Water-cooled centrifugal chillers for comfort-cooling applications are generally designed for a set of standard conditions promulgated by the Air-Conditioning, Heating and Refrigeration Institute (AHRI). These conditions include a leaving chilled-water temperature (LCHWT) of 44°F and an entering condenser-water temperature (ECWT) of 85°F. But in a process-cooling application, AHRI standard conditions usually don’t apply. The ECWT might remain at 85°F, but the LCHWT might be 65°F or higher.

If it’s to operate efficiently with higher LCHWT, a centrifugal chiller requires certain nonstandard features that might not be present unless specified. To understand their importance, one needs to understand the thermodynamics of “lift” and its relationship to chiller performance. This knowledge facilitates proper chiller selection for process-cooling applications under low-lift conditions.

Understanding lift

Lift (or head pressure) is the difference between condenser refrigerant pressure and the evaporator refrigerant pressure. Using defined pressure/temperature relationships, lift also can be calculated from the LCHWT and the leaving condenser-water temperature. Further, when the LCHWT and condenser-water flow are constant, the ECWT can be used as a proxy for lift. Because most condenser water systems are designed for constant flow, ECWT is the most common metric for lift, and we’ll use it for the purposes of this discussion.

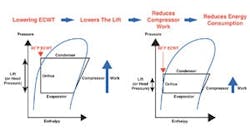

Figure 1. For comfort-cooling, reducing the entering condenser-water temperature leads to lower energy consumption.

In comfort-cooling applications, lower ECWT indicates lower lift, which reduces the compressor work (Figure 1). The relationship can be summarized as: lower ECWT = lower lift = less compressor work = less energy consumption. In comfort-cooling applications, ambient temperatures often allow you to take advantage of an ECWT as low as 50°F (at AHRI conditions).

The ability to use a lower ECWT significantly improves chiller efficiency. In fact, reducing lift achieves greater chiller efficiency gains than can be realized by reducing load. The efficiency improvements from lower lift accrue to both single-chiller and multiple-chiller installations.

Lift in process cooling

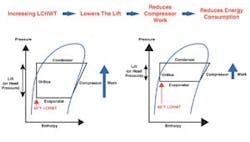

In process-cooling applications, LCHWT is the metric associated with lift - higher LCHWT means lower lift (Figure 2). So, for low-lift process-cooling applications, the formula changes slightly. Now, higher LCHWT = lower lift = less compressor work = lower energy consumption.

Figure 2. For process cooling, raising the leaving chilled-water temperature leads to reduced energy consumption.

But the chiller must be designed to take advantage of higher LCHWT if you want to see effective reduction in compressor work. If the unit is designed properly, you’ll also see significant energy savings because efficiency is mostly a function of lift and only slightly affected by load. These efficiency improvements will be seen in both single-chiller and multiple-chiller installations.

Not every chiller can take advantage of conditions when a high LCHWT is specified. Four design variables affect a centrifugal chiller’s ability to handle low-lift conditions in process-cooling applications:

- The drive design

- The orifice design

- The oil-management system

- The compressor’s aerodynamics

Drive design

It’s not intuitively obvious that electric motor design has anything to do with a chiller’s ability to handle low-lift conditions, but it does. Two motor choices for centrifugal chillers are a refrigerant-cooled type (hermetic-drive) and the air-cooled type (open-drive).

A hermetic-drive motor is located inside a refrigerant-filled motor cavity. Unfortunately, this is a bad place for it to be under low-lift conditions. The head pressure on a hermetic-drive motor must always be high enough to ensure an adequate refrigerant flow through the motor cavity. Without sufficient flow, current draw can overheat the motor windings, and a high motor temperature will shut down the chiller. For that reason, chillers with a hermetic-drive motor must maintain a greater pressure differential between the evaporator and the condenser to ensure adequate motor cooling. Artificially limiting the lift reduction is a common way to ensure sufficient pressure differential in hermetic-drive chillers and limiting lift reduction increase the compressor’s energy consumption.

An open-drive motor, on the other hand, is located outside the refrigerant circuit. Therefore, it can be air-cooled or water-cooled. It doesn’t depend on refrigerant flow for cooling and is unaffected by changes in refrigerant flow during low-lift conditions.

Orifice design

The orifice is the chiller component that produces a refrigerant pressure drop between the condenser and the evaporator. There are two orifice options: fixed and variable. It’s difficult for a chiller with a fixed orifice to perform efficiently under low-lift conditions at full loads. The fixed orifice is sized for the high head pressure that exists at design-lift conditions. As a result, fixed orifices are simply not large enough to allow the required refrigerant flow at low-pressure conditions.

The variable-orifice design, however, is more accommodating. A variable orifice modulates automatically to maintain proper refrigerant flow, taking into account the pressure drop it introduces. At design-lift conditions, the variable orifice is partially closed. At low-lift conditions, it opens to allow greater refrigerant flow rate. This feature is especially important for multiple-chiller plants in which additional chillers and associated auxiliaries, pumps and towers must operate to meet building demand. Without a variable orifice, you might resort to running more chillers and more auxiliaries than needed because the chillers are unable to load up properly. This is an extremely inefficient way to operate a chiller plant.

To avoid the full-load problem of fixed-orifice chillers under low-lift conditions, some chiller manufacturers maintain a high minimum ECWT, as high as 75°F. But this strategy for increasing lift (head pressure) to maintain chiller stability sacrifices chiller efficiency when low-lift conditions are available to slash operating costs. The only way to achieve both full-load cooling capacity under low-lift conditions and off-design energy performance is to use a variable orifice as a refrigerant-metering device.

Oil-management system

Low-lift conditions also affect a chiller’s oil-management system. Under low-lift conditions, hermetic chillers can lose oil through the motor bearings and refrigerant-gas seals at a faster rate. When this happens, large amounts of oil enter the refrigerant circuit and migrate to the evaporator. Normally, excess oil resides in the compressor’s oil sump. But if oil is in the evaporator instead, the chiller can shut down on a low-oil-pressure safety.

In addition, the excess oil in a flooded evaporator migrates to the top layer of tubes, where the best heat transfer (refrigerant boiling) is supposed to occur. When oil displaces refrigerant in this area, heat transfer and chiller efficiency suffer significantly.

Open-drive centrifugal chillers can use an oil-management system that makes oil loss a relatively minor issue at low-lift conditions. An oil-eduction system can separate oil from the refrigerant in the evaporator and return it to the oil sump. With this system, more oil stays in the sump, permitting the chiller to operate effectively at low-lift conditions.

Compressor aerodynamics

A centrifugal chiller’s compressor design also is critical to low-lift performance. That’s because a centrifugal compressor operates most efficiently when the impeller tip speed is optimized for the application. In a direct-drive unit, the only way to adjust tip speed is by changing the impeller size. Because there are relatively few impeller sizes from which to choose, compressor tuning is constrained and performance suffers accordingly.

On the other hand, in a gear-drive compressor, tip speed is a function of impeller size and gear ratio. With multiple impeller options and gear ratios for each compressor size, it’s easier to select a gear-drive compressor that will match the low-lift application’s requirements most efficiently.

Centrifugal chillers that can adapt to low-lift conditions, where high LCHWT reduces head pressure, save energy in many process-cooling applications. To take advantage of low-lift conditions, the chiller should have an open-drive design to ensure proper motor cooling, a variable orifice to ensure proper refrigerant flow, an oil-eduction system to return oil to the sump, and a gear drive to optimize impeller tip speed.

A chiller equipped with these four critical design features can deliver superior performance in low-lift conditions and provide significant energy savings in a range of process-cooling applications.

Tony Doyon is senior program manager at Johnson Controls Inc. in York, Pa. Contact him at [email protected] and (613) 225-8045.