Canola oil-based hydraulic fluid

Given a choice, many plants would prefer an "environmentally friendly" or "green" hydraulic fluid, especially if it also provides fire resistance. Fire and oil spills are always a potential problem, and plants specify high-priced hydraulic hoses that meet fireproof or fire-resistant regulations, yet continue to pump flammable, toxic, petroleum-based hydraulic fluids through them.

This doesn't make sense when it's possible to use hydraulic fluids that are fire resistant and environmentally friendly, and that perform as well as or surpass conventional petroleum-based hydraulic fluids and out-perform other "food-grade," white mineral oils that claim to be environmentally friendly.

What does biodegradable mean?

Products claiming to have biodegradability are classified as either readily biodegradable or inherently biodegradable. The hydraulic fluid of choice is readily biodegradable. This is defined as degrading by 80 percent within 21 days as measured by a decrease

in a test sample. Most readily biodegradable hydraulic fluids are derived from naturally occurring triglycerides (vegetable oils).

|

View more biodegradable content on PlantServices.com |

The least desirable fluids are inherently biodegradable. These are food-grade lubricants and white mineral oils. Most claim "no sheen," but take longer to degrade in the environment and are toxic to marine life over long periods.

Fire-resistant versus flammable

Hydraulic fluids need to be fire resistant. When in contact with an ignition source, a fire-resistant fluid won't propagate a flame and flames self-extinguish upon removal of the ignition source. Fully compounded vegetable oil-based hydraulic fluids are fire resistant.

Established fire-resistant fluids

During the past four decades, two products have competed in the fire-resistant fluid marketplace: water-based and anhydrous fluids.

Water glycol fluids offer maximum fire resistance at a low price, but they have moderate lubricity only. These four-component fluids contain glycol, polyglycol polymer, additives and from 35 percent to 50 percent water. The problem is the water. Because of its inherently low film strength, the quantity of water required for fire resistance reduces lubricity. Water glycols exhibit a viscosity index greater than 100. This means they tend to exhibit a uniform viscosity across a large temperature range, a behavior that's particularly important at low temperatures.

On the other hand, anhydrous products contain no water. They lubricate much like mineral oil. Synthetic polyol esters (formed by the reaction of a fatty acid with an alcohol, diol or other polyol) are recognized as one of the best-performing biodegradable and fire-resistant hydraulic fluids. Their properties are well documented.

With synthetic polyol esters, lubrication is excellent, as is liquidity and aging stability at low and high temperatures. Polyol esters feature a flash point near 540 F, a viscosity index above 150 and a fire point just above 600 F. As anhydrous fire-resistant fluids, they have proven ideal for applications such as high-performance marine equipment, operating as high as 5,000 psi.

Vegetable oils and additives

Vegetable oils or naturally occurring triglycerides are in the same chemical family as polyol esters. Fully compounded vegetable oil fluids are more than 90 percent biodegradable. Their low total-acid numbers contribute to their good chemical stability and acceptable thermal stability. Their corrosion protection is excellent. While they are good lubricants, their tendency toward rapid oxidation at elevated temperatures has raised concerns about their performance.

A high concentration of linoleic and linolenic fatty acids causes oxidation instability. These acids are characterized by two and three double bonds, respectively. Research shows that the oleic-acid ester distribution in a naturally occurring ester-base stock plays a major role in fluid performance. More double bonds make a material more prone to rapid oxidation. In addition, a high degree of unsaturation leads to increases in viscosity and total acid number, as well as aggressiveness toward copper and copper alloys. However, combining specially formulated additive packages with selected vegetable oil base stocks overcomes these deficiencies.

Additive technology provides fire resistance consistent with Factory Mutual guidelines. Tests have demonstrated that additive technology can enable vegetable oils to perform like polyol esters. This is because the formulations for finished synthetic polyol ester and naturally occurring triglyceride fluids are identical (with the exception of the ester base stock). Both contain viscosity index modifiers, rust and oxidation inhibitors, extreme-pressure additives, copper passivators and defoamers.

Laboratory tests

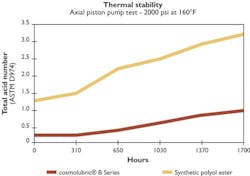

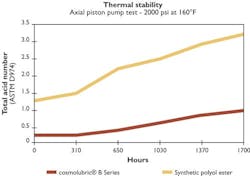

Several laboratory tests have tried to determine whether additives could fortify vegetable oils to improve their oxidation stability to that of synthetic polyol esters. The research began with canola oil base stock with additives for benchmark comparison against a commercial, premium synthetic polyol ester fluid. When testing was completed, the canola oil with optimized additive package was found to provide overall performance comparable to the synthetic fluid, including:

LubricationWhen properly formulated, both fluids passed FZG stage 12; Shell 4-Ball results (1,800 rpm, 40 kg, 1 hr, RT) were 0.30 mm.

Pump TestingThe Vickers 35VQ Vane Pump Test is a severe, mobile-equipment wear test. The standard test procedure requires that the same charge of fluid be tested with satisfactory results in three successive 50-hour test runs. Total ring and vane wear must be below 90 mg in each run. A commercial vegetable oil-based fluid passed the test. Results from ASTM's D2882 pump-wear test also were exceptional. Ring and vane loss was less than 12 mg for both the synthetic polyol ester and properly formulated canola oil. These results are on par with high-performance hydraulic oil.

Oxidation stabilityThe Rotating Bomb Oxidation Test results ranged from 55 to 180 minutes for several synthetic polyol esters and 165 minutes for canola oil with an optimized additive package.

These tests and others prove that in terms of lubricity, oxidation stability, fire resistance and overall greater biodegradability, a fluid based on naturally occurring triglycerides can be formulated to perform as well as a synthetic polyol-ester fluid.

The combination of a growing desire for biodegradability as well as renewable, less-costly alternatives, suggests that canola oil-based products can replace petroleum-based hydraulic oils, white and food grade mineral oils and synthetic polyol esters, especially where fire resistance is a concern.

LeeRoy J. Patin is the global manager of Houghton Offshore and Houghton Marine, a division of Houghton International Inc. Dennis K. James is the company's U.S. Gulf of Mexico marketing manager for fluid products. Both are reached at 713-532-5300, fax 532-5311.

Figures: Houghton Offshore