Tungsten is a rare metallic element used for manufacturing TIG (or GTAW) electrodes. The TIG process relies on tungsten’s hardness and high temperature resistance to carry the welding current to the arc, as it has the highest melting point of any metal (3,410°C).

These non-consumable electrodes come in a variety of sizes and lengths and are composed of either pure tungsten or a hybrid of tungsten and other rare earth elements and oxides. Choosing an electrode for the TIG process depends on the base material type and thickness and whether you weld with alternating or direct current.

This article will describe tungsten options, how to pick the best one for your application and proper tungsten preparation.

Pure tungsten (color code: green)

Note: Each electrode is “color coded” to eliminate confusion over its type. The color appears at the tip of each electrode.

Pure tungsten electrodes (AWS classification EWP) contain 99.50% tungsten, have the highest consumption rate of all electrodes and are typically less expensive than “alloyed” counterparts.

These electrodes form a clean, balled tip when heated and provide good arc stability for AC welding with a balanced waveform. Pure tungsten also provides good arc stability for AC sine wave welding, especially on aluminum and magnesium, but is not used for DC welding (it does not provide as strong of arc starts as thoriated or ceriated electrodes).

2% thoriated (color code: red)

2% thoriated tungsten electrodes (AWS classification EWTh-2) contain a minimum of 97.30% tungsten and 1.70 to 2.20% thorium. They are the most commonly used electrodes today and are preferred for their longevity and ease of use. Thorium increases the electron emission qualities of the electrode, which improves arc starts and allows for a higher current carrying capacity. This electrode operates far below its melting temperature, which results in a considerably lower rate of consumption and minimizes arc wandering for greater stability. It also features a lower level of weld contamination than other electrodes.

These electrodes can be used for AC welding, and they are exceptional for DC electrode negative (straight polarity) on carbon and stainless steel, nickel and titanium applications.

During manufacturing, thorium is evenly dispersed throughout the electrode. This evenness allows the electrode to maintain a sharpened edge — the ideal electrode shape for welding thin steel. Sharpening the electrode’s point, however, should be done with great care. Thoriated tungsten contains low levels of radioactivity. Therefore, you must always follow manufacture’s warnings, instructions and the MSDS (Material Safety Data Sheet) for its use.

2% ceriated (color code: orange)

2% ceriated tungsten electrodes (AWS classification EWCe-2) contain a minimum of 97.30% tungsten and 1.80 to 2.20% cerium. These electrodes perform best in DC welding but can be used proficiently in AC or DC processes. With its excellent arc starts at low amperages, ceriated tungsten has become popular in such applications as orbital tube and pipe manufacturing, thin sheet metal work or jobs where small and delicate parts are welded. Like thorium, it is best used to weld carbon and stainless steels, nickel alloys and titanium, making it an obvious replacement for 2% thoriated electrodes. Ceriated tungsten features slightly different electrical characteristics than thorium but most operators won’t be able to tell the difference.

Newer methods of welding AC on Aluminum include using pointed Ceriated tungsten. This tungsten when pointed starts very well while providing 30 to 40% more current carrying capacity than the same diameter pure tungsten, and does not contain any radioactive materials

1.5% lanthanated (color code: gold)

1.5% lanthanated tungsten electrodes (AWS classification EWLa-1.5) contain a minimum of 97.80% tungsten and 1.30 to 1.70% lanthanum, or lanthana. These electrodes have excellent arc starting, low-burn-off rate, good arc stability and excellent re-ignition characteristics — many of the same advantages as ceriated electrodes. 1.5% lanthanated electrodes also closely resemble the conductivity characteristics of 2% thoriated tungsten, meaning, in some cases, it can replace 2% thoriated without having to make significant welding program changes.

[pullquote]1.5% lanthanated tungsten electrodes are ideal if you want to optimize your welding capabilities. Lanthanated electrodes work well on AC or DC electrode negative with a pointed end or they can be balled for use with AC sine wave power sources. The lanthana is dispersed evenly throughout the entire length of the electrode during manufacturing. It also maintains a sharpened point well, which is an advantage for welding steel and stainless steel on DC or the AC from squarewave power sources.

These electrodes are suitable for AC welding and, like ceriated electrodes, allow for the arc to be started and maintained at lower voltages AC. Compared to pure tungsten, the addition of 1.5% lanthana increases the maximum carrying capacity by approximately 50% for a given size electrode.

Zirconiated (color code: brown)

Zirconiated tungsten electrodes (AWS classification EWZr-1) contain a minimum of 99.10% tungsten and .15 to .40% zirconium. A Zirconiated tungsten electrode produces an extremely stable arc and resists tungsten spitting. It is ideal for AC welding as it retains a balled tip and has a high resistance to contamination. Its current carrying capability is equal to or greater than thoriated tungsten. Under no circumstances is zirconiated recommended for DC welding.

Rare earth (color code: gray)

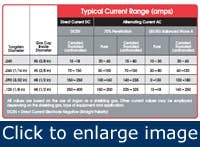

Figure 1: Typical current ranges for electrodes with argon shielding.

Rare earth tungsten electrodes (AWS classification EWG) contain unspecified additives of rare earth oxides or hybrid combinations of different oxides, but manufacturers are required to identify each additive and its percentage on the package. Depending on the additives, desired results can include: a stable arc in both AC and DC processes, greater longevity than thoriated tungsten, the ability to use a smaller size diameter tungsten for the same job, use of a higher current for similar sized tungsten and less tungsten spitting.

Tungsten preparation — balled, pointed or truncated?

A balled tip is generally used on a pure tungsten electrode and is suggested for use with the AC process on sine wave and conventional squarewave TIG welders. To properly ball the end of the tungsten, simply apply the AC amperage recommended for a given electrode diameter (see Figure 1) and the ball on the end of the tungsten will form itself. The diameter of the balled end should not exceed 1.5 times the diameter of the electrode (for example, a 1/8-in. electrode should form a 3/16-in. diameter end), as having a larger sphere at the tip of the electrode can reduce arc stability and/or fall off and contaminate the weld.

Figure 2: Preparing tungsten for DC electrode negative welding and AC with wave shaping power sources.

A pointed and/or truncated tip (for pure tungsten, ceriated, lanthanated and thoriated types) should be used for inverter AC and DC welding processes. To properly grind the tungsten, use a grinding wheel specially designated for tungsten grinding (to avoid contamination) and one that is made of borazon or diamond (to resist tungsten’s hardness). Note: if you are grinding thoriated tungsten, make sure you control and collect the dust, have an adequate ventilation system at the grinding station and that you follow manufacture’s warnings, instructions and MSDS.

Grind the tungsten straight on the wheel versus at a 90-degree angle (see figure 2) to ensure that the grind marks run the length of the electrode. Doing so reduces the presence of ridges on the tungsten that could create arc wandering or melt into the weld puddle, causing contamination.

Generally, you will want to grind the taper on the tungsten to a distance of no more than 2.5 times the electrode diameter (for example, with a 1/8-in. electrode you would grind a surface 1/4 to 5/16-in. long). Grinding the tungsten to a taper eases the transition of arc starting and creates a more focused arc for better welding performance.

When welding with lower currents on thinner materials (those ranging from .005- to .040-in.), it is best to grind the tungsten to a point. A pointed tungsten allows the welding current to transfer in a focused arc and helps prevent thinner metals, such as aluminum, from becoming distorted. As a note, using pointed tungsten for higher current applications is not recommended, as the higher current can blow off the tip of the tungsten and cause weld puddle contamination.

Instead, for higher current applications, it is best to grind your tungsten to a truncated tip. To achieve this shape, first grind the tungsten to a taper as explained above, then grind a .010- to .030-in. flat land on the end of the tungsten. This flat land helps prevent the tungsten from being transferred across the arc and/or from balling.

Conclusion

In any application, the type and shape of tungsten you use helps determine the arc quality and welding performance you will achieve. Each of the six types of tungsten discussed here bring with it distinct advantages and disadvantages. That’s why, regardless of type of material you are TIG welding or whether you are using an AC or DC process, it is always important to choose your tungsten wisely for each application. Doing so can maximize your TIG welding success and is one of the best defenses against contamination and rework. For more information, visit Weldcraft at www.weldcraft.com.