Electric motors are the most common machines in any manufacturing plant. They’re reliable, efficient and can drive almost any kind of load. Treat them correctly and they’ll reward you with long life. To maximize the chances of reaching that long life, you should have an effective preventive and predictive maintenance program in place that’s based on all the probable motor failure modes. Often, failure modes and effects analysis (FMEA) or reliability-centered maintenance (RCM) can serve that purpose because both technologies require intimate knowledge of how things can break down.

Let’s take a closer look at electric motor failure to examine the stresses on the motor, the most common failure modes and some of the causes of those failure modes. Then, let’s look at some ways to either mitigate the failure or to detect an incipient failure.

Motor life

They can last a long time, but motor death usually has nothing to do with aging. Many questions arise before you can decide when that life is over: How do you define the end of motor life? Does bearing failure constitute the end of life? Does having to rewind the stator define it? How about having to scrap the motor because it’s beyond repair? Or, is it more sensible to replace it so you can capture the energy savings that higher-efficiency motors provide?

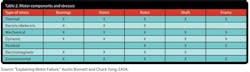

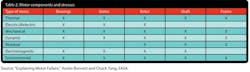

Fortunately, you can use standardized tables to help predict motor life (Table 1). Factors that affect motor life are numerous. They include:

- Motor design

- Materials of construction

- PM/PdM effectiveness

- Insulation class

- Bearing type and quality

- Enclosure type

- Quality of construction

- Operating environment

- Load characteristics

The motor is one part of a system that includes its power supply, mounting, coupling and driven equipment. The environment includes ambient temperature, airborne contamination in the vicinity (moisture, corrosive fumes), ambient shock and vibration, etc. It’s a combination of stresses acting on the bearings, stator, rotor, shaft and frame that causes most motor failures.

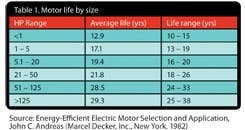

Motor stress

Table 2 shows the major stresses acting on the five primary motor components. A number of failure mechanisms can cause the same component to fail with a common mode and failure pattern. For example, improper voltage, overloading, blocked ventilation, excessive cycling and excessive heat all can produce the same type of winding failure. Many motor failure studies tell us that the bearings are the most common cause of failure. Next is electrical failure, followed by mechanical failure (see sidebar).

Bearing modes

Bearing failures have many causes, but they can be tied to installation, cleanliness, lubrication or load. The first reliability rule regarding bearing installation is proper selection for the application.

Type, load rating, quality grade and shielding are some of the factors to consider. Bearing installation problems often are a question of workmanship. Proper tools, proper procedures and a clean work environment mitigate bearing failures.

Inattention to cleanliness is a major cause of bearing failure. Contamination can enter the bearing in a number of ways. A dirty installation environment is a prime contributor. Contamination also enters through poor lubrication practices such as not cleaning the grease fitting when applying grease.

Lubrication ranks with contamination as a contributor to bearing failure. Factors to monitor include using the correct grease or oil, possible lubricant mixing that causes incompatibility problems, and extended lubrication intervals. Too much grease also can be a problem. Not allowing the bearing to relieve the excess grease through the drain plug is one of the more common bad practices.

A number of issues contribute to excess bearing loading:

- Wrong coupling type or installation

- Dynamic overloading (balance, misalignment)

- Belt, sheave or insert wear

- Belt misalignment

- Incorrect belt tension

- Static loading

- Poor workmanship

- Defective bearing housings

Some common measures you can institute to mitigate bearing failures include:

- Visual inspection

- Vibration monitoring, including bearing-specific techniques (shock pulse, ultrasound and others)

- Precision shaft alignment

- Belt alignment and tensioning

- Lubrication programs that follow best practices

- Proper tools, environment and training for technicians

Because bearing failure is the most common problem for electric motors, eliminating bearing problems can prevent 25% to 80% of motor failures.

Electrical modes

Excessive heat in the winding breaks down the insulation, which leads to failure. A commonly accepted guideline is that every 10°C increase in operating temperature corresponds to a 50% loss in motor life. Leading standardization organizations conclude that insulation failure contributed to 30% of failures and, of these, 60% were caused by overheating (see “Overheating Electric Motors: One Root Cause of Insulation Failure”, Ernesto J. Wiedenbrug, Baker Instrument Co., www.bakerinst.com/BakerWeb/PDF_Files/Overheating_Electric_Motors.pdf). It’s important to focus on eliminating every potential source of overheating, which includes:

- High ambient temperature

- High altitude

- Dirt buildup on cooling fins

- Mechanical overload

- Poor power conditioning

- Excessive effective service factor

- Frequent stops and starts

- Environmental matters

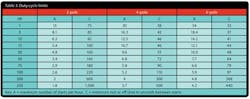

Increasing the motor horsepower in the face of recurrent failures might make the problem worse, according to Wiedenbrug. If the problem is start/stop cycling, be aware that a larger motor has more stringent duty cycle limits than a smaller motor (Table 3).

Heat and other causes such as vibration or mechanical shock might induce electrical problems, including:

- Shorts between conductors or coils

- Insulation-to-ground faults

- Air gap faults, including eccentric rotors

- Rotor faults, including casting voids and broken rotor bars

- Overloading

- Improper matching of motor to load (inertia matching)

- Loose connections

- Vibration/mechanical looseness

The power supply also has the potential to cause motor failure. Some common problems include:

- Overvoltage or undervoltage

- Voltage unbalance

- VFD waveforms

- Voltage surges

Some common tools to identify and eliminate electrical problems are visual inspections, an effective cleaning program, vibration monitoring, motor current analysis, current signature analysis, power-quality monitoring and thermography.

Mechanical modes

Your motors are more likely to suffer from bearing or electrical failure than mechanical failure. But don’t leave the mechanical modes out of your analysis. The primary mechanical motor problems include:

- Bad mechanical fits

- Mechanical unbalance

- Mechanical breakage

- Mechanical resonance

- Rotor deflection

The motor shaft also can exhibit potential problems that should be included in your root cause analysis. These include:

- Bad or worn shaft

- Shaft deformation

- Mechanical vibration

- Wrong coupling type

- Shaft alignment

- Overhung loads

The motor frame isn’t immune from problems, either. Look for:

- Frame warpage

- Broken mounts

- Base plate distortion

- Missing or deteriorated grouting

- Foundation deterioration

- Inadequate foundation size and design

Measures you can take to ensure these problems are uncovered and eliminated include:

- Visual inspections

- Vibration monitoring

- Precision shaft alignment

- Belt alignment and tensioning

- Proper installation

Performing an FMEA or an RCM analysis is time-consuming, but to ensure you get the maximum benefit from the time spent, you must be thorough. This list of possible failures should only be a starting point. As you do your analysis, use this list as a springboard for brainstorming unique modes that might affect your system.

James W. Taylor is director of operations at Machinery Management Solutions, Inc., Clarks Hill, Ind. Contact him at [email protected] and (765) 366-4285.