, cab self-prime, run dry and pass entrained solids, which makes them ideal for corrosive and abrasive fluids, hazardous environments, where space is limited, and portability is required.

This is the fourth in a series of five articles based on Hydraulic Institute’s comprehensive e-learning course, “Positive Displacement Pumps: Fundamentals, Design and Applications.”

Overview

Since the third century B.C., when Ctesibius built a basic hand-operated pump that could transfer water, reciprocating pumps have played a significant role in the development of civilization. Today, reciprocating pumps have developed into technically advanced machines capable of delivering more than 40,000 psi of discharge pressure.

Reciprocating pumps comprise a major segment of the positive displacement technology category. Reciprocating pump designs handle a full range of liquid characteristics, including low viscosity chemicals, high particle content slurries and high viscosity liquids. Given this operating range, they’re often the technology of choice for difficult applications.

The main difference between rotodynamic and reciprocating pumps is that for a given speed, a rotodynamic pump’s flow rate can be varied from zero to a maximum. Conversely, reciprocating pumps have nearly constant flow for a given speed, regardless of pressure. Reciprocating pumps have several common operating characteristics. This includes a constant fluid delivery (volume) per stroke and the mechanical trapping of the fluid by means of suction and discharge valves. The reciprocating motion typically produces pressure pulsations and additional devices to reduce pulsation, such as pulsation dampeners or attenuators. Additionally, as with many PD pump types, systems might require overpressure relief protection. Reciprocating pump efficiency varies widely across the category and is related to driver type and specific mechanical configuration.

Reciprocating pumps types

The four common types of reciprocating pumps reviewed here are:

- Power pumps: piston, plunger and direct acting (steam)

- Power diaphragm pumps, mechanically or hydraulically actuated

- Air-operated pumps: double diaphragm pumps

- Air-operated piston pumps

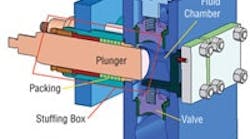

Power pumps are reciprocating machines in which a power end drives plungers or pistons within a valved cylinder. The power end (Figure 1) converts a motor’s rotary motion into reciprocating motion by means of a crankshaft, connecting rods and crossheads. The liquid end (Figure 2) connects to the power end and contains the plungers, packing, fluid chambers and valves. The plunger’s reciprocating motion in concert with other liquid-end components can develop more than 40,000 psi discharge pressure or deliver more than 4,000 gpm.

Figure 1. The power end converts a motor’s rotary motion into reciprocating motion by means of a crankshaft.

These pumps typically have 1, 2, 3, 5, 7 or 9 connecting rods and crossheads that drive an equal number of fluid plungers. An odd number of cylinders is preferred to reduce pressure pulsations. The oscillating pressure in each fluid chamber generates pulsations that range from suction pressure to discharge pressure. This pressure oscillation, cycling at 50 CPM to 500 CPM, is a leading contributor to pump failures; however, these pumps are constructed robustly to resist fatigue.

Figure 2. The liquid end connects to the power end and contains the plungers, packing, fluid chambers and valve.

It’s important to control the pressure in power pump systems. As the pump injects the displaced liquid into the discharge system, the pressure increases. The pressure continues to increase until it matches the system requirements. If the system pressure isn’t controlled, the pressure continues to increase until something in the system ruptures, either in the pump or the driver stalls out. Equip power pumps with a pressure relief device to prevent the overpressurization beyond recommended limits.

Power pumps typically are used for low-viscosity chemicals, oils, high-pressure cleaning, ore slurries, drilling mud, reverse osmosis, saltwater injection, hot oil applications, blow out preventers and subsea applications.

Air-operated diaphragm pumps combine the reciprocating motion of a flexible membrane, called a diaphragm, with check valves to transfer fluid. Typically, these pumps have two diaphragms connected to a reciprocating shaft or connecting rod in which one side of each diaphragm is in contact with the liquid being pumped and the other side is in contact with the compressed supply of air or gas. An air motor pressurizes the two diaphragms alternately to produce the reciprocating motion. The process fluid pressure typically is equivalent to the supply air pressure; however, amplification devices allow specialized pumps to operate at pressures as much as three times the air supply pressure.

Figure 3. Diaphragm pumps are available in many materials of construction, have no rotating seals, are physically compact and require no electricity.

Diaphragm pumps are available in many materials of construction, have no rotating seals, are physically compact and require no electricity (Figure 3). These characteristics make air-operated diaphragm pumps ideal for transferring corrosive and abrasive fluids, operating in volatile environments, for installations where space is limited and portability is required. Other benefits are the ability to self-prime, run dry and pass entrained solids.

Air-operated piston pumps use a reciprocating piston and check mechanism to produce fluid flow and pressure. They can produce fluid pressures in excess of 6,500 psi, so they’re popular for pumping viscous fluids such as sealants, adhesives, inks and lubricants. Piston pumps can meet the needs of applications involving dispensing, metering or transferring fluid. As a result, piston pumps are built in many styles and configurations.

Figure 4. The air motor drives the lower end and the reciprocating motion of a smaller piston produces fluid pressure and flow.

The air motor and lower end (Figure 4) are the two major components that control flow rate and pressure. The air motor converts compressed air into reciprocating motion and is available in several sizes that are defined by the diameter of the air piston. The air motor has a major piston connected to the lower end. The air motor drives the lower end and the reciprocating motion of a smaller piston produces fluid pressure and flow.

The ratio of the area of the larger air motor piston to the smaller piston allows for the amplification of the fluid pressure over that of the supply air pressure. For example, if the pump is being operated by 100-psi air and the air motor piston is 4 times the area of the lower end, the fluid discharge pressure is 400 psi.

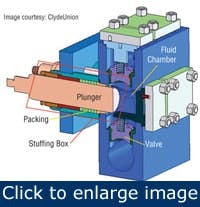

Power diaphragm pumps combine the advantages of reciprocating plunger and diaphragm pumps. This is done by means of separate liquid paths, one for the fluid being pumped and one for hydraulic fluid that pressurizes the fluid (Figure 5). This eliminates the dynamic seal in the pumped fluid loop that reciprocating plunger pumps require and enables leak-free operation.

Figure 5. The hydraulic power circuit is on the right (blue), and the pumped fluid circuit is on the left (yellow).

A diaphragm separates the two fluid circuits; suction and discharge valves pump fluid circuit control the flow. The diaphragm is the pumping element, and the plunger displacing hydraulic fluid induces its reciprocating motion. Multilayered diaphragms with integral alarm functions prevent pumped liquid leakage if a diaphragm ruptures. These features allow the fluid to be contained in the pump even when one diaphragm is damaged.

Power diaphragm pump designs are modular, allowing for electric motor-driven power frames with multiple pumping heads. Configurations can be simplex, duplex, triplex (Figure 6), quadruplex or septuplex.

Figure 6. Power diaphragm pump designs are modular, allowing for various configurations, such as this triplex.

In multihead configurations, common suction and discharge manifolds reduce pulsation caused by partially overlapping flows. Standard pump configurations are available; however, highly customized units with special valves, heating/cooling jackets and wetted parts materials such as titanium, duplex steel or Hastelloy are common. Power diaphragm pumps provide efficient leak-free pumping to 1,200 bar (18,000 psi) on a broad range of fluids, including those that are environmentally damaging, valuable, abrasive or viscous (to 250 kcSt). These pumps have proven their safety and reliability in numerous applications including chemical process, nuclear, pharmaceutical, cosmetics, biological processes, foodstuffs and onshore and offshore petrochemical installations.

Selection and application analysis

Pump selection is a complex and highly technical process that should be completed by a trained professional. The pumped fluid’s viscosity, specific gravity, temperature, solids content and its compatibility with the pump’s materials of construction should be evaluated. Components that come in contact with the fluid, including pump casings, seals, packing, diaphragms, plungers and valves must resist corrosion. The materials of construction specified for the pump often are the main cost drivers. Highly corrosive fluids might require more expensive materials such as duplex stainless steel, Alloy C, PVDF, PTFE and Viton, whereas inert fluids can be compatible with less expensive materials such as aluminum, steel, synthetic rubber and thermoplastics. Similar to fluid properties, environmental conditions also can affect pump construction. Atmospheric conditions might require special pump materials to resist corrosion or ensure groundability in volatile environments.

System variables such as piping configuration, inlet elevation, outlet elevation, power availability, operating pressure and flow rate determine the best reciprocating pump type and size. These system characteristics in combination with the fluid properties allow for validation that the reciprocating pump will self-prime and deliver the specified flow and pressure.

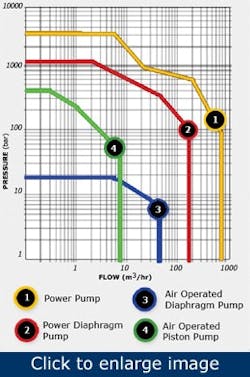

When the system demands are calculated and understood, the pump types that best fit the application can be selected using a range chart (Figure 7). More than one reciprocating pump type often is suitable for an application. It’s then up to the user to assess the unique features and benefits that each technology has to determine what’s appropriate for the application.

Figure 7. When the system demands are calculated and understood, the pump types that best fit the application can be selected using a range chart.

The Hydraulic Institute (HI) is the largest association of pump producers and suppliers in North America and is a global authority on pumps and pumping systems. Its mission is to serve as a forum for the exchange of industry information, while providing value-added services to member companies and pump users worldwide. Nearly 100 companies belong to HI, and engineering consulting firms affiliate as “Standards Partners.” For more information about the Hydraulic Institute, its member companies and Standards Partners visit www.pumps.org.

HI and Pump Systems Matter (PSM) encourages organizations to host the “Pump Systems Optimization: Energy Efficiency and Bottom-Line Savings” one-day course for their staff, customers, clients and others. The course offers attendees turn-key solutions and offers skills to identify significant energy savings opportunities, improve pump systems efficiency and reduce energy and operating costs, and create an action plan to execute energy conservation initiatives.

PSM provides product-neutral training on pump systems, where qualified instructors share their many years of experience. The course is already tested, proven and ready for delivery on your chosen schedule. In addition, course materials are professionally produced and ready for delivery.

Utilities, pump users, engineering consulting firms, energy service companies, pump or supplier OEMs, associations, federal, state, local or regional energy efficiency organizations will certainly benefit from hosting this course.

For more information about hosting a course, please visit www.pumpsystemsmatter.org or contact Kathy Doran at (973) 267-9700, ext. 216 or [email protected].