One of the greatest dangers to your cold storage area may be right under your feet: frost heave. This article addresses what frost heave is, how it occurs, and why electrical heating cables provide the most reliable means to prevent it.

Frost heave takes place when the temperature of saturated sub-grade soil below the concrete floors of a cold storage area dips below 32 °F causing pockets of moisture within the soil to freeze. The culprit here is cold air penetrating the storage area’s concrete floor and past the floor’s protective insulation. Warm air in soil naturally moves toward the cooler, lower pressure air inside the storage room until the two are balanced. Once the sub-grade soil freezes it forms ice lenses that push upward with enormous pressure, “heaving” the concrete above, lifting columns, and distorting the building’s foundation. Frost heaving can also cause cryogenic tanks to collapse and leak LNG, which can be hazardous to the environment. If left unchecked, severe frost heave can result in an entire building being condemned and demolished.

Frost heave moves slow. At first you may only see small cracks and bulges in the concrete. Or you may notice the floor grade becoming uneven, leading to disrupted pallets, tilted racks, and problems maneuvering forklifts. Doors no longer close. The room’s corners also may appear to be sinking. Without repair, this will continue until the structural integrity of the building is severely compromised.

Repairs can be very expensive. The frozen soil must be remediated and re-compacted. New concrete floors have to be re-poured. While being repaired, the room is shutdown to allow the ice to thaw and the floor to settle. This can take several weeks in some cases and obviously disrupts productivity, as racks are emptied of inventory and removed.

To avert soil beneath the slab from freezing, underfloor heating systems are typically installed. The amount of heat required is dependent on the slab surface temperature, how much insulation has been installed, the thermal properties of the soil, and the volume of moisture within it. High quality, moisture-impermeable insulation suitable for below-grade application can be installed to reduce the amount of heat required, although its cost usually prohibits use in large areas. The amount of heat necessary can further be decreased with poly vapor barriers, slip-sheet, and non-frost-susceptible back-fill. In general, one inch of insulation is thermally equivalent to about two feet of soil.

Soil heating methods

Each soil heating method has its advantages and disadvantages. The right system for you will be determined by installation and design, lifecycle costs, and maintenance requirements.

Natural ventilation. This method depends on air flowing freely through ductwork within the concrete below the insulation. The advantage of natural ventilation is that it is easy to install and requires virtually no maintenance. And of course, there are no energy costs. On the downside, it is susceptible to frost, requires regular inspections to ensure the ductwork is clear, and it must be installed above ground level. Designing these systems can be tricky because of the complex thermodynamic calculations involved.

Forced ventilation. This system uses warm air forced through ductwork underneath the cold space by a fan. This warm air is sometimes collected from exhaust air from a process or engine room. On the plus side, forced ventilation provides control over the temperature of the air being circulated. The duct sizes can be smaller than in natural ventilation, as well. However, it can be expensive to install, is subject to damaged or blocked ductwork, and must be regularly inspected. Condensation is commonplace within the ductwork that may turn to ice leading to plugged up pipes and system failure.

Pumped fluid. Here, heated pumped fluid is sent through a piping network under the slab so that its heat is released to prevent soil freezing. Fluids are normally heated to approximately 65 °F with the most commonly used fluid being propylene glycol. Advantages of pumped fluid systems are reliable operation, the cost efficiency of using waste heat from the refrigeration system, and the ability to operate the system year-round no matter what the weather.

Disadvantages of pump fluid systems include the difficulty of locating leaks and repairing them. Piping material deteriorates over time to cause leaks, which presents an environmental issue with glycol as well as costly repairs. Because of its solubility in water and lack of adsorption and partitioning to soils, propylene glycol has high mobility in soil and the potential to leach into groundwater. The rate of biodegradation is slower in lower ambient soil temperatures found underneath cold storage spaces.

Heating cables. Perhaps the best option for preventing frost heave is the installation of self-regulating electrical heating cables within conduit embedded in the substructure. Self-regulated cables automatically adjust their heat output with temperature fluctuations for safer, more efficient operations.

In a self-regulated cable, the electrical power wires are co-extruded into a heating element consisting of a polymer-based material with carbon particles. This provides a resistance path, hence a circuit along the length of the heating cable. Resistance and therefore the precise output of the heating cable vary depending upon the outside temperature, due to microscopic expansion and contraction of the polymer.

Power output is reduced as the temperature increases. Conversely, at lower temperatures, the power is increased. No thermostat is required because the cables automatically vary their heat output based on changes in the surrounding temperature. Self-regulated cables deliver maximum freeze protection and temperature maintenance plus can be cut to any length on-site quickly and easily. Energy-saving digital temperature controllers can be added to give users regulation over single heater segments with remote alarm contacts and GFCI protection.

When compared to air or glycol systems, self-regulated cables provide superior monitoring and control with less maintenance, whether they are protecting cold rooms, freezers, ice arenas or virtually any refrigerated commercial application. Conduit allows cables to be replaced with newer cables should the need arise. Another plus is that there are no environmental issues as there are with glycol.

Design considerations for electrical heating cables

Establishing the correct design, procurement, and installation of self-regulating electrical heating cables ensures a long-term heat tracing solution for your cold storage space. Design considerations would include the size of the facility’s surface area, the thickness of the concrete, substrate and insulation, the room temperature, and whether the installation is above or below grade.

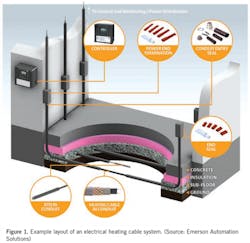

The layout of the conduit, which can be either metallic or non-metallic, is a major design factor. Conduit can be installed in a “looping” pattern so that NEMA 4 junction boxes can be conveniently situated along one wall. Or, if the room is too long, the contractor can run straight conduit under the floor that locates junction boxes on walls opposite each other. Normally, these junction boxes are installed one to two feet above the concrete surface (see Figure 1).

Additionally, be mindful that the layout and number of bends should be arranged so that the pulling force is excessive. Per the National Electrical Code, Article 348-10, “There shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, e.g., conduit bodies and boxes.”

Heating cables should be tested at a minimum of three times:

- while still on the reel

- after connecting power and end terminations

- upon completion of the concrete pour.

Installing electrical heating cables beneath the floor of cold storage spaces maintains above freezing soil temperatures, preventing ice building up in the ground below and the costly damages of frost heave. Compared with traditional means of protection, electrical heating cables are easier to design, install and maintain, environmentally safe, energy-efficient and cost-effective.

This story originally appeared in the January 2022 issue of Plant Services. Subscribe to Plant Services here.

Matthew Gurreri is a product marketing manager at Emerson Automation Solutions, where he leads a team of heating cable product managers.