Though the adage, “A chain is only as strong as its weakest link,” originated years ago, it applies in today’s manufacturing environment more than ever before. The simplest products manufactured in the United States might contain a variety of outsourced components that absolutely affect the finished product’s quality, availability and performance.

|

View related content on PlantServices.com |

Unlike the chain analogy, outsourcing today means something much different than it did a century ago. In previous times, outsourcing meant manufacturers purchased components made across town, down the road or maybe even in another state. Quality usually remained high because of common practices, a clear understanding of processes and levels of quality, and use of consistent raw materials.

Today, outsourcing can result in components from countries with different languages, cultures and standards of quality coming together at some location to complete one finished product. In an attempt to raise our economies of scale, have we actually complicated the process while simultaneously reducing quality and customer satisfaction. In a 100-link chain, have we compromised strength by controlling the quality of 99 links while outsourcing the one master link that determines overall structural integrity.

Little did steel tycoon Andrew Carnegie, the father of vertical integration, know that some 200 years later his business model would again become the blueprint for success for American companies that choose to control every aspect of their production process rather than relying on outsourcing. Controlling every link in the production chain ensures the highest level of quality. Yes, you pay a premium for those products, but in return, you can rely on consistently high quality. Customers will pay more when they know they are getting more in return. Vertical integration, or in-sourcing, can be a key to ensuring the highest quality and greatest customer satisfaction.

In 2007, Baldor Electric Company acquired 100-year-old Reliance Electric, which manufactured Reliance industrial electric motors, and Dodge, a manufacturer of mechanical power transmission products, from Rockwell Automation. Baldor immediately began assessing the strengths and weaknesses of the three entities, with the ultimate goal of bringing the best practices from each together to develop the highest quality provider of industrial electric motors and mechanical power transmission products.

After purchasing Dodge from Rockwell Automation, Baldor determined it would bring production of its Type-E bearing’s cone assembly in-house.

Since its founding in 1920, Baldor has been committed to controlling as much of each manufacturing process as possible. By so doing, we design, engineer, build and test products that set the standard for high quality and value.

Soon after acquiring Dodge, Baldor began taking an inventory of the products Dodge made to determine how each could be applied to Baldor’s concept of in-sourcing. We learned that one of the most common Dodge products contained outsourced components that we believed could be manufactured internally, with better process control and improved quality.

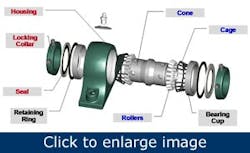

Dodge Type-E tapered roller bearings, a staple product since 1943, contained outsourced, foreign-made cones, one of eight critical components that made up the assembled bearing. Though for more than 60 years, Type-Es have been preferred by users and commanded the largest market share, we decided that this would be one of the first products that Baldor would use to introduce its vertical integration practice into product reality.

When Baldor determined it would manufacture the cone assembly, two major design criteria were defined:

- The manufactured product must meet load and speed limits as currently specified.

- Critical features such as quality, interchangeability with related components, cost and availability must be equal to or better than the outsourced product.

These two requirements were accomplished by bringing together 25 years of experience in ball-bearing design and manufacturing, in-depth roller-bearing analysis, dynamic testing and installation of state-of-the-art manufacturing cells at Baldor’s Dodge bearing facilities in Rogersville, Tennessee and Marion, North Carolina.

The product is controlled in-house from its arrival as raw material to its assembly into one of the many versions of housings. The Rogersville plant purchased new turning, measuring and heat-treatment equipment to accomplish the first stages of production. The Marion plant purchased new measuring equipment, as well as the latest CNC grinders, so the final stages of grinding, assembly and testing can be performed on-site. Baldor also developed a dedicated quality lab to ensure the strictest control possible on quality aspects of the product. Baldor invested more than $12 million to make certain that it achieved absolute quality.

To be certain the new bearings exceeded the outsourced product, Baldor tested all 11 of the Type-E series side-by-side with the former product. In-depth analysis performed on each bearing determined if the material, design and manufacturing process were producing an exceptional product. To date, numerous test bearings in the lab have been in non-stop operation for more than a year, logging more than 420,000 hours of dynamic testing and counting. The results of five critical test evaluations concluded, without exception, that these bearings were significantly better:

- Life expectancy: Exceeds L-10 life requirements

- Cleanliness: 50% less foreign materials than competitive bearings

- Noise and vibration: Equivalent to or quieter than competitive bearings

- Roundness: 60% improvement over competitive bearings

- Concentricity race-to-race: 80% improvement over competitive bearings

Even though the newly-produced bearings passed all tests with flying colors and exceeded Baldor’s expectations, the final and most important test was yet to be determined. That would be customer acceptance.

Since the improvements were made, Baldor has sold more than 45,000 units without a single rejection or complaint. But it’s more than enhanced quality that keeps customers happy with the product. Because Baldor now controls the complete process, customer service has improved dramatically with the ability to respond rapidly to requests for modifications, improved product availability and manufacturing cycle times reduced from 12 weeks to two weeks by not being held captive to the previous supplier’s lead-time schedule. All of this has happened because Baldor chose to in-source rather than continue to outsource the component/process.

In addition, counterfeiting of bearings and other metallic components continues to be a major problem for companies purchasing components from third-world countries. The American Bearing Manufacturers Association is doing its best to fight this issue in Asia. Baldor has eliminated the possibility of counterfeit components presenting potential quality problems in its bearings. This is a bold step by Baldor, one that provides the assurance of the highest quality available.

What Baldor has done has kept jobs in the United States. The outsourced product that was being purchased from another company was made in India. In-sourcing this component not only provides Baldor with better quality, cost and lead time control, it also brings jobs back to America.

Baldor Chairman and CEO John McFarland has a favorite saying that applies to this situation as well as many others at Baldor: “Just because you’re swimming upstream, doesn’t mean you’re going in the wrong direction.” It’s a corporate attitude that isn’t the easiest path to follow, but all can feel that it’s worthwhile when they see each bearing stamped, “Made in the U.S.A.”

Randy Breaux, vice president, marketing, at Baldor Electric Company may be reached at [email protected].