Electric motor noise: How to identify the cause and implement a solution

Determining the source of noise in an electric motor is often more challenging than correcting it. A methodical investigative approach, however, can narrow the possibilities and make it easier to resolve the issue—with one caveat. If the noise is due to something in the motor design (e.g., a manufacturing defect or anomaly), a solution may be impossible or impractical. With that in mind, let’s review the primary sources of noise in electric motors—magnetic, mechanical, and windage—as well as their causes and ways to reduce or eliminate them.

Magnetic noise

(Note: All noise originates with mechanical forces that transmit waves of pressure through air, liquids, or solid materials. Noise frequency components within the range of human hearing generally fall between 20 Hz and 20 kHz.) Magnetic noise in a motor (a.k.a. “electromagnetic” or “electrical” noise) results from mechanical forces (e.g., pressure) generated by the attraction and repulsion of magnetized parts in its alternating magnetic field. The alternating magnetic field excites vibration and noise at twice line frequency (e.g., hum) but only while the motor is energized. (Tip: If the noise immediately stops when the power is removed, its source is magnetic.)

Magnetic noise is typically the second largest source of noise for two- and four-pole motors (windage is first) and can be the main one for motors with six or more poles. This is primarily because slow-speed cores have less stator back-iron depth than higher speed cores with fewer poles (see Figure 1), making them more susceptible to deformation and resulting in greater amplitude vibration from smaller forces. Slower speed motors with six or more poles are prone to higher noise levels due to smaller air gaps and the effects of eccentricity from out-of-tolerance bearing and housing fits.

If magnetic noise is its main source, the overall motor noise tends to increase when load is applied (see Table 1). Usually, the difference in overall noise level at no load and full load is small for two- and four-pole motors, but it can be significant for motors with six or more poles.

Motor designers manage magnetic noise by making the air gap as large as possible (while maintaining acceptable power factor). They also can reduce the magnetic forces arising from air gap variations and generally improve power factor by using a longer core to decrease air gap flux density.

Another consideration is that closed slots never cause an increase in magnetic noise, which explains why designers prefer closed-slot rotors. They also favor semi-closed slots with minimal openings for random-wound stators, even though wider slot openings would make windings easier to insert.

Slip noise. A related form of magnetic noise is slip noise. This relatively low-volume, low-frequency beating of higher frequency components may be objectionable because it is intermittent. Being a function of slip, it is more noticeable under load, with the frequency varying directly with slip. Causes may include an open rotor bar or end ring, but slip noise is usually associated with a defect in the uniformity of the squirrel-cage rotor, the remedy for which is a new rotor.

Skewing. Skewing of the rotor slots reduces magnetic noise, but there’s no consensus on the optimum amount or even an accurate way to calculate its effect on the noise produced. A common suggestion is to skew the rotor, at least one rotor or stator slot (whichever has fewer slots). Anything less will not reduce magnetic noise appreciably, and larger skews usually degrade motor performance.

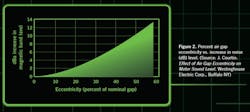

Unequal air gap. An unequal air gap causes unbalanced magnetic pull with stronger magnetic forces in the direction of minimum air gap (see Figure 2). This can deform the stator, rotor and frame while generating electromagnetic noise. Running the motor at reduced voltage is a simple diagnostic tool. For example, if the motor is noisy at full voltage but sounds fine at half of rated voltage, focus on the air gap and such issues as mis-machined housing or an eccentric rotor.

Causes of an unequal air gap are:

- Eccentric rotor

- Eccentric stator

- Bent shaft

- Shaft journals machined out of concentricity with rotor body

- Bearing housings (or sleeve bearings) not concentric

- End bracket to stator fit not concentric

- Distorted frame

Manufacturing variations affect the magnetic noise of slower speed motors more than they do two-pole motors. That’s because motors with four or more poles have a much smaller air gap than two-pole motors, making the margin for error much smaller for them. For example, the air gap for a six-pole motor with a 22-inch (560-mm) OD stator could be 0.022 inches (0.55-mm), while that of a two-pole motor with same stator dimensions could be 0.055 inches (1.4 mm).

Mechanical noise

The sources of mechanical noise in a motor include a loose stator core; worn, damaged or poorly lubricated bearings; and rubbing of internal components. Additionally, any structural part of the motor that is excited at its natural frequency can become the source of airborne noise.

Loose stator core. A stator core that is loose in the frame will cause a buzzing noise. On motors with rolled steel frames, it’s easy to check for this by tapping the outside of the frame (shell) with a mallet while the motor is running. If tapping deforms the frame-to-core fit, the noise level will change or may even cease. Strictly speaking, the source of this noise is magnetic, so the noise will also cease when the power is removed.

Bearings. Bearings are a frequent source of mechanical noise in motors. Excessively noisy rolling element bearings, for example, may be traceable to nonuniform balls or rollers, rattling ball or roller retainers, poor surface finish, or eccentricity. Besides impact noise, these conditions can result in resonance excitation of bearing housings, air deflectors (baffles) and other parts that radiate noise efficiently.

Some sources of bearing noise are distinct and easy to identify. For instance:

- Brinelling produces a low-pitched noise.

- Dirt in the bearings causes a shrill noise.

- Ball or roller skidding at low temperatures with insufficient lubrication produces a high-frequency noise.

- An intermittent popping noise is often due to the grease.

Noise in the 100 to 300 Hz frequency range is characteristic of rolling element bearings and may be due to the passage of the balls or rollers. Usually, this noise is low amplitude and not physically detrimental unless it excites the natural frequencies of other motor parts and causes damaging vibration.

One way to reduce and dampen bearing noise is to preload the bearings axially with a wavy-spring (wave) washer. Usually, the washer exerts a force on the outer race of an axially free ball bearing (typically the non-drive end) to eliminate the internal clearance between it and the locked bearing. This causes each ball to follow the same raceway path in each bearing, which decreases noise from balls rattling within the raceway and cage, while reducing high-frequency vibration. Bearing preload also improves dynamic balance by eliminating bearing looseness. Too much bearing preload, however, produces low-frequency noise and can possibly overheat the bearings.

Friction noise in a bearing arises from insufficient lubrication. This allows rapid intermittent contact between two sliding surfaces, which produces high impact vibration. The noise at the point of contact is high frequency and sounds like hissing air. When transmitted to a resonant part inside the motor, impact vibration makes screechy noises.

Rubbing of internal components. Besides worn or damaged bearings, other sources of mechanical noise within the motor include physical rubbing of the external fan and cover, the internal fan and air deflectors, and the rotor and stator. Correction of these issues requires locating fans properly and restoring rotor-stator concentricity to proper tolerances.

Airborne noise. As mentioned earlier, any structural part of a motor may become a source of airborne noise if it is excited with sufficient energy at its natural frequency. For example, rotational unbalance itself may not emit audible airborne noise, but it may act as an energy source for vibration. The vibration is then transmitted through the support structure and converted to airborne sound waves at the resonant component, making the vibrating part appear to be the noise source.

If an air deflector, drip cover, or similar component is vibrating, application of noise damping material often can change vibratory motion into heat energy using the internal friction of the material. An example of this would be the use of room temperature vulcanizing RTV silicone between an air deflector and an end bracket to reduce noise.

Porous, sound-absorbing materials also can reduce emissions of airborne noise created within the motor by converting the energy from sound waves entering their pores to heat energy. The absorption capability of these materials increases with their density, thickness, and tightness or pore structure. If possible, the barrier should completely enclose the source. A potential drawback of sound-absorbing material is that it may restrict airflow or heat transfer, thus increasing motor temperature.

Windage noise

Windage noise, which typically accounts for most of the noise from an electric motor, is most prevalent in high-speed (e.g., two- and four-pole) motors. Since it is caused by turbulent airflow at obstructions near the rotating part that moves air, the best way to reduce it is to minimize the obstructions. Windage noise differs from most motor noise sources because it originates in the airstream rather than in the motor parts. Usually, it is broadband noise (wide range of frequencies) with essentially no significant pure-tone (sinusoidal waveform) components.

Most of the windage noise of larger open enclosure motors comes from the fan action of the rotor bars, not from the cooling fans or fins. Because of this, reducing cooling fan diameter probably won’t result in much noise reduction, but it could significantly reduce cooling airflow.

Large open motors with radial vent ducts through the rotor and stator may produce irritating pure-tone components of airflow noise, typically at a frequency above 1,000 Hz. Often termed the siren effect, this noise is due to sudden interruptions of the airflow exiting the rotor’s radial ducts. Offsetting the rotor ducts with respect to stator ducts can help decrease the volume of this noise.

On totally enclosed fan-cooled (TEFC) motors, decreasing an external fan diameter or changing the type of fan are good ways to reduce noise, especially in unidirectional applications. But reducing a fan or vent path will make the motor run hotter, shortening the life of its lubricant and winding. Increasing the clearance between the fan and stationary parts or spacing the fan blades asymmetrically can also reduce the fan-blade-frequency noise of a TEFC motor.

To conclude, air flowing around or against surfaces produces turbulence, a potential source of objectionable noise. From an airflow design perspective, here are some considerations manufacturers use for avoiding windage noise issues:

- Eliminate sharp edges and burrs on all parts in contact with the airstream.

- Minimize abrupt changes in airflow direction.

- Keep boundary surfaces smooth.

- Provide gradual changes in airflow path cross section.