No matter the size, any production system will have at least one motor to provide the power—and with proper attention, that motor’s efficiency plays its part in a plant’s smooth operation. Consider the current motor population in your facility. The typical facility has motors from multiple manufacturers with various applications, horsepower, enclosures, and mountings. Let’s explore some strategies to extend motor life and reduce unplanned failures.

1. Motor specifications / standardization

First, let’s address motor specifications and standardization. This discussion will focus on ac, three-phase, general purpose motors, which comprise the most common motor type in industrial manufacturing facilities.

The basic characteristics for general purpose motor selection are:

- manufacturer

- horsepower

- revolutions per minute (rpm)

- frame size

- mounting

- ambient temperature

- enclosure/environment

- variable frequency drive (VFD) ratings

- any special requirements.

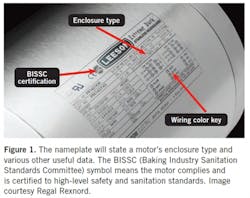

For standardization, we will concentrate on manufacturer, enclosure type, and VFD ratings. The other characteristics are determined by the application, and various motor versions should be available to meet the requirements.

Choose a quality motor manufacturer. Choose a high-quality motor manufacturer that you trust and is well known for long-life products, availability, and customer support. A fair number of high-quality manufacturers meet these criteria. You will also find a wide variety of motor configurations to meet your needs. Note that with the current premium efficiency standards, some manufacturers consolidated their offerings when they redesigned their motors to meet the new requirements. Some low-volume motor configurations may no longer be available and may require changing the load mounting to meet the new standard motors.

Choose motor enclosures for the plant environment. General purpose motors come in enclosures ranging from open drip-proof (ODP) to severe duty, such as the IEEE 841 specification. The ODP motor allows air from the environment to pass directly through its windings for cooling. If your plant environment is dusty, dirty, wet, or outdoors, the ODP motor will not be the best selection for long life.

The next motor enclosures available are the totally enclosed fan-cooled (TEFC) or totally enclosed nonventilated (TENV) motor. The TEFC motor uses an integral fan to move air across the motor’s exterior surface to cool. By contrast, the TENV motor depends on the enclosure surface area to dissipate motor heat into the ambient air. These motors offer better protection from the environment for clean to mid-range dirty environments.

With their labyrinth shaft seals, interior coatings, and exterior coatings, severe duty motors are designed to add a higher level of protection from harsher environments. The IEEE 841 specification motor follows one of the highest standards for environmental protection. The IEEE 841 also includes enhanced rotor balance and foot flatness standards that provide less vibration and lengthen life when installed correctly.

An additional enclosure type—this one focused on the food industry—is the washdown motor. Washdown motors include three versions: white epoxy paint (IP55), all-stainless steel (IP56), and finally, an all-stainless-steel version with the motor windings encapsulated in epoxy for additional protection (up to IP69 — see Figure 2). Washdown motors provide optimal protection in a wet washdown food environment.

A customer of ours, a food processing facility, was experiencing TEFC motor failures on a bottle filler conveyor every three months. The motor was subject to daily washdown and was exposed to water when running. The facility installed an all-stainless-steel motor with encapsulated windings, and the motor has been running for more than two years without failure.

The motor manufacturer’s warranty typically varies with the enclosure type. ODP motors have the lowest warranty at 12–18 months, while the IEEE 841 has the highest warranty at 60 months. The washdown motors are similar from 12–18 months for the lower end, up to all-stainless versions with a 36-month warranty.

Ensure motors meet VFD requirements. Motors’ capabilities vary in running with a variable frequency drive (VFD). If you use a VFD to control a motor’s speed, there are three main considerations to selecting the right motor:

- Is the motor rated for operation on a VFD?

- What is the load type?

- What is the desired speed range?

Motor VFD capabilities vary. Some general purpose ac motors are not rated for operation with a VFD, and the motor winding insulation is not suited for the electrical characteristics of the VFD output signal. (If the motor’s VFD rating/capability isn’t immediately clear, consult the manufacturer’s information or an electrical specialist to confirm.)

The speed range capability on a VFD-rated motor is generally rated by the load type. The load is classified by variable-torque (VT)/normal-duty (ND) load or constant-torque (CT)/heavy-duty (HD) load. Normal-duty loads are typically centrifugal pumps and fans. Heavy-duty loads include conveyors, bucket elevators, positive displacement pumps, and other loads.

Motor manufacturers typically offer an ND/VT rating and an HD/CT motor rating. This rating is expressed in ranges that indicate the VFD range capability from the nameplate rpm divided by the rating. For instance, if a 1,750 rpm motor has a constant-torque/HD rating of 2:1, it is rated for 1,750 ÷ 2 or a range of 875-1,750 rpm. Running a motor below this speed rating may not dissipate heat properly and result in the motor overheating.

There are VFD-rated motors that range up to 2000:1 for VFD operation. The 2000:1 rated motors provide full output torque from zero speed to the nameplate rpm. A closed-loop vector VFD with motor feedback may be required to run the motor at zero speed and wide speed range.

Also, be cautious running a motor over the nameplate rpm. With a VFD, the motor torque output capability is reduced as the motor speed increases above the nameplate rpm.

Motor cost is always a factor when selecting the right motor. Consider that the initial motor cost is a tiny percentage of the overall cost of the motor’s operation over its life. When you factor in the costs of electrical power, installation, maintenance, preventive maintenance, and production, the initial purchase cost is a very small percentage. For instance, selecting the severe duty motor for your application may initially cost more than a TEFC motor but results in a longer reliable life for your system.

2. Motor installation and maintenance best practices

The next step in assuring motor reliability is using best practices when installing and maintaining motors. Proper installation starts with correct handling of the motor when received. Lift the motor by the lifting points, such as the lifting eye or feet/body. Check the shaft to ensure it rotates without rubbing.

The Big Four factors affecting motor health

Testing and diagnostic solutions for industrial motor heath

What’s new in the ANSI/EASA AR100-2020 motor repair standard?

Foot mounting should be on a ridged surface and securely fastened. Shims should be used to properly level and align the motor to the load if needed. Laser alignment will help provide the best mounting practice to ensure minimum vibration for coupled loads. Confirm motor rotation before coupling to the load to prevent damage if the load is designed to rotate only in a specific direction.

For V-belt-driven loads, mount the pulley close to the motor housing. Adjust the belt tension as required but not too tightly; excessive tension will result in premature bearing failure. Some applications requiring high belt tension need a roller bearing on the output shaft to ensure long bearing life.

C-face motor mounting to a reducer must be carefully installed to avoid excess pressure on the motor shaft. Forcing the motor into the C-face mounting may result in premature bearing failure.

The electrical connection needs the correct wiring diagram posted next to it, showing the voltage, required connection torque, and proper grounding methods. Suitable motor protection must also be used, including proper fusing and overload protection per NEC or local code requirements. Some washdown stainless encapsulated motors come with silicone wire nuts or other features to protect connections from water.

Make sure drain plugs are removed from the lowest opening in the motor. A “tee” drain can be added to prevent splashing water from entering that hole. Drains are designed to let water and condensation escape from the motor.

3. Preventive maintenance and predictive maintenance

Now that the motor is installed and running, regular preventive maintenance and predictive maintenance will keep the motor running for long life.

Motor lubrication requirements vary based on the motor type, rpm, running hours, and environment. Some motors are pre-lubed for life, so lubrication is not required. Other motors will require scheduled lubrication. Take care to use grease that is compatible with the original factory grease. Never overlubricate, which will result in premature motor failure.

Check the motor manufacturer’s maintenance guidelines for lubrication type, amount, and regreasing intervals. Always wipe off grease fittings before greasing, open purge fittings if equipped and wipe off the grease fitting again after installing lubricant.

Ensure motors are free from accumulated dust, dirt, and other contaminants in your environment. A coating of contaminants on the motor will insulate it, causing higher internal temperatures that could reduce motor life.

Routinely check the motor and equipment condition. Listen for abnormal sounds and check for excessive temperature or vibration. Use handheld thermal instruments and vibration monitors for spot-checking. Set up a schedule to check the condition of running motors—especially for critical ones. Track your readings to establish baselines and trends.

Service providers can do routine analysis on critical motors in your facility. These services can include vibration monitoring and thermal image scans. Over time, the scheduled readings will provide a base reading and subsequent condition monitoring to help predict when motors need to be serviced or replaced. Preventive/predictive maintenance will help you schedule the service or replacement and reduce the chance of an unplanned failure and downtime.

Technology has evolved to monitor critical motors and/or all motors continuously. Sensors, monitoring equipment, and software are available for real-time observing and recording a motor’s condition. A database of readings will be used to build trends of motor condition and allow you to decide when to service or replace motors. The Industrial Internet of Things (IIoT) is the hardware/software strategy to bring predictive maintenance in a high-level view and manage your facility’s equipment operation. The system can be cloud-based and allow review from anywhere. It can also alert the appropriate persons when thresholds are reached, and it is time for scheduled actions.

Best reliable motors

Motor reliability is vital to maintaining efficient and profitable plant operations. Addressing the various steps to achieve optimum performance and reliability is key.

Consider the characteristics and standards that determine the best reliable motors in your facility. Choose a high-quality manufacturer and match the motor features to the environment and application. Compare the motor cost to potential long-term savings.

Proper Installation techniques and routine maintenance are critical to the reliability and life of your motors. Consider implementing the necessary training and best practices for your motor installation needs.

Finally, preventive and predictive maintenance are cost-effective ways to maintain and ensure long, reliable motor life. These strategies will provide return on your investment with unplanned downtime cost reduction and greater line uptime.

Engaging a third party can help with any step or even the whole journey in your reliable motor planning and implementation. From motor selection/standardization and motor maintenance practices to preventive/predictive maintenance strategies, trained professionals can help you build the most reliable solution.

This story originally appeared in the June 2022 issue of Plant Services. Subscribe to Plant Services here.

An electrical specialist at Motion, Tim Tiebert has been working in the automation and engineering field for more than 40 years, with the last 25 years at Kaman Distribution and 15 years as a project and plant engineer in the food industry. His expertise covers automation, industrial control, power transmission, electrical engineering, and control systems design.For more information, visit Motion.com/plantservices or join us behind the scenes in a production facility via this video to find out how the washdown motor in Figure 2 is manufactured.