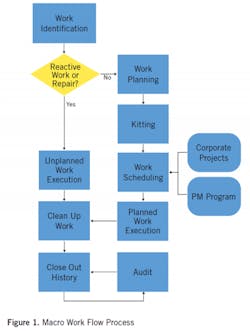

In 2019, the plant engineering department of McKee Foods Corporation in Collegedale, TN started an initiative to improve equipment reliability, which we called McKee Maintenance Excellence (MME). MME included many of the typical elements of a maintenance improvement program such as: Work Execution, Preventive Maintenance Optimization (PMO), Root Cause Analysis (RCA), and Precision and Predictive Maintenance. As we began to put together a plan on how to accomplish this, we quickly realized that we did not have standard processes to build on, and we needed to get our foundation right. This effort began by documenting how work was currently accomplished and comparing that to what world class looked like. Focus teams with people from departments across the company were put together to start building these processes (see Figure 1). Without these processes, there would have been nothing to train our people on nor anything to audit against later. This was by no means the most glamorous part of our initiative, but it was one of the most critical parts of what we did to start our journey.

Have you ever heard of the “Flavor of the Month”? Most improvement initiatives began with great expectations and a lot of energy. Usually they are driven by some KPI that is not trending or tracking the way it should. Sadly, most of those initiatives end when the next flavor shows up. We were bound and determined not to let our reliability journey follow the same path that most other programs had trod. So we asked ourselves, why do most initiatives fail? The answer was simpler than you might think. It is all about the foundation you are building on. Just as you would not start building a house without digging footers and using rebar and concrete to set a foundation, you cannot start your reliability journey without laying down solid processes that can be built upon.

Key findings: Involve your technicians

Many of these initiatives fail because they are top-down driven, which creates a lack of buy-in from the technicians on the floor. You will find that by forming teams of technicians that are closest to the existing processes, it will actually create an energy around the initiative on the floor. The technicians are energized by having the opportunity to change the parts of the existing processes that frustrate them, and that will help to sustain the implementation when you enter the valley of despair. The teams that help create the foundation will work hard to ensure that what they have created succeeds. It is also helpful to have people from other departments involved so when the rollout of the initiative makes it to their area, they can be the champion and subject matter expert on the new processes. Not just anyone has what it takes to be one of these team members though, and below are some of the attributes that a good team member should have, such as:

- Be willing to share information and credit for creating the processes.

- Have a real interest in the initiative and the success of it.

- Be willing to bring their skills, expertise, and experience to the table.

- See the bigger picture of the initiative and be willing to work in the details.

- Have a good understanding of the current processes and issues involved.

- Be willing to be a change agent amongst their peers.

Start with current state

Your teams will need to start by defining the current state. It is very important that you know where you are so that you can form a gap analysis to what your new process needs to be. This does not have to be a fancy document; it can simply be post-its on a piece of paper.

As a word of warning, you might be surprised how work currently gets entered and completed in your plant. You will need a strong team leader that can bring out what hidden processes have been in practice. This is also very important because it can point out the barriers to implementing new processes. The system you currently have is perfectly designed to operate the way it is operating today. In other words, your technicians are doing what they are doing for a reason. The task of defining your current state allows you to have conversations on the front end about why they do what they do, which saves you some headache and time in the end.

You may be asking how we came up with what our new processes would be. We used world-class suggested processes to create our future state processes. We found these by doing research on the SMRP website (www.smrp.org) and benchmarking against other companies in industry that are considered to have world-class reliability programs.

Create an auditable process

Your finished product needs to be robust but as simple as you can make it. The harder the process is to follow, the less likely it is that your people will be able to execute it properly. However, the process does have to be robust enough that you can audit how your department is adhering to it. These are the processes that will serve as the foundation of your reliability program (see Figure 2). If all of these new processes are not followed, you will not achieve the desired result.

For example, if your department is not following the work identification process (the process on how work enters your work order system) then you cannot count on your planning and scheduling processes to work. This would look something like your maintenance technicians identifying work on the floor but not using a work request to get it into the work order system. They might simply write an emergency work order, gather their own parts, and do the job. Now if it is truly an emergency that could be perfectly fine, but we would expect that to bea communicated to supervision. If it was not truly an emergency then the technician will not be able to complete the work that had been assigned to them by the scheduler. You usually can see this in your schedule breaker metric if you have one.

Outcomes

When you set a good foundation built on standard processes your reliability program can take big strides in turning your department from reactive to proactive maintenance. The results in Figure 3 would not have been realized though if everyone was not following the same processes for everything from work identification to planning and scheduling.

From reactive to proactive

Standard processes are the foundation of what a healthy reliability program are built on. They will guide you through the tough times when you are transitioning between being reactive to being proactive. Start with your current state and benchmark against world-class to develop your action plan on moving forward. Once you have that plan form teams to focus on writing the new processes, and remember it is important that these teams are made up of the technicians that are closest to the process.

This story originally appeared in the June 2022 issue of Plant Services. Subscribe to Plant Services here.

Tommy Qualls works for McKee Foods Corporation as a plant maintenance superintendent at its facility in Collegedale, TN. He began his career in 2006 in the corporate engineering department and eventually became a reliability engineer at the plant where he currently works. He has been a CMRP since 2017. He holds a BS in Engineering from Tennessee Technological University and a MBA from the University of Tennessee at Chattanooga. He is currently in charge of deploying the new maintenance excellence program in his part of the plant at McKee Foods Corporation and has been the team sponsor for the development of their precision and predictive programs.

Brandon Lewis works for McKee Foods Corporation as a reliability engineer at its facility in Collegedale, TN. He began his career in 2018 in the corporate engineering department and eventually became a reliability engineer at the plant where he currently works. He holds a BS in Engineering from University of Tennessee at Chattanooga. He is currently the project manager in charge of deploying the new maintenance excellence program McKee Foods Corporation.