In this article:

- Enabling a more flexible production facility

- Conserving floor space, expanding modularity

- Cabinet-free technology enhances reliability

Consumer habits are changing faster than ever. New or modified products must be brought to market at an increasing rate. This poses a challenge to manufacturers and to plant engineering as a whole: Today’s machines must be modular and scalable, incorporating technologies that are intelligent and giving plant engineering and operations the freedom to make changes as their business changes.

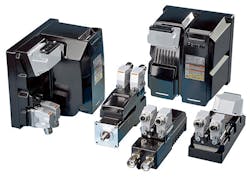

Figure 4. New innovative machine designs with minimal floor space usage are possible with cabinet-free drive technology.

This is a key reason as to why intelligent drive and control systems are in demand: They feature technology that is compact, highly efficient, easy to integrate and, to save the most space, ideally cabinet-free. The first drive technologies that could be considered “cabinet-free” were servo motors with drives integrated into the motor housing—technology that’s more than a decade old at this point.

Since then, drive and control suppliers have been expanding their portfolios to give both machine builders and the end-user manufacturing community greater choices. In essence, this “frees” manufacturers from having to configure their production systems and process flow around the size and location of machine control cabinets.

Enabling a more flexible production facility

Across many manufacturing segments, the demand for flexible automation systems is very high. Plant operators don’t necessarily want new machines with large footprints that occupy valuable production space and limit access with large control enclosures. Nor do they desire technology and equipment designs that would hamper adding on new process equipment, transport conveyors or automation systems in response to changing market needs.

Traditional, cabinet-centric servo drive architectures can have these kinds of limitations especially since the electric servo use in machines continues to increase. Consider a typical nine-axis machine. Each servo motor has a separate power cable and feedback cable running the length of the machine all the way back to the drives in the cabinet. Any time the machine’s footprint needs to be adjusted, or additional manufacturing modules need to be added, the machine may need extensive rewiring of control cabinets to accommodate such machinery changes.

This article is part of our monthly Automation Zone column. Read more from our monthly Automation Zone series.

In a cabinet-free design, the drives are integrated into the servo motors (see Figure 1). Many models of this technology use a single cable that combines power, control voltage, and communications into one. Furthermore, this equipment can be daisy-chained, so that much shorter and simpler connections are needed to implement power, control voltage, and communications to all the drives from the machine’s controller and small power cabinet.

Figure 1. In a cabinet-free design, the drives are integrated into the servo motors.

This flexibility and openness to modularity are essential to the way manufacturers seek to configure their production systems for today’s markets (see Figure 2). This is particularly valuable for manufacturers who seek to create a manufacturing platform that allows them to efficiently produce highly customized products or versions of products in small batches, besides high volume runs with tens of thousands of the same product.

Conserving floor space, expanding modularity

Plant production space is valuable, which is why end users demand more compact machines in order to increase their production capacities within an existing space. Separate control cabinets take up a lot of space and limit access to the manufacturing process. For this reason, many drive and controls suppliers now offer broadened portfolios of cabinet-free technology (see Figure 3). These include standard motor-integrated servo drives, which have expanded power options ranging from 11 kW to 0.4 kW.

Figure 3. Motor integrated technology can dramatically reduce electric enclosure size and enable innovative production machine designs with full access.

These portfolios also include what are commonly called “near-motor” servo drives: drive electronics that can be mounted on machine frames, separate but close to the servo motor, in order to maximize the flexible options that machine designers seek. For example, one packaging machine designer mounted the near-motor servo drives on top of the machine and connected them to motors below that powered a series of delta robots. The drives are easily accessible for maintenance purposes, and the entire design provides a compact and intelligent use of production floor space.

Cabinet-free technology suppliers recently began offering complete decentralized power supply and mains modules. Now machine manufacturers can integrate all drive components directly onto the machine without the need for a control cabinet. The mains module includes a mains filter, mains regulator, and even the mains protection in one device, often incorporating regenerative power technologies.

With this technology, all production machines and modules can be directly connected to the line power supply without requiring cabling and connecting back to a control cabinet, potentially reducing machine assembly wiring by 90 percent.

Cabinet-free technology enhances reliability

One common way plant management assesses the performance of their production systems is through measuring Overall Equipment Effectiveness (OEE), which is a measure of how well a manufacturing asset works compared to its full potential. A key element of that measurement is the system’s availability and uptime.

One of the advantages of the latest generation of motor-integrated servo drives is how rugged and reliable they are; they have been engineered to function flawlessly for many years in the open conditions of the manufacturing floor, within machine space and even mounted on moving armatures and actuators (see Figure 4).

Figure 2. Cabinet-free technology provides benefits across all aspects of the manufacturing value chain.

In many cases, this can make them even more reliable than servo platforms with the drives located in control cabinets. Most cabinet-based drives are rated to IP-20 because it’s assumed that the closed, air-conditioned cabinet environment will be stable and not require higher levels of protection. However, in some production environments, like woodworking plants, composites production or plants producing ceramic products, a high level of dust can be present. This dust can or will eventually infiltrate into the cabinet anytime through conduits and if it is opened, risking damage to electronics components, therefore disrupting production.

Many motor-integrated servo drives are rated IP-65 with all electronics fully enclosed, making them much more reliable and able to withstand the more demanding conditions present on many manufacturing floors. This makes them a valuable option for a wider range of manufacturing environments.

The reliability advantage cabinet-free technology offers extends to long-term operations. Fewer components and connection points of cabinet-free solutions mean less complexity to troubleshoot. The intelligence and connectivity built into the drives offer more diagnostics that hone in on the nature and location of the problem.

With fewer connections and components, less machine downtime is possible, primarily because there is less to troubleshoot while the machine is out of production. This speeds up decision time to replace a component and consequently reduces machine downtime. Thanks to closed-loop redundant communication, pinpointing a problem with an axis is extremely quick. And because cabinet-free machine design makes the axis easily accessible, replacing it is as simple as removing two connectors and mounting screws, replacing the axis, and getting it back into production. And by reducing electric cabinet size and components in cabinets, less AC equipment must be maintained.

Conclusion

Cabinet-free drive technology offers a wider range of possibilities for modularized machine designs, in line with the needs of today’s manufacturers. Machine builders can preassemble modules and then connect them to one another without any further changes to the cabinet reducing installation time to start of production. More powerful technologies with better IP protection ratings make components smaller, more intelligent, more mobile and reliable. Ethernet connectivity, along with standard protocols and safety functions, allows for all of these devices to be located directly on the machine. The benefits for plant management and manufacturers range from simply reducing wiring to providing significant cost savings across the complete manufacturing value chain.