Understanding the potential of IIoT for industrial motor maintenance

The Industrial Internet of Things (IIoT) may be unfamiliar to some, but its impact on machinery condition monitoring (MCM) is growing. Of course, the underlying technologies for MCM have been around for decades. What’s “new” with IIoT is that the sensors are wireless and communicate digitally to cloud-based data management resources that use artificial intelligence (AI) technologies to analyze vibration, temperature, electric motor current, and similar parameters.

These innovations will potentially provide lower-cost MCM and more accurate fault detection and diagnosis. While they won’t change the way electric machinery is repaired, they could move service centers who use IIoT to the top of the list for repair services when a fault is detected. But MCM and IIoT systems are not free, and the results of this inexact science are not always correct.

Importantly, these new IIoT technologies focus on the MCM market, which is ancillary to the machinery repair market. Predicting and identifying a developing machine fault will not eliminate the need to repair it. Service centers that provide predictive maintenance field services should see IIoT technologies as an opportunity to expand their capabilities and offer more maintenance services to customers.

State-of-the-art IIoT in motor maintenance

Among the first implementations of IIoT technologies was the concept of the “smart” motor, a collaborative effort of electric motor and vibration analysis instrument manufacturers that originated in the 1980s. The idea was to embed condition sensors in the motor so a controller could detect developing machine faults and relay the data to the motor manufacturer or other stakeholder. Having virtually real-time data on machine condition would allow the motor manufacturer to improve machine design and reliability. From a marketing perspective, it would also make them first in line to provide repair/replacement services. Making condition sensors integral to motor-drive controls could also create a “lock-out spec” for replacement motors.

While development is ongoing and information can be difficult to find, the IIoT systems from major motor manufacturers generally consist of battery-powered, single-point sensors, commonly mounted on the stator frame. The sensors can detect overall vibration, temperature, and in some cases, motor current via a stray flux sensor. They can also calculate rotating speed from motor current (rather than measuring it with a sensor) but do not routinely capture or monitor dynamic vibration and motor current signals. These IIoT systems are proprietary and report motor condition to stakeholders by cloud-based AI programs.

Monitoring vibration and motor current can indicate general machine condition. These dynamic parameters also have frequency and phase characteristics that potentially can provide a more detailed indication of machine condition and help diagnose specific machinery faults.

Present IIoT systems provided by electric motor manufacturers are reasonably priced options, not universally included as a standard “smart” motor. The market for these options, however, is limited to the 20-30% of customers who already subscribe to a preventive/predictive/proscriptive maintenance philosophy.

Motor manufacturers are understandably reluctant to make these systems a standard feature, adding cost to their product in what is largely a commodity market. As an optional product, these systems provide value to both the manufacturer and to the end users. With current market penetration of probably less than 1%, implementation of electric motor manufacturer IIoT systems should continue to grow. If a major motor manufacturer ever makes a “smart” motor “standard” without raising the price, the landscape for IIoT systems certainly would change.

Elements of IIoT systems

At this point, it may be helpful to review the elements of an IIoT system. These include machine-mounted wireless transducers, a wireless communication scheme to route data to an internet connection and to the cloud, and a cloud AI data management and assessment resource. Numerous types of machine-mounted transducers are available, with varying arrays of measurement capabilities. Vibration and temperature are standard, with stray motor flux, direct speed measurement, and infrared (heat). Universal transceivers also can be wired locally to other sensors.

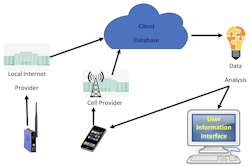

The transducers provide the analog-to-digital conversion and communicate digital data to the Internet (see Figure 1). Bluetooth is the most common transducer communication protocol linking them to an Internet resource, usually via wireless router. Direct communication to cell phone networks is also possible. Data is routed to some cloud-based AI resource that manages and interprets the data and provides feedback to stakeholders subscribed to the system (see Figure 2).

The role played by artificial intelligence

Broadly speaking, AI is any computer-based program that makes decisions on data that a person would otherwise make. AI resources are proprietary to specific system vendors, so data storage, analysis, and reporting vary significantly. An understanding of general AI techniques will be helpful.

AI programs may be “directed” or “undirected.” Undirected programs could be considered “supervised” or “unsupervised.” Common “directed” AI programs might include bookkeeping systems, optimizing algorithms such as GPS systems, and expert systems for vibration analysis. These programs do exactly what they are “directed” to do.

Currently, most AI programs that manage wireless MCM transducer data are “undirected.” Rather than making decisions based on hard-coded evaluations of input values, decisions are made by statistical inference, i.e., they calculate the statistical likelihood that one of several possible solutions is correct. When a directed AI program produces an incorrect result, it can be attributed to an error in the logic of the program and change to that logic would be in order.

With undirected AI, it is understood that within a statistical margin of error some results will be incorrect. This expectation of errors is evident in AI interpretation of image data (pictures). For example, an FBI facial recognition AI program may return several possible matches for a submitted image from millions of file photos. A person would confirm if any of the several possible matches was correct.

Once concern with undirected AI programs applies to their use in evaluating dynamic signal data for vibration and motor current dynamic signals (see sidebar above). These data originate as digitized waveforms (time domain) and can be converted to spectra data (frequency domain) via Fourier transform.

It is one thing for a computer program to evaluate a collection of various values such as temperature, speed, vibration overall amplitude, or motor current overall amplitude. It is quite different for a program to evaluate spectral arrays of values, which have structured meaning without providing that program with the structure.

One proposed solution is to present the dynamic signal data as the digital equivalent of an image and have the AI program evaluate the data using image-analysis techniques. While this may be possible, the initial data collection method and formatting may significantly affect the accuracy of image evaluation. Although overall values from dynamic signals may be adequate for base-level fault detection, fault analysis using spectral data is a much more complex and imprecise science.

Another concern for the effectiveness of undirected AI applied to MCM data is the need for labelled data. Labelled data is required for machine learning. (Machine learning is a characteristic of supervised AI vs. unsupervised AI, which simply finds trends and patterns in abstract data.) When an instance of data is directly linked to an actual event, that data is labelled and an AI algorithm can compare new data to that labelled data to calculate the likelihood of a match.

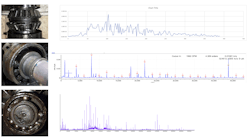

Figure 3 illustrates labelled data, instances of vibration spectral data linked to actual machine failures. For MCM that means someone must actually, physically inspect failed machines to properly label the MCM data. At this point it is unknown how and where those physical inspection occur and by what means the results are provided back to the data scientists to properly label data.

Forces shaping the IIoT market for motor repair and MCM

It is challenging to predict how IIoT may affect the future of motor repair and MCM. However, three key forces are shaping these markets today: the battery life of wireless sensors; communication of sensor data to the cloud; and the development of AI capabilities to manage dynamic signal data (vibration and motor current).

A significant concern limiting the viability of present IIoT systems is battery life. Most sensors have about a three-year battery life expectancy. Procedures for changing batteries, or simply replacing the sensor, present an ongoing maintenance issue. Cutting edge energy harvesting technology holds promise for mitigating the battery life issue, and some manufacturers are exploring direct power sensor options.

While some level of Internet connectivity is available in many machinery environments, connecting large numbers of MCM sensors will overload the connectivity available for many of them. Also, large numbers of connected sensors could open the door for security concerns related to hacking. One looming force that may affect connectivity is the planned implementation of G5 networks. A discussion of G5 is outside the scope of this article, but one objective of G5 is the ability to handle very large numbers of individual remote devices.

Perhaps the biggest question mark about the future of the market is the use of AI to evaluate MCM data. These resources are in their infancy, so it is difficult to envision what more mature resources might be capable of producing. It is reasonable that fault detection will advance to a very useful level. But the more complex task of determining the cause of the fault will depend on programming innovations yet to come.

Nonetheless, some impacts of IIoT technologies seem evident. While the MCM market will continue to evolve, it will be an evolution not a revolution as technology advances, new vendors enter the market, and MCM gains wider acceptance as a profitable endeavor. However, the availability of remotely collected MCM data in the cloud is improving the ability of plant engineers to understand asset health in real time, and in many cases is removing many of the geographic limitations associated with in-person physical inspections and data analysis.

The marketplace for IIoT/AI technologies will grow in the next decade, and both plants and service providers that embrace IIoT technologies and grow with them will have an advantage over those who don’t. At some point, when the technological advances level off and implementation becomes more standardized, consolidation will occur around successful providers with the financial resources to absorb the smaller ones. As with any new technology, now is a time of opportunity for IIoT. Those venturing in should keep their options open and carefully manage risk.

Technical note: Monitoring the overall levels of vibration and motor current can indicate general machine condition. The frequency and phase characteristics of these dynamic parameters can provide a more detailed indication of machine condition and help diagnose specific machinery faults. Interpretation of frequency and phase values requires much more sophisticated data processing than overall values.

About the Author

Eugene Vogel

Eugene Vogel is a pump and vibration specialist at EASA, Inc., St. Louis, MO; 314-993-2220; (fax) 314-993-1269; www.easa.com. EASA is an international trade association of more than 1,700 firms in nearly 70 countries that sell and service electromechanical apparatus.