Best practices to extend bearing life, cost savings and uptime

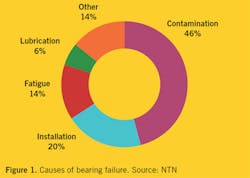

Mounting, lubrication, and contamination account for nearly three-quarters of bearing failures. Improper mounting accounts for approximately 20 percent, while lubrication and contamination account for approximately 52 percent (see Figure 1). Bearing types and applications vary; and therefore, bearing type, mounting method, and lubrication recommendations will vary.

Mounting

It is important that the fit between the rotating component and associated bearing ring are adequate for the application. For unmounted radial bearing applications, the shaft is usually rotating, so a tight fit is required. This means the shaft outside diameter (OD) is slightly larger than the bearing bore.

If the fit is too loose, the shaft could slip in the inner ring. This will cause wear on the bearing bore and could increase the temperature to an unsafe level. If the fit is too tight, this could cause stress in the inner ring, which could lead to failure. While a cracked inner ring (see Figure 2) may not seem like a serious issue in the beginning, it can lead to more significant problems.

Several methods are available to properly mount the straight bore bearing onto the larger shaft. An arbor press or driver kit can be used for smaller bearings. Due to the forces needed, there is a higher possibility of damaging the bearing. It is also advised that any force be applied to the appropriate mating component, so as not to damage the bearing raceways.

An induction heater is the easiest method (see Figure 3). The modern bearing heaters have controls to prevent overheating and to ensure the bearing is not damaged during installation. The heater works on the principle that metal expands when heated; by making the bore larger, little to no force is needed during installation onto the shaft.

As a general rule of thumb, a bearing should be heated to about 100°F (38°C) over ambient temperature to ensure that proper mounting is achieved. For larger bearings or longer shafts, it may be necessary to heat the inner ring higher, but care should be taken to not surpass the temperature limit of the bearing material. Typical bearings are rated to about 248°F (120°C).

Tapered bore bearings require a tapered shaft, or more commonly, a tapered sleeve between the bearing and the shaft; these bearings are installed using the drive-up method. Manual and hydraulic methods are available for driving the bearing up the tapered sleeve. The proper drive up is achieved by measuring radial internal clearance, axial movement, or degrees of locknut rotation.

Finally, ball bearing mounted units typically do not have a press fit to the shaft. The bearing bore has a positive tolerance and can be slid onto the shaft. For this reason, they have a locking mechanism built into the inner ring. They are offered in set screw, eccentric collar, and tapered bore adapter.

The set screw locking contains two set screws that are driven into the shaft. The eccentric collar has an offset cam with a set screw to secure the collar. The collar should always be tightened in the direction of shaft rotation. For both of these mounting styles, tightening the set screws to the proper torque is important. If they are undertightened, they could back out or the shaft could slip. If they are overtightened, they could add stress to the inner ring, which could lead to cracking as well as shaft surface damage.

Lubrication

Lubrication is a critical factor in all bearings, especially ones that need to be relubricated during operation. Bearings typically function best when only about one-third of the internal effective space is filled. The effective space is the space between the rolling element path and the seals.

Grease is made of a base oil, thickener, and additives. The oil is what lubricates the bearing. By filling only one-third of the effective space, this provides room to push any unnecessary lubricant aside. Having too much or too little lubricant can cause the bearing temperature to rise.

- Read "Bearings are not boring"

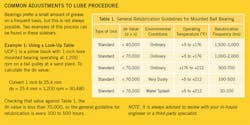

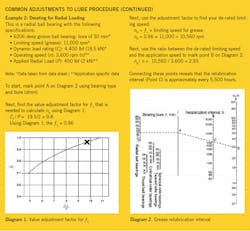

To determine how much and how often to relubricate a bearing, follow the manufacturer’s guidelines, or consult your in-house engineer or a third-party specialist. Provide details on the bearing used (type and size) and application (speed, temperature, contaminants, lubricant), then a preventative maintenance procedure can be determined. Most often, the initial procedure, which is based on theory, will be adjusted over time based on experience (see sidebars).

An alternative to consider for some applications would be a solid lubricant. This lube type eliminates the grease-purge, particle wear, and fluid wear commonly associated with food-grade applications. From a reliability standpoint, solid lube extends the life of a standard bearing insert exponentially. For dry applications where washdown is not required, solid lube is available to provide protection from dry particle wear, and the inserts are interchangeable and adaptable to numerous housing configurations.

The bearings with solid grease may be assembled by a “shrink fit” technique. However, be absolutely sure that the maximum heating temperature does not exceed 212°F (100°C), the heating time is shorter than two hours, and the bearing does not turn during the shrink fit process.

Following these best practices will help extend bearing life as well as cost savings and uptime. Be sure to engage your in-house engineer or a third-party specialist for best optimization of these assets.

Brian Lawrenz is product sales manager of power transmission, bearings, and material handling for Motion Industries. He joined the company in 2017 and has 20 years of industry experience, with a special focus on power transmission. He holds a degree in Industrial Distribution from Texas A&M University.

Jennifer Wagoner is senior applications engineer at NTN Americas and has been in the bearing industry for 20 years. She began her career in 2000 with NTN Americas as an application engineer, and took on her current role in 2014 to educate and train end users about bearings in order to make their job easier, and thoroughly enjoys working in heavy industry.