How to select the right positive displacement pump

In brief:

- Positive displacement pumps require a particular minimum absolute pressure at the input port.

- PD pump throughput is a function of viscosity, differential pressure and speed.

- PD pumps aren’t self-priming.

HI is the largest association of pump producers and suppliers in North America and is a global authority on pumps and pumping systems. Its mission is to serve as a forum for the exchange of industry information, while providing value-added services to member companies and pump users worldwide.

Along with e-Learning courses, HI also offers ANSI/HI Web-based Standards subscription packages. Web-based subscriptions provide company-wide access to the ANSI/HI Pump Standards for one or more simultaneous users, 24 hours a day, 7 days a week, from anywhere in the world. You might access your ideal subscription from the Web or download to view locally. Visit www.estore.pumps.org/subscriptions to learn more.

Attend any “Pumping System Optimization” course and receive seven PDH credit directly from HI. Those interested in hosting the course might do so at their own facility. For more information about attending or hosting a course in 2011, visit www.pumpsystemsmatter.org or call Kathy Doran at (973) 267-9700 X216.

This is the second article based on Hydraulic Institute’s new “Positive Displacement (PD) Pumps: Fundamentals, Design and Applications” e-learning course. The Hydraulic Institute (HI) is continuing its mission to drive industry innovation by delivering to pump professionals an indispensable resource that supports their continuing education needs.

Because fluid properties affect positive displacement pumps differently than centrifugal pumps, it’s critical to understand the interaction between the pump and the fluid and how the operation of positive displacement pumps differs from centrifugal pumps. Without this foundation of fundamental principles, effective understanding of the myriad positive displacement pumps is unnecessarily difficult.

On the most basic level, pumps provide pressure and flow that accomplish a specified task. This basic premise helps explain that positive displacement pumps produce flow, not pressure. The pressure the pump needs to produce is a function of the system’s frictional losses, restrictions and elevation changes.

Another basic concept is the difference between gauge pressure and absolute pressure (Figure 1), as these two reference points have caused more than their fair share of confusion over the years.

Figure 1. Use these conversion factors to move between gauge pressure and absolute pressure.

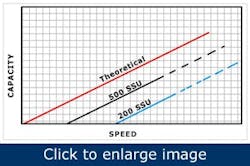

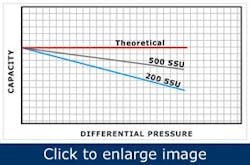

Positive displacement pumps theoretically produce flow that’s independent of discharge pressure, and the pump’s flow characteristics affect the system design and pressure. Figure 2 and Figure 3 show how differential pressure and speed affect the pump’s flow rate. The mechanism is a fundamental difference between positive displacement pumps and centrifugal pumps.

Figure 2. This chart depicts pump throughput as a function of speed with viscosity as a parameter.

Figure 3. This chart depicts pump throughput as a function of differential pressure with viscosity as a parameter.

Of course, nothing comes for free, so pumps require a certain input power to perform work.

The fluid counts

Fluid characteristics play a major role with positive displacement pumps because most handle fluids other than water. The most important property is viscosity, the fluid’s resistance to a shearing force, which quantifies how easily the fluid will flow.

Along with viscosity, it’s essential to understand how a fluid reacts to being pumped. A fluid can have a constant viscosity, at a particular temperature and pressure, regardless of the rate of shear. This is called a Newtonian fluid. If the viscosity varies with shear rate, the fluid is non-Newtonian.

Beyond viscosity, other fluid characteristics relate to positive displacement pump selection and operation. One such property is vapor pressure, the absolute pressure at which a liquid changes to a gas (Figure 4.) The primary influence of vapor pressure is on the net positive inlet pressure (NPIP) the pump requires. The NPIP is the absolute pressure above the vapor pressure that’s required to get the fluid into the pumping elements. At a fixed inlet pressure, the greater the vapor pressure, the lower the pressure available to get the fluid into the pump.

Figure 4. The fluid’s vapor pressure and the system pressure interact to produce the net positive inlet pressure the positive displacement pump requires.

The required inlet pressure is a pump characteristic determined by atmospheric pressure, fluid elevation level above or below the pump inlet, inlet line friction losses, vapor pressure and, in the case of reciprocating pumps, acceleration head. Other characteristics, such as temperature, solids content, fluid corrosivity and the inlet system also affect selection of the best pump technology with the best operating characteristics.

The selection

Once you understand the factors that affect pump selection, you can evaluate such factors as environmental considerations, power consumption and system requirements. These affect pumping system lifecycle cost, which nearly always exceeds the initial cost of the machine. Lifecycle costs are more fully explored in the Hydraulic Institute publication, “Pump Life Cycle Costs: A Guide to LCC Analysis for Pumping Systems.”