How can we be more efficient? One often overlooked area is the rotating systems used in manufacturing and power generation. By examining torque on these systems, downtime can be reduced, product quality improved and energy efficiency maximized.

What is torque?

It's a measure of the forces that cause an object to rotate. Reaction torque is the force acting on the object that's not free to rotate. An example is a screwdriver applying torque to a rusted screw.

With rotational torque, the object is free to rotate. Examples include industrial motor drives and gear reducers.

Torque and RPM determine horsepower, and horsepower determines system efficiencies.

hp = T * v / 63,025

j = hpo / hpi

where T = torque (in.-lbs.)

v = revolutions per minute

j = efficiency

hpo = output horsepower

hpi = input horsepower

Torque measurements are used for process control. For example, a lumber mill uses a predetermined maximum torque to initiate blade changes. This saves wear and tear on the drive system and increases product quality.

Many similar applications exist in manufacturing. Monitoring torque is sometimes critical to the performance of axles, drive trains, gear drives, and electric and hydraulic motors. Other in-plant applications include gas and steam turbines.

Getting the measurements

The need for torque measurements has led to several methods of acquiring reliable data from objects moving. A torque sensor, or transducer, converts torque into an electrical signal. The most common transducer is a strain gage that converts torque into a change in electrical resistance. The strain gage is bonded to a beam or structural member that deforms when a torque or force is applied. Deflection induces a stress that changes its resistance. A Wheatstone bridge converts the resistance change into a calibrated output signal.

The design of a reaction torque cell seeks to eliminate side loading (bending) and axial loading, and is sensitive only to torque loading. The sensor's output is a function of force and distance, and is usually expressed in inch-pounds, foot-pounds or Newton-meters.

Reaction torque sensors are used when limited rotation won't damage the cable. Its use minimizes the error attributable to the inertia of rotating components. They are used to calibrate torque wrenches, test the breaking torque of aircraft fasteners and monitor the opening torque of child-proof containers.

Other widely accepted methods for measuring torque rely on mounting transducers in the machine train or on the rotating shaft. With few exceptions, these methods use strain gages. Each method has advantages and limitations, many of which are application dependent. The best solution requires an in-depth understanding of the application.

Two common ways to obtain torque measurements are by strain gaging the shaft and by using in-line torque cells. Both have two technical obstacles: getting power to the gages over the stationary/rotating gap and getting the signal back. The methods to bridge the gap are either contact or non-contact.

Gaging the shaft

With strain gages bonded to the shaft, the shaft becomes the transducer.

The general guideline is that the applied torque must induce at least 150 to 175 micro-strain. The second requirement is for the shaft to be calibrated, a process that usually involves loading the shaft statically and tabulating the results. This is relatively easy to do in small systems, but as loads and shaft size increase, it becomes an onerous task. Selecting a location for the strain gages, mounting them carefully and protecting them become problematic for users inexperienced in such techniques. Outside contractors are usually available through the torque sensor suppliers for most applications and locations.

Constant movement

Slip rings are used in contact-type torque sensors to apply power to and retrieve the signal from strain gages mounted on the rotating shaft. Slip rings are susceptible to wear. Maintaining an oil-free slip ring is not always easy in many industrial applications. Slip ring brushes, as well as the support bearings internal to these torque sensors, eventually wear out.

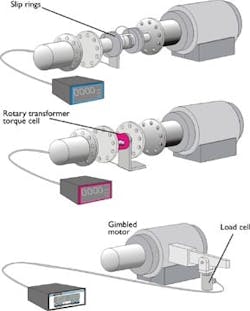

Figure 1 shows three common hardwired measurement schemes.

Figure 1. Moment arm, rotary transformer and slip ring methods for measuring shaft torque.

Non-contact methods

Radio telemetry of the signal coupled with wireless induced power for the strain gage excitation offers an easy solution for bridging the stationary-rotating gap. A stationary antenna induces power in a loop antenna on the rotating shaft. The power from the rotating shaft antenna is conditioned and excites the strain gages. A shaft-mounted radio transmitter sends the measurement signal back to the stationary antenna. The telemetry antennas need to be somewhat flexible for ease of mechanical installation, and receivers should have adjustments for peak coupling of the antenna for maximum induced power and received signal strength.

The radio antenna gap is normally less than 3/4 in. Radio telemetry systems are reliable and easy to install, but cost more. Their main advantage is the lack of contact and need for maintenance. There are no support bearings or mechanical contacting parts to wear out.

In-line rotary torque transformers are best for measuring torque when transducers are mounted in-line with the rotating shaft. These consist of a strain gage torque cell having a calibrated output and inductively coupled to the stationary windings on the assembly by a rotary transformer. The rotary transformer couples the strain gages for power and signal return. The rotary transformer works on the same principle as any conventional transformer except either the primary or secondary coils rotate. The rotary transformer is simple and easy to use, and is usually applied to smaller machine trains. Rotary transformers have some susceptibility to noise and require bearings for support, which also implies maintenance. The act of mounting the in-line transducer changes system dynamics and can mean the torque values themselves may change.

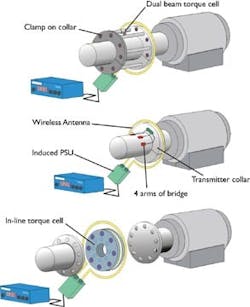

Figure 2 shows typical wireless measurement schemes.

Figure 2. Wireless torque monitoring systems, including clamp-on collar, strain-gaged shaft and inline torque cell.

In-line wireless torque cells

Wireless torque cells consist of a rotary torque transformer connected in-line with standard industry flanges, coupled to the stationary portion of the assembly by wireless transmission. It includes a stationary loop antenna that induces power into an embedded antenna on the rotating torque cell, which supplies the excitation voltage to the strain gages and power to the radio transmitter mounted in the torque sensor. The radio transmitter modulates the strain signal for transmission to a stationary antenna. In-line torque cells offer high torsional stiffness to maintain system dynamics. They are pre-calibrated, and most have an internal calibration system that supplies a calibrated output signal to adjust instrument span in the absence of a known static torque. The wireless telemetry feature eliminates support bearings and their maintenance. In-line torque systems require cutting the shaft or lengthening the machine train to accommodate the inserted in-line transducer.

Clamp-on torque cells

A clamp-on torque cell works on the wireless telemetry principle with the inherent advantages of a non-contact system. It's immune to oil and dirt, but has the advantage of not requiring the rotating shaft to be cut. The clamp-on torque cell is a pre-calibrated bending beam mounted between two collars that clamp on the shaft (see Figure 3). Accurately spaced knife-edges provide an accurate, reliable shaft torque measurement without marring or modifying the shaft. The clamp-on feature allows the torque measuring system to be moved to other similar installations easily in less than 30 minutes. This means the unit is ideal when torque or horsepower monitoring forms part of the final check-out of multiple machines. It handles shaft diameters from 3 to 32 in. and as much as 100,000 hp.

Figure 3. Clamp-on torque cell

Measuring torque on static or rotating machinery is important for maintaining quality and for continuous operation without downtime. The direct torque sensor measurement is preferred over the remote or indirect methods of calculating torque. Selecting a torque sensor for your application depends upon the required long-term reliability, physical constraints, portability and budget.

Martin Armson, Andy Bell and Jack Feil are with Sensotec, Inc. They can be reached at (614) 850-5000.