Don’t you just love that eureka moment? The exhilaration you feel when you find that missing piece of the puzzle that cascades into many other pieces quickly falling into place? It’s a swell of satisfaction, pride in perseverance, and joy in the outcome.

A eureka moment occurred for us recently when conducting our research on supplier quality management (SQM) – it might lead to a similar moment for you. Among other things, the SQM research leveraged five years of market survey data to characterize the state of SQM maturity, identify the journey to mature SQM, and quantify the correlation between adoption of SQM best practices and KPI improvements. It became clear that while SQM is critical to the quality department (obvious), it is also critical to other functions (not always so obvious).

Better SQM means better manufacturing operations

It is perhaps intuitive that suppliers that provide nonconforming or late shipments can idle production lines and cause late delivery. It can be a one-off issue arising from a typically low-risk supplier, more-frequent issues from higher-risk suppliers, or those occasional “what were we thinking?” scenarios. “Wait, production stopped at $nn,000/hour because we sourced specialty bolts from a supplier that has only two thread forming machines and needs 100% capacity from both to make schedule? How did their PPAP – production part approval process – get accepted? Where were the supplier audits?”

Like it or not, the quality department owns shop-floor disruptions caused by poor SQM. As we’ll see in a moment, companies mitigate – but don’t eliminate – these issues with cross-functional, risk-based SQM teams and processes supported by appropriate technology. However, the converse also is true, and LNS suggests viewing this in a positive light. Manufacturing operations improve through better SQM. It is in a manufacturing operation’s interest to have a mature, efficient, and capable quality and SQM operational excellence model (incorporating people, process, and technology).

Better by how much?

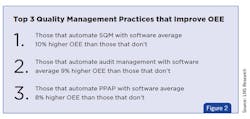

How much of an impact does SQM have on manufacturing operations? To answer that, let’s dig into some numbers. As part of its quality management practice, LNS Research tracks the adoption of 46 best practices and 8 KPIs, including overall equipment effectiveness (OEE) and on-time delivery – two critical manufacturing operations KPIs. LNS analyzed all 46 best practices against these two KPIs by comparing the average KPI of those that adopted a best practice with those that did not. We then expressed the KPIs in terms of percentage improvement. For instance, companies that include suppliers in design-for-quality initiatives experienced an average of 4% higher on-time delivery than those that did not. LNS then ranked best practices from highest to lowest to identify the highest-impact practices by KPI. If companies that adopted SQM best practices saw improvements in KPIs, they’d bubble to the top of these ranked lists.

How did SQM practices do as compared with all tracked quality best practices? First, let’s consider the impact of SQM on on-time delivery. Six of the top 10, and 10 of the top 15 quality management practices that improve on-time delivery are associated with cross-functional, risk-based SQM teams and processes supported by appropriate technology (see Figure 1). Clearly, SQM has played an important role in improving on-time delivery, and companies on average experienced a 4%–8% improvement in on-time delivery depending upon the SQM practice adopted.

Overall equipment efficiency (OEE) exhibits similar results. In fact, the top three quality management practices that improve OEE are associated with adoption of cross-functional SQM processes and appropriate technology (see Figure 2). It’s clear that companies that adopt SQM best practices improve OEE and on-time delivery – substantially so in some cases.

Critical element: Culture of collaboration

SQM helps improve OEE and on-time delivery, but manufacturing operations also plays a pivotal role in its success. While the quality department should lead quality activities, effective quality management and SQM is truly a cross-functional responsibility. Unfortunately, LNS statistics show that 77% of companies do not have a cross-functional culture of quality.

The reality is that a cross-functional culture of quality does not need to be difficult or to add appreciable work. In fact, it is likely to reduce total work because additional work performed during strategic and planning phases tends to reduce firefighting. As an example, one LNS council member recently adopted advanced product quality planning (APQP), an automotive development process that includes quality and design for manufacturability activities during product development to improve product and process quality. This process was different but no harder than the previous processes to implement. However, new equipment developed with APQP has 75% lower warranty costs.

Dan Jacob is a research analyst with LNS Research; he focuses primarily on enterprise quality management systems with collaborative coverage across automotive, aerospace & defense, high-tech and electronics and medical devices. LNS Research provides advisory and benchmarking services to help line-of-business and IT executives make critical decisions. Learn more at www.lnsresearch.com/blog.

To improve OEE and on-time delivery through improved SQM, manufacturing operations should partner with the quality department. This can take several forms. Consider the following actions:

- Work together with the quality department to build cross-functional teams and processes that connect quality between design, manufacturing, and suppliers.

- Work with the quality department to define a common risk framework and technology that will aid in identifying, quantifying, prioritizing, and mitigating risks across operations.

- Communicate to senior management the impact of SQM on manufacturing operations. Quality often has a fragmented technology landscape, which can prevent meaningful engagement by other functions. Resources will be needed to consolidate and automate this landscape.

Benefits abound for “us,” “them,” and everyone

Was there a eureka moment in there for you? Maybe the perspective that SQM is nearly as important to manufacturing as it is to quality, or that cross-functional processes, teams, and technology centered on SQM can create competitive differentiation, was an eye-opener. Regardless, the next time there’s a discussion about improving on-time delivery or OEE performance, consider SQM as one potential solution.