In brief:

- A maintenance plan can be calibrated to your company’s typical maintenance technician.

- When writing a maintenance plan, you should be looking at experience, reading level, criticality of equipment, criticality of maintenance task, complexity of procedure, complexity of equipment, interaction with other crafts, and proprietary information from OEM.

Calibrate [kal-uh-breyt]: To plan or devise something carefully so as to have a precise use, application, appeal.

A maintenance plan can be calibrated to your company’s typical maintenance technician. Who is writing your maintenance plans? Engineers? Maintenance planner/schedulers? Maintenance supervisors? Maintenance technicians?

Whoever is writing your maintenance plans should consider that each written plan represents a significant investment of your company’s dollars. It will take an average of two to four hours to write the typical maintenance plan. If your planners make $35/hr with benefits, that will equate to $40-$50/hr, which means your company has invested between $80 and $200 in that maintenance plan. At JEA’s Northside Generating Station (NGS), we have more than 7,000 maintenance plans in our Maximo job plan library. That means we have invested more than $1 million writing, developing and maintaining our job plan library.

What should you consider when writing a maintenance plan? At a minimum, you should be looking at experience, reading level, criticality of equipment, criticality of maintenance task, complexity of procedure, complexity of equipment, interaction with other crafts, and proprietary information from OEM.

Experience

Figure 1. The retiring workforce will be replaced by younger workers, but don’t assume they’re all rookies. Young Tyler has had a set of tools for more than two years and knows all about operating lathes, drill presses, impact wrenches, and hammers.

One key fact needs to be considered when writing your maintenance plans today. Those plans will be used for the next four to five years. What is happening right now with the maintenance workforce? According to the Pew Research Center, more than 3 million Baby Boomers will be reaching age 65 every year for the next 19 years. Many of those will be retiring from the workforce. That means that the audience for your maintenance plans written today may not be the same faces that you know today (Figure 1)

Reading level

A 2010 report by The Education Trust found that 23% of recent high school graduates don't get the minimum score needed on the enlistment test to join any branch of the military. Questions are often basic, such as: "If 2 plus x equals 4, what is the value of x?"

The military exam results are also worrisome because the test is given to a limited pool of people. Pentagon data shows that 75% of individuals from 17 to 24 don't even qualify to take the test because they are physically unfit, have a criminal record, or didn't graduate high school.

What this means to the maintenance plan and procedure writers is they often may need to avoid some of the technical terms or explain their meaning in the body of the document. Also, do not assume that the reader possesses basic math skills, particularly if you are asking him or her to calculate angles or do complicated unit conversions. Tailoring the plan or procedure to the eighth- or ninth-grade reading level will ensure that the reader will be able to comprehend the content.

Criticality of equipment

Any number of conditions or plant configurations can make a piece of equipment critical to the business and therefore in need of more careful and more detailed treatment in a maintenance plan or procedure.

Any vessel designed to contain high pressure, high temperature, or hazardous fluid or gas should be treated as a critical piece of equipment. Send the procedure to the engineering department for review against codes that address the particular fluid, gas, or hazardous material. The codes to consider include but are not limited to American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code 2010 Edition; Occupational Safety and Health Act (OSHA) Technical Manual Section IV: Chapter 3; American National Standards Institute/National Board of Boiler and Pressure Vessel Inspectors ANSI/NBBPVI NB23-2011 National Board Inspection Code — NBIC, 2011 Edition (Three Volumes); and National Fire Protection Association (NFPA) — more than 300 sets of codes and standards that deal with fire protection and prevention.

Every manufacturing and production facility in the United States is subject to being permitted by and regulated by the Environmental Protection Agency (EPA), which has developed and issued a number of policy and guidance documents to help with the implementation of the National Pollutant Discharge Elimination System (NPDES), the Clean Water Act, Section 404, and the Safe Drinking Water Act. If your facility utilizes groundwater or surface water in the production process or discharges any liquid onto the ground or into a stream, lake, ocean, or river, it is likely to be subject to one or more of the above regulatory constituents.

If a piece of equipment is required to reach and maintain the level and quality of production for which the facility was designed, it should be deemed critical equipment. Often, the plant design will include backup or redundant equipment; however, the backup equipment may be out of service, in which case the primary will become critical.

Criticality of maintenance task

Just like there is a huge difference between getting your blood pressure tested and open heart surgery, there are maintenance tasks that can have varying degrees of criticality. These can range from routine preventive maintenance (PM) to major overhauls.

Maintenance plans for routine PM tasks seldom need detailed step-by-step procedures. There may be some detail required to point the technician to the correct oil level, oil fill, or lubrication point. It can be helpful to give nut/bolt sizes so that the correct wrench can be carried to the job site if, for example, a drain plug needs to be removed. Most technicians carry an adjustable wrench or a variety of the most common for the equipment being PMed. Definitely include the exact type, viscosity, grade, detergent, and grease thickener that is required and compatible with the piece of equipment.

Most routine corrective maintenance (CM) procedures deal with minor leaks, looseness in a fastener, malfunctioning limit switch, or some other similar minor annoyance to the operators. These tasks can be treated similarly to routine PMs with the inclusion of some extra information such as gasket or seal material and size.

Invasive PMs are a two-edged sword. There is often good reason to take a piece of equipment apart, especially when you have reason to believe there may be a hidden failure mode undetectable through normal, non-invasive methods. The maxim, “if it ain’t broke, don’t fix it” is not to be disregarded, however. You must weigh the risk against the reward in order to optimize your PM program.

If a piece of equipment has failed to deliver its required output and the mission is in jeopardy, we must perform an invasive CM. Most common are impeller replacements, valve seat restorations, compressor rebuilds, bearing failures, worn mechanical drives, and hot loop expansion joints. For these jobs, the technician needs access to the manuals, parts lists, tool lists, and disassembly and reassembly procedures. Often, the exact cause of failure or diminished performance cannot be determined until the machine has been taken apart, so some after-the-fact planning will need to take place.

The final and most critical category of maintenance task is the overhaul of a large machine such as a boiler, turbine, large compressor chain, or multi-stage pump. These jobs are different from the invasive CM in that the overhaul is usually planned well in advance and can use aids such as critical path method (CPM) scheduling and parts staging, and the overhaul will often be accomplished under the watchful eye of an original equipment manufacturer (OEM) representative.

Complexity of procedure

Figure 2. A 600 MW turbine generator set literally came apart in South Africa because the mechanical overspeed bolt failed to deploy during an overspeed test. Calibration of this mechanical bolt is a complex procedure, and it can’t be tested without going to an overspeed condition.

Several things can add to the complexity of a maintenance plan or procedure. High-speed machinery is much less forgiving of misalignment than the typical 1,200 or 900 rpm pump, blower, or fan. A 600 MW turbine generator set literally came apart on February 9, 2011, in Johannesburg, South Africa, because the mechanical overspeed bolt failed to deploy during an overspeed test. (Figure 2). Calibration of this mechanical bolt is a complex procedure, and the problem is that you cannot actually test it without going to an overspeed condition. That is why at JEA’s Northside Generating Station we pursued and obtained approval from our insurance carrier to conduct electronic overspeed tests in lieu of the mechanical overspeed testing. Both cases call for a high degree of precision in the execution of the work, so this needs to be emphasized in the plan or procedure.

When disassembling and especially when reassembling a complex piece of equipment, the order in which the pieces should be inserted and fastened into the machine isn’t always intuitively obvious to the technician. A detailed step-by-step procedure is helpful in this case and can avoid the frustration of having to take the machine back apart in order to insert one forgotten part.

After a short five-day vacation this past summer, I returned home to discover my pool pump impeller had separated from the motor shaft. After fussing with the motor shaft for a half hour, I took the motor down to my local pool supply store where the young gentleman whipped out a skinny flat wrench that inserted into a slot on the back of the motor to hold the motor shaft in place while he worked on removing the piece of impeller that had fused itself to the motor shaft. It was a simple tool, but it saved a lot of frustration and time getting the old piece off and the new impeller screwed back onto the motor shaft. Often, experienced mechanics will have an inventory of special tools that they’ve modified or made over the years to facilitate their work. Make sure your planner spends as much time as possible out in the field looking over the planned jobs. There’s no telling how many valuable nuggets can be picked up on by just watching.

Complexity of equipment

A typical power plant has several large rotating trains containing three components coupled together. At JEA’s Northside Generating Station, we have three turbine wheels coupled to a generator on our largest turbine and two wheels coupled to a generator on our two smaller steam units. Our plant just across the fence line, partly owned by FPL and JEA, has four turbine wheels coupled to a generator. Alignment of these machine trains becomes an exercise in three-dimensional geometry. Exact sequencing and thermal offsets are all information that is vital to successful alignments of these complex machine trains. There are also specially made shims that must be used for the tight spaces involved.

Many multi-stage pumps are of a stacked configuration. These pumps are required to be disassembled and reassembled in a sequence, alternating between volute and impeller. Each stage can also have a unique clearance tolerance. All of this information must be carefully documented and written into the plan.

Your planners should be familiar with the term “wind up” or what happens to a shaft position if there is back pressure on a gear set such that the gear does not relax into the middle of the back lash of the mating gear. Complex gear sets can present special problems when trying to align them coupled up. It is often best to uncouple the gear box from the driver and driven piece when attempting to align.

Anything that contains high pressure steam or fluid by nature will be more complex and present more of a challenge to the planner when he is crafting his maintenance plan or procedure. He must reference codes already mentioned. He must also research the proper welding procedure for the material, since as pressures and temperatures increase so do the alloy of the steel, which requires complicated pre- and post- heat treatment solutions in order to obtain a proper weld.

Large control valves are often part of an actuator/control/feedback system that can contain several linkages, pistons, hydraulic pressure parts and electronics. Maintenance and then stroking and calibration of these valves often turns into a multi-craft exercise that must be choreographed with control-system, electrical and mechanical technicians.

Not much is more frustrating than getting your piece of equipment apart only to find out the worn-out seal, ring, seat, plug, impeller, or widget has been crafted from some “unobtainium” material by specialized machinists who only work on the second Tuesday of the third month when the moon is full. You get the idea. It is not practical to keep every part for every piece of equipment in your storeroom, unless you are fortunate enough to have a storeroom is as large as the University of Michigan football stadium, which seats 109,901. Actually, it’s only the third largest athletic stadium, behind Rungrado May Day stadium in Pyongyang, North Korea, which seats 150,000, and Salt Lake Stadium in Kolkata, India, which accommodates 120,000.

Like most of us, if you don’t have unlimited storeroom space you are forced to pick and choose which parts you will store. Inevitably, you will find yourself faced with calling trucking companies, overnight delivery services, or even private airplane pilots to fly in a critical part that is holding up production. If your plans anticipate this and have recorded this from a diligent capture of the plan usage history, then at least the calls can be made and shipments started on their way during the early planning stages and not at the last minute.

Interactions with other crafts or operations

Most equipment in an industrial facility has some kind of power or instrumentation that must be disconnected and reconnected in order to complete a maintenance task. In these cases, detailed sequencing aids the maintenance supervisors in planning the week or day in order to have the disconnect/reconnect technician available to do his part of the job and get out of the way so as not to delay the usually longer mechanical part. Accurate durations for these interacting craftspeople is essential.

The controls-system technicians are also going to have to stroke valves, test pump controls, and calibrate hydraulics once the mechanical work is done. The ranges for calibration and history on the previous calibrations are helpful to these technicians.

Along with the calibration and disconnect/reconnect morass, there is the necessity to power up portions of a system so that equipment can be test-run. Careful attention must be paid to the outcome of having power applied to a rotating or linearly operating piece of equipment that has just been reassembled after a complex maintenance procedure. Checklists in the maintenance plan can aid the technician in ensuring that the equipment is safe to operate. Always exercise extreme caution on the first energizing of a rotating or linearly operating piece of equipment.

Proprietary information from OEM

In the interest of protecting intellectual and design property, OEMs often will provide generalized drawings and schematics but purposely omit any feature of the design that could be copied by a competitor. This in some cases makes it difficult for the technician to repair the item. The planners need to maintain amicable relationships with the OEM representatives; in some cases a rep may let you look at the pertinent part of the drawing or proprietary document so that you can extract the needed data without having to take a copy.

| Stephen Cooper is senior manager, engineering & outage services, JEA, Northside Generating Station, in Jacksonville, Florida. Contact him at [email protected] and (904) 665-8805. |

OEMs also will sell the user special tooling it has made in order to make maintenance of the equipment easier. A good example is a turbine balance weight insertion tool. This tool contains a female screw with an outer clamp that allows insertion of the balance weight into the appropriate threaded hole while still maintaining positive grip on the weight. Attempting to insert the weight without this special tool could result in losing the weight inside the turbine, which can be disastrous for the customer. This tool, like other special parts, has to be purchased from the OEM. In some cases, materials and the exact design or configuration of the tool or part are essential to proper operation, and you are better off biting the bullet and paying for an original. In other cases, it may be possible to reverse-engineer any part if the OEM cannot deliver in a timely manner. Be careful of proprietary design rights. The OEMs are protected by law, should you unwisely decide to profit from your reverse-engineered part.

In the case of control systems, often OEMs will protect access to the system with a password. Then the system becomes a black box and you have to call the OEM to send out a vendor so that changes can be made to the program. Be sure to include contact information in the plan or procedure and, again, maintain healthy relationships with the OEM.

Work order plan guidelines at JEA NGS

39 checkpoints in 5 areas of the work order plan

Work order form

- Make sure the “Clearance Required” and “Is This A Modification” fields are properly filled in with a Y or N.

- Make sure the “Location” (GEMS) number is correct.

- The Job Plan name should be the equipment GEMS code followed by an alpha-numeric. You may use a partial GEMS code such as N02-EF-MEGMOTORS when the same equipment is used in multiple locations or if a GEMS code doesn’t exist. The Job Plan description should be similar to the GEMS code description.

- Do not use the PWO problem description for the Job Plan description.

- Do not provide a name for a work plan that is intended to be used only one time.

- Make sure the “Area” field is properly filled in when the “Outage Code” is not zero.

- Make sure the “Work Type” code is correct.

- Make sure the “Outage Code” is correct

- Make sure the “Instruction Book” field is filled in with the proper attachment type — “NO ATTACHMENTS,” “LINKED DOCUMENT,” “PAPER AND LINK ATTACHED,” or “PAPER ATTACHMENT.”

- Make sure the “Lead Craft” field is properly filled in. If a welder or machinist is required, be sure to list them.

- Make sure the “Crew” code is correct. List all crews required.

- Failure remarks (action taken) should be initialed and dated.

- Verify GL account is correct. (PWO is not capital if less than $750).

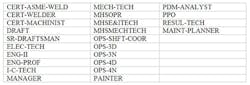

Labor module

Enter the number of technicians and estimated work-hours for the different labor/craft types needed to complete the work. Be careful to list only the labor/craft types being used on the job. Only the following labor/craft types shall be used on the work plan.

- List Oracle inventory item ID numbers for required parts and for parts that may be needed.

- Leave plan quantity zero when quantity is unknown.

- Purchasers enter the staged location of parts in the “Failure Remarks” field. Don’t forget to initial and date the information.

Job operations

- Define scope of problem, if not fully described in the problem description.

- State system parameters such as pressure, temperature, flow, and voltage.

- State safety requirements when more than standard PPE (hardhat, safety glasses and ear plugs) is needed. Do not state, “Wear proper PPE.”

- Do not state, “Obtain clearance from operations.” This just makes the work plan lengthy. This information is provided by the “Clearance Required” field.

- State what is to be done.

- When stating instructions, give a brief explanation of how to do it, if not common knowledge, which could result in equipment damage or personal injury.

- Do not leave blank job operation lines on job plan. The blank lines may cause an extra page to print.

- Give instructions to see attachments, if any, and be sure to name the attachments provided. The intent is to state what the attachment is; state whether it is a CPM, piping sketch, manufacturer’s data sheet, email from PDM, or something else. Don’t forget to attach an equipment manual to the PWO, if needed.

- State torque requirements for any job requiring tightening of fasteners.

- State fastener type, grade, and head size in order for the technician to determine type and size of tool to use, when appropriate.

- If welding is required, make sure the welding procedure is attached and the WPS number is stated in the work plan.

- Give instructions for parts that were removed that should be rebuilt such as mechanical seals, valves, pumps, or motors. They may throw the part away if we don’t tell them it is rebuildable or that we can send it to the manufacturer for credit. Give instructions for the technician to generate a PWO to send the item out for rebuild and return it to stock. If the item is not currently stocked, the technician should fill out an inventory request form (IRF).

- If an MWI was issued, be sure to paste it in the PWO long description. The MWI should be edited to take up less space on the PWO.

- List tools not normally kept in toolboxes and state sizes needed.

- State the quantity of tool items needed. List these quantities with the tool description, since the quantity column is not in service.

- We don’t need to state a toolbox is needed.

- State size for ladders, nylon straps, chain falls, and other equipment.

- List tool room items that might be overlooked. It may save a trip to the tool room.

- Provide names and phone numbers of resources that may need to be contacted to assist with the work.

- List recommended vendor contacts with phone numbers, if known.

- If scaffold erection or insulation removal is required, note it in parenthesis in the beginning of the work order description, e.g., “N01, (SCAFFOLDING REQUIRED) CRH EXTRACTION NON-RETURN VALVE IS LEAKING” or “N01, (INSULATION REMOVAL) CRH EXTRACTION NON-RETURN VALVE IS LEAKING.”

- Repair history: Provide description of previous problems and how they were repaired. Provide dates of the last five repairs. Check history for a maximum of two years. List date, PWO number, and brief description of problem/repair. If history doesn’t exist, state, “No history available.”