The vast majority of pumping systems run far from their best efficiency point (BEP). For reasons ranging from shortsighted or overly conservative design, specification and procurement to decades of incremental changes in operating conditions, most pumps, pipes and control valves are too large or too small. Pumping systems fail to convert the electric power they consume into fluid motion with anywhere near the economy, reliability and control inherently available in the finely engineered individual components.

Far too many pumps run 24/7 generating excess pressure, velocity, noise, vibration and heat that waste energy, tear up mountings, loosen and crack piping, and erode control valves. Others fail to produce the desired flows with the precision needed to maintain uniform, high product quality and process efficiency.

If you wonder how this has come to pass, you need look no further than the back offices.

The cautious and the careless

“Engineers tend to be careful and conservative,” says Greg Romanyshyn, technical director, Hydraulic Institute (www.pumps.org). “Their designs cover all contingencies, including upsets, to be sure the pump will not be the fault in the system -- the pump will deliver. But margins accumulate through the design, so in operation the pump is oversized and does not operate at BEP.”

The engineers’ caution is more than matched by contractors’ indifference to long-term operating costs. “People will design a piping system and analyze the structural aspects to death due to ASME codes, but they ignore fluid dynamics, which is the purpose of the system,” says Trey Walters, P.E., president and chief technology officer, Applied Flow Technology (www.aft.com). “Why is this so? Because it’s not being demanded by the facility owners, who have lost the expertise. The design firms are close on margins and not willing to pay for something the owner doesn’t demand. So there is a lack of demand for efficiency. As long as it works pretty well, no one pays any attention.”

Why care about over and undersized fluid handling systems if the plant seems to run OK? “The difference between running OK and running efficiently varies from pump to pump, process to process and plant to plant,” says Martin Bima, P.Eng., industrial systems engineer, Business Engineering Services, Manitoba Hydro, Winnipeg, Manitoba. “Unfortunately, after the typical pumping system is installed, it is considered commissioned as soon as it is making ‘enough’ flow and head, regardless of efficiency, operating point or power consumption. It is rarely reviewed until production is negatively affected or a catastrophic failure occurs.”

If the plant's goal is to make as much product as possible, the typical pump installation would be adequate, Bima says. “But if the goal is to lower the energy and maintenance costs per unit of product -- the MBA people's ears should be burning about now -- efficient pumping is one of the most important factors to review. Over and undersized pumping systems waste energy, reduce reliability and contribute to runaway maintenance budgets.”

Sending out an SOS

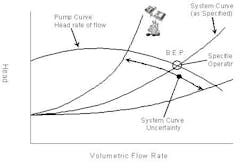

Generally speaking, in pump systems that contain restrictive or no control devices, an undersized pump operates on the right side of its curve and an oversized pump operates on the left side (Figure 1). “In each case, it’s far from its best efficiency point,” Bima says. “One way of thinking about it is for every kilowatt of power input to the pump, less is being transferred to the fluid. Where does the rest of the energy go? It has to be converted and dissipated somewhere, and it goes to noise, heat and vibration. Noise can be tolerated but the other two will reduce the expected life of the pump, increase maintenance cost, and may cause an unexpected failure.

“When a pump is running over or undersized, you are paying more for energy input, accelerating the wear on the pump, and reducing the life of its components.”

Operating a pump at part-flow is a primary cause of pump problems, second only to poor lubrication, asserts Heinz Bloch, P.E., principal of Process Machinery Consulting (www.machineryreliability.com). “Operating at flows lower than the BEP is inefficient,” Bloch says. “Moreover, this can cause pumps to experience excessive internal recirculation. Internal recirculation is not unlike cavitation. It can be of little consequence and can also be life-shortening. In high-energy pumps, internal recirculation can cause extreme damage in just a few weeks of operation.”

In the most common scenario, an oversized pump is paired with an oversized control valve. “The system uses, say, 80 gpm, but the pump wants to deliver 120 gpm,” says Romanyshyn. “The head is raised to a pressure that’s not needed, and excess head times flow is the energy wasted. The control valve consumes the wasted power with excess pressure drop, which shortens valve life.”

In a recent survey by Emerson Process Management of more than 200 sites all over the world, some 500 individuals involved in research, process engineering, procurement, operations and maintenance overwhelmingly reported that the number-one control valve problem is, “Our valves are oversized.”

During continuous process operations, control loops run in a very narrow throttling range - essentially steady-state at or near maximum continuous rating (MCR). The control valve dithers as small input signal changes result in small movements of the stem or shaft. “Today's higher-performing digital valve controllers can compensate for valve sizing errors,” says Michael McCarty, engineering manager, Fisher new product development at Emerson. “Their ability to precisely respond to the control system’s smallest requests can give the appearance of acceptable process loop performance.”

But improperly sized valves can lead to problems even when the plant appears to be running well. At full operating conditions, oversized valves are forced to throttle more close to the seat than designers intended. High velocity across the narrow opening causes wear and erosion. Impingement of these jets causes cut lines in the sealing surfaces, which reduces the element’s ability to control leakage when the valve closes, and erosion to the flow contour element, which alters the flow characteristic and throttling control. More severe cases can lead to vibration that causes additional wear damage and, ultimately, equipment failure.

Improperly sized control valves also can cause problems during process transients due to compromised rangeability. “A typical control valve with equal-percent flow characteristic has about a 30:1 turndown ratio,” says McCarty. “If it is oversized and throttling at the low end, the turndown ratio drops to approximately 3:1 or even less. As a result, startup conditions or turndown conditions to 25% MCR fall outside of the element’s ability to control, requiring extremely small valve movement and throttling essentially right at the seat or seal. Inherent clearance flow characteristics of some valves make control in this range impossible. In addition, the gain characteristics can cause instability, causing the valve to cycle.”

Though less common, undersized valves can cause larger problems during turn-up conditions or process spikes. “The inability of the valve to accommodate higher flow demands will alter the desired process conditions,” McCarty says. “This can change the process parameters leading to incorrect final product specifications and even lead to increased process pressures in ranges that lift safety relief valves.”

Undersized piping leads to similar problems. “If a pipe is undersized, it restricts the flow, and the pressure losses are large, so the pump has to be big. It wastes energy,” says Lev Nelik, P.E. president, Pumping Machinery Co., Atlanta. “At 100 hp and up, it begins to matter. For a 1,000 or 2,000 hp pump, savings can be significant, like $20,000 per year.”

On the rocks

Plant maintenance professionals looking for distressed pumping systems can start by using their ears. “The most obvious symptom is noise,” Bima says. “Cavitation due to undersizing and recirculation due to oversizing may each sound like someone has dumped a load of gravel into the casing of the pump. The intensity can range from one or two pops per second, to a deafening roar.”

When a pump is oversized, fluid remains in the pump and is mixed by the impeller rather than flung into the discharge piping. If a partially closed valve is opened and the flow rate through the pump increased, the sound may be reduced or disappear entirely.

In an undersized pump, “The motor overamps, hydraulics go unstable and the pump vibrates,” says Bill Livoti, industry engineer, fluid handling and petrochemical, Rockwell (www.rockwellautomation.com). Cavitation can cause damage and noise. Partially closing the discharge valve reduces or eliminates the sound.

Poorly sized control valves often can be identified by their normal operating positions. “During normal operations, valves throttling less than 10% or greater than 90% of valve travel are inappropriately sized,” says McCarty.

Control engineers can see poorly sized valves and rank them for process impact using loop performance diagnostic software. “If the performance supervision system determines process models for each control loop, then you can get a report showing the process models for all control loops that have valves,” says George Buckbee, vice president, product development at ExperTune (www.expertune.com). “Sort the list by the process gain, and you will have a very good idea which valves to pursue.”

When the process gain is large -- greater than 3% process variable (PV) per percent controller output (%OP, equivalent to the desired valve position), says Buckbee -- the control valve is oversized. A small movement of the valve results in a large movement of the PV. This makes the system difficult to control, and could lead to instability. Mechanical problems, such as stiction or hysteresis, are amplified with a large valve, causing process upsets.

Using the same report, undersized valves can be spotted by looking for process gain smaller than 0.3% PV per %OP. “Another way to spot undersized valves is to look for valves that are operating at limit,” Buckbee says. “If a valve is operating full-open for much of the time, there is a good chance that it is undersized. We should also point out that a valve that is fully open is not doing much to control the process.”

Other condition-monitoring methods may pick up deterioration that’s due at least in part from sizing issues. “Stress wave analysis can be used to measure friction and detect mechanical damage in equipment by ‘hearing’ impact events,” says Tim Shaw, chief technology officer, Swantech (www.swantech.com). It can detect problems at low levels where ultrasonic and vibration methods may not be effective. “It’s very sensitive,” says Shaw. It can detect skidding bearing elements, lube problems or subsurface cracks, even in new machines, to give “an extreme early warning,” he says, “We hear the chips.”

On feedwater and recirculating pumps that may be 20 feet underground, a stress wave system can be mounted at the top and listen to the pump via the shaft. A pump running outside its rated capacity “is probably screaming,” Shaw says. “It may not be wearing out, but it’s being operated in a way that will shorten its life.”

Re-rigging

Of course, the best way to deal with poorly performing pumping systems is to specify them right in the first place or redesign them using fluid modeling software. The Department of Energy and the Hydraulic Institute are making the job more straightforward by offering free Pumping System Assessment Tool (PSAT) and Pump System Improvement Modeling (PSIM) packages by download (see sidebar).

“Before any fix is attempted, it is extremely important to know what the system requirements are with respect to flow, pressure and variability,” Bima says. The best system design is one that meets the real-time requirements of the process while using the least amount of energy and operating at the best efficiency point. This will reduce energy costs, increase the life of the components and reduce the maintenance budget.

Most cures for existing systems require modifying or changing the pump, pump driver, control valve, piping or system demand. “There is a range of cheap and extensive fixes to over and undersized pumping systems, and these corrective measures would take us back to the first question,” says Bima. “Do you want to run efficiently or just OK?”

Undersized piping is a serious problem and one that’s becoming more common as owners outsource responsibility for plant design to contractors. Big pipes have a higher initial costs than big pumps, so the low-bidding contractor may skimp on pipe size and use larger pumps at higher heads to make it work.

The result is an inefficient system that’s expensive to correct. “On an existing unit, if you have a 4-in. pipe, how can you get a 6-in. pipe in there?” asks Nelik. “You can run a second pipe, but you have to sneak it in there, and things are in the way.”

For oversized pumps, where flow is reduced below the design point and the pressure is typically much higher than necessary, there are several ways of fixing the problem.

- Re-size the impeller: Pump capacity often can be adjusted by changing the impeller. “If the size of the impeller is such that you can trim it, that’s generally the least costly,” says Romanyshyn. “If the impeller is already at the minimum, you may have to change the pump.”

- Divert flow from the inlet to the suction side: “Bypass may solve some problems but it’s pretty much all wasted energy,” says Romanyshyn. It also can lead to poor control. “A stock blending system on a paper machine uses bypass lines to control flow,” says Mike Pemberton, manager, performance services, ITT (www.gouldspumps.com). “When you move a bypass valve, pressures change all through the line. You need consistent pressure for quality paper.”

- Change the pump to more closely match the requirements.

- Install speed control or a variable-frequency drive (VFD): But check that you have an inverter-duty motor that can be operated at the target speed without overheating. “On vertical pumps, check for harmonics with the impeller,” says Romanyshyn. “On multistage rotary turbine pumps with long rotors, a VSD can reduce the operating speed towards the first critical speed. If so, the rotor becomes unstable.” Clearances might close up and the rotor might contact the stator. Before installing a VFD, it’s wise to consult the pump manufacturer.

On undersized pumps, flow is greater than design and pressure is sometimes lower than required. “With an undersized system, the key question is, can I meet the operating goals?” says Ed Hardin, consultant, Hardin Consultants, Charlotte, N.C. First, look for something wrong such as a blocked pipe, a partially closed valve, a control valve that’s not operating properly, or a worn pump impeller.

“Has someone tried to ‘improve’ the system by putting in mismatched pumps?” Hardin asks. “Is the piping big enough, everywhere, for what you’re trying to put through? Did someone change out a valve and create an orifice?”

If low pump output is truly the problem, potential fixes include:

- Reduce the demand: Check the distribution system for uncontrolled flow, Bima says, “For example, someone washing their car with firewater.”

- Re-size the impeller.

- Change the pump.

- Install speed control: “In some cases, you can even run a pump above its nominal speed, but check with the manufacturer,” says Bima.

Each of the fixes should be assessed both technically and by using a life-cycle cost analysis. When capital cost, energy use and maintenance requirements are weighed against the energy savings and increase in reliability, the best solution will be obvious.

Several experts warned of problems with operating pumps in parallel. “If pumps in parallel have mismatched curves, they can end up fighting each other,” says Hardin. If one pump in a matched set must be replaced, “It’s often hard to find an identical pump for a replacement,” he says. You may have to undertake the difficult task of explaining to management why you need two pumps.

“Operating two seemingly identical pumps often causes one of the two to be driven off its curve into the low-flow region,” says Bloch. “Why not buy a wider impeller for one of the two pumps and allow it to operate by itself at higher flows than before?” He says it may require a different driver, but at today's energy costs, that may be the right solution.

Valves: When bigger isn’t better

When trying to correct poorly sized control valves, it’s good to understand the causes of valve sizing errors. “Our research confirms that there are four major contributors to valve sizing errors: safety factors, equal-percent flow characteristic, selecting line-sized valves and inaccurate process data due to changes in process conditions or conditions that are different from design,” says McCarty.

To correct systems with improperly sized equipment, it is vital to obtain accurate process data at all expected normal operating conditions. Then size the valve to perform optimally at these conditions. “The prevailing rules-of-thumb sizing and selection techniques are antiquated considering today’s available technology and the performance improvements they enable, such as the improved response accuracy of our FieldVue DVC6000 digital valve controller,” McCarty says. After the initial product selection, go back and verify that off conditions are compatible with the product for short durations.

Many products can be retrofitted in the field to correct for mis-sizing. Globe-style control valves, for example, have a number of available port sizes for a given body size. Changing the trim size will alter the throttling position of the flow element into a more optimal range. “Other products do not offer such flexibility and need to be changed out for a smaller or larger product,” says McCarty.

When a process is designed, people want to plan for the future. But when you design for a huge flowrate and only use a fraction of it, you run into problems. “You can use reduced-port trims for today’s flowrates, then, when expanding, change the trim,” says Todd Loudin, president, Larox (www.larox.fi).

Some designers don’t pay enough attention to Cv: the higher the Cv, the higher the flowrate. “People think, ‘I have a 6-in. line, I want a 6-in. valve,’” Loudin says. “In almost all cases, you’ll want a control valve one size smaller, especially if the valve has a high Cv like a Larox pinch valve.”

As a rule of thumb, a typical ball, butterfly or globe valve should be sized to be 60% to 80% open under normal conditions. “If it’s only 30% open, you have a problem and reduced trim may improve control,” Loudin adds. For pinch valves, the ideal is 10% to 50% open due to the geometry of the opening.

Paradise pays

Identifying, reengineering and correcting poorly sized systems is not high on every plant’s priority list, but can offer significant short-term payback when it increases reliability and control, and longer-term savings from reduced energy consumption. Start with the biggest pumps and pumping systems that are causing the most problems, and work down from there.

“I always tell plants to look first at the main water pumps,” says ITT’s Pemberton. Main water pumps are sized for maximum plant output. Parts of the plant are not operating at any given time, but the pumps run at full speed, all the time. “They run too low on the curve, so they cavitate and do not make output,” he says. “People think they don’t have enough capacity but the problem is the opposite.”

Tuning up the pumps will improve pressure control, which can have benefits throughout the plant, Pemberton adds. “Use variable speed or shut pumps off when they’re not needed with controls like PumpSmart.”

Pemberton has extensive experience evaluating and engineering pump systems for multiple manufacturers, and spoke to us while boarding a plane for yet another paper mill troubleshooting adventure. “Pay attention to seal water systems,” he says. “You need reliable seal water to avoid failures.

“You say you have spare pumps? Well, I was in a bleach plant with three 250-hp mill water pumps and a fourth installed as a backup and spare. The seal water pumps drew from the mill water. Over time, the plant had tapped other lines into the mill water and the pressure was swinging from 25 psi to 45 psi. They were trying to maintain 60 psi with a valve, but it wasn’t working. When the pressure dropped, seal water pump output went low and seals would crack. The plant was averaging 1-1/2 hours of downtime per month to fix seals, which backed up production and cost them $700,000 to $800,000 per year.”

Pemberton visited a paper mill that was considering his company’s condition-monitoring system to improve reliability of a problem pump. “When I came in, I saw they had a 300-hp unit pumping hot filtrate liquor into a 14-in. discharge pipe with a 10-in. valve that was only 40% open,” he says. “Along with wasted energy, this created a huge water jet inside the pipe. The pipe was bouncing all over the place, and they had constant pipe cracks, gasket damage and environmental leaks. They thought the high temperature of the fluid was cracking the pipe due to thermal shock.”

The mill added a variable-speed drive and reduced the motor from 300 to 200 hp. “The horsepower drop let them go from medium to low voltage, which cut the cost of the drive to a half or a third,” Pemberton says. “They got an 18-month payback on energy alone, which justified the entire project, but they also calculated savings close to $1 million the first year on maintenance and downtime. The system went from one of their major problems to out-of-sight, out-of-mind.”

Variable-speed drives can be used on many existing motors. “They’re now much less expensive than they used to be – cheaper than changing the piping – and more reliable than ever,” says Livoti. Power plant boiler feed pumps are a great opportunity for savings, according to Livoti. “You can size the pump to run at BEP at full-depth fire, but you must have adjustable-speed drive because you won’t typically use it there,” he says. “So many people fail to do this. Hundreds of plants are wasting the nation’s energy sources. It’s a crime and the whole country’s paying for it.”

These days, energy savings alone can justify a project. “On a low-static-head system, opening a valve 10% can cut energy consumption by 40%,” says Pemberton. “Compared to reliability and quality savings, saving energy is just icing on the cake, but you can use it to justify the project because it’s easy to calculate. You can calculate the reliability and quality savings after the project is done, when you can measure the improvements.

"A lot of this is invisible – if it ain’t broke, don’t fix it. We go in and identify opportunities, and they get totem-poled with all the other capital projects, but we’re trying.”

The best plants are starting to realize that pump optimization is not a project, it’s a process like continuous improvement. “I’ve seen data where a plant started putting variable-speed drives on pumps 10 years ago. They looked back and saw that availability had improved from 81% to 93%. Their pump and motor failures had dropped by a factor of four,” Pemberton concludes. “Do five a year and in five years you’ll have 25 pumps improved and be saving millions of dollars a year.”

Pump systems matter

Pump system energy efficiency improvement opportunities fall into two distinct categories: existing and new systems. The number of retrofit opportunities far exceeds the number of new systems each year, so the bulk of potential savings lies within these existing systems.

The average energy savings potential through economically viable pump system optimization projects is approximately 20%, although certain installations might realize significantly greater savings, ranging from 25% to 50%. If every facility in the U.S. implemented such measures, the savings would equal over 28,000 GWh/year, based on a midrange estimate (DOE 1998). This energy savings potential represents significant savings potential for industrial facilities and their owner/operators. Significantly, energy efficiency improvements to industrial systems usually provide improved reliability, productivity and reduced environmental costs.

The Hydraulic Institute (HI) recently announced a national pump systems educational initiative called Pump Systems Matter (HI 2004b). This initiative seeks to change owner and operator decision-making on pump systems from a focus on first cost to a focus on life cycle costs, while helping pump users capture significant energy-savings and performance improvements. This is to be accomplished through a variety of measures, including new educational materials and tools aimed at facilities personnel and others, and other outreach activities as defined by the initiative’s steering committee. The Institute has a long-established history as a standards-writing organization, and in recent years has become a principal source of education on pumps and pump systems.

Analysis software to the rescue

At least 70% of pumps are not sized optimally, according to Mike Pemberton, manager, performance services at ITT (www.gouldspumps.com). “I look at it as a process control situation – most automation people’s knowledge of pumps is superficial,” Pemberton says. “Pumps are sized for the maximum flow, but not for optimal control.”

For example, in a typical paper mill designed for 1,000 tons per year, all the equipment is sized for that output, then piped up “like tinkertoys,” Pemberton says. “Along the way, the margins put in by designers, specifiers and suppliers add up to oversized pumps and, to be safe, oversized valves, too. Instead, we need to look at it as a system and use sizing tools that give the effect of the pump size on the valve position.”

Considering the large installed base of poorly sized systems, it would seem that there is not enough appreciation for pump system modeling tools. “People think they can calculate it or use Excel or just do it the same way as last year,” says Trey Walters, P.E., president and chief technology officer, Applied Flow Technology (www.aft.com). “Those methods are inefficient and ineffective. One would think they’d want to do a better engineering job.”

The Hydraulic Institute’s Pump Systems Matter initiative includes a arrangement with Applied Flow Technology to offer a demo version of its Fathom package called the Pump System Improvement Modeling (PSIM) tool, which can be downloaded at www.pumpsystemsmatter.org. “We wanted to make it as simple as possible so people can pick it up and learn to use it quickly and easily,” says Walters. The tool simulates fluid flow in pumping systems and shows pressure drops across piping, valves and equipment using centrifugal and positive-displacement pumps, variable-speed drives, and flow and pressure control valves. You can do what-ifs for impeller trims and calculate energy costs in net present value based on user duration, inflation and interest rate values. “It helps people understand what the effects are of changes,” Walters adds. “You can do a lot of what-ifs much more cheaply than on a real system.

The Department of Energy also offers a package, called the Pumping System Assessment Tool (PSAT), downloadable at http://www.eere.energy.gov/industry/bestpractices/software.html#psat. It uses achievable pump performance data from Hydraulic Institute standards and motor performance data from the MotorMaster+ database to calculate potential energy cost savings. “Just by doing a relatively few field tests, you can tell whether you have the right pump, and it also assesses motor efficiency,” says Greg Romanyshyn, technical director, Hydraulic Institute. The PSAT tool can be downloaded from the DOE Web site at. “The software requires a little bit of background,” says Romanyshyn. The Hydraulic Institute hosts qualification workshops – the next one is in April in Portland, Ore. For more information, visit www.pumps.org.

Parallels in PD

Centrifugal pumps operating away from the best efficiency point (BEP) can waste a lot of energy, but “In the positive-displacement (PD) world, energy efficiency is not generally the prime cost,” says John Petersen, vice president of technical customer service, Viking Pump. “Though the cost of operation can be well over half the life cycle cost, you can’t save a whole lot of energy with a 10-hp pump.”

Oversized PD pumps are rarely a problem because generally, the slower the pump runs the better, due to the viscous drag of the high-viscosity fluids for which they’re used. But too small a discharge pipe can be a problem. “A PD pump will push the fluid through, but at higher pressure and energy costs,” says Petersen. “Pressure can rise until something breaks, so our pumps have an internal pressure relief. If there is another relief valve somewhere in the system, the two reliefs can interact, with one opening, then the other.” A system should have only one relief valve, but if throttling is part of normal operation, there should be a relief valve in the system that routes fluid back to the source.

Most PD pump problems are on the inlet side. Bad suction leads to repairs, downtime and lost production. “First, you can only pull liquid a certain amount. If the suction pipe is improperly sized or too long, you’ll have a problem,” says Petersen. For example, one plant complained about a noisy pump on a 400-foot pipe bringing fuel oil to the boiler. “For convenience, they had put the pump at the boiler end instead of at the tank where it belongs,” he says. “The pump was noisy because it was cavitating, which wastes energy and causes vibration, erosion, premature wear, and seal problems. It can loosen bolts and cause misalignment and piping leaks.”

Inlet conditions can look good, with a short pipe, a positive head at the inlet, and a clean strainer, and still be restricted. “We’ve found all kinds of trash in inlet pipes – cigarette packs, shop rags, even tennis shoes,” Petersen says. “People tend to go to the pump first, but most pump problems are in the system.”