Nonlinear loads have a major impact on an electric system

The motor current still contains the reactive elements, but the pulse width modulated (PWM) drive supplies that reactive current without passing it back to the distribution system. Because the input to a PWM drive requires no reactive current, a problem exists if capacitors for power factor correction are installed on the same distribution system that the drive is using. Capacitors for power factor correction, rated in kVAR, are selected on the basis of the reactive needs of the circuit. These capacitors cannot control how much reactive current flows in the system. They are slaves to the needs of reactive components, such as motors. When using any drive to control the motor, the capacitors have to work harder to supply the real current--kVA requirements--of the load. It is not harmonics that overwork power factor correction capacitors. It is the change from kVAR to kVA that causes more current to flow through the capacitors. If an AC drive controls the motor, remove the capacitors from the system. If the distribution system powers fixed-speed and variable-speed motors, the capacitors must be at least 250 electrical feet from the input of any drive. Adding inductance between the capacitors and the input of any drive reduces the current demand.

A practical review of power quality

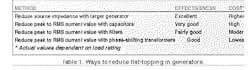

Power quality covers a wide variety of issues. For most equipment, the term "power quality" applies when variations in utility power affect the user's process. For most motors controlled by drives, power quality issues involve too much voltage, too little voltage or momentary loss of voltage. For other equipment, power quality is defined as variations in voltage (shown in Figure 1). Voltage quality conditions arise when nonlinear loads, such as welders, electric arc furnaces, uninterruptible power supplies, DC drives and current source drives, demand power from a distribution system with a large series impedance. Generators typically have significantly more series impedance than a utility or facility transformer. In cases of a generator rated at less than four times the rating of the connected nonlinear loads, one must take special care to prevent the generator voltage waveform from becoming distorted. PWM AC drives distort the voltage waveform less. The waveform distortion is limited to flat-topping of the voltage sine wave as compared with voltage-notching and distortion near the zero crossover point of the voltage waveform. Adding line reactors between the generator and the nonlinear loads aggravates the problem for every type of nonlinear load. When applying PWM AC drives--the most common type of AC drive--the flat-topping can be improved using some basic approaches.

When using PWM drives, current only flows during a portion of each half cycle. For a given RMS value, peak current is greater than for a normal current sine wave that drives a current flow during the full half cycle. This larger peak value causes a greater voltage drop within the generator. There are a few ways to reduce the flat-topping. One approach is to increase the size of the generator so that the actual voltage drop across the internal impedance of the generator is small. This is the highest cost solution.

The other approach is to reduce the peak to the root mean square (RMS) value of the demand or load current. There are a number of methods to accomplish that reduction. The first and most costly method of reducing flat-topping would be to add capacitors at the terminals of the generator. The capacitors must be sized to handle the expected load current or kVA of the load. A second, and less costly, method would be to add a filter (a small series inductance and shunt capacitance) rated for the expected kVA load. Some filters are designed to supply peak load current while the generator sine wave voltage is at the peak value. These capacitors are "recharged" when the generator is not supplying current to the load.

The third, lowest cost method is to divide the nonlinear loads into groups that take power from separate voltage sources. Adding a transformer between the generator and the loads provides this voltage separation. The transformer needs two secondary windings. One winding, configured as a wye or star, supplies the voltage for one load group. The other winding, configured as a delta, supplies the voltage for the other load group and is phase-shifted from the first winding by 30 degrees. Phase-shifting the voltage sources decreases the peak RMS value and reduces flat-topping of the generator terminal voltage. Because the current pulses for each load group are displaced in time, the RMS value of current increases but the peak values do not add. Additional load groupings and phase shifts continue to reduce the peak current. The no-load losses of the transformer must be considered as part of the total load on the generator. It is important to remember that line-to-line variations result in unbalanced phase currents. If too great a voltage imbalance exists, then the highest line-to-line voltage experiences the highest RMS and peak current so flat-topping will persist.

Most problems in nonlinear equipment occur when the voltage is too high or too low. The time during which the voltage is too high or too low ranges from a few microseconds to a few milliseconds. Although actual equipment damage is limited when problems occur, nuisance-tripping can affect production.

Unlike linear equipment, continued operation under these operating conditions may not be achievable. When the fault occurs on the line, the voltage decreases to a value sustained by the facility. After the fault has been removed, magnetic fields created by the fault current collapse and generate a momentary high voltage. More often than not, the only solution to a nuisance trip is to restart the equipment. If process interruption is too costly, consider a secondary power source. Most PWM AC drives can be used with secondary power sources without the need for major equipment redesign. For too much voltage, voltage suppression or equipment isolation is the only practical solution. For momentary loss of voltage, most PWM AC drives have a power loss ride-through capability. This feature allows the logic control to continue operating. However, power is momentarily disconnected from the motor and reconnected when the voltage recovers from the under-voltage condition. The duration of the momentary power loss varies on the basis of the actual load conditions that need to be sustained. A few cycles of lost power may allow recovery without seriously affecting the user process. Some processes will not tolerate any loss of power and should be reviewed as candidates for a secondary power source.

Harmonics and power quality are too often explained using confusing technical jargon. Focusing on the RMS and peak values for voltage and current provides insight into how to deal with potential problems. Maintaining the RMS and peak values within the tolerances set for electronic equipment prevents most electrical problems. Perform power quality audits at least four times per year. An audit can be as simple as observing actual voltage waveforms with an oscilloscope and recording the RMS and peak values for voltage and current at various points in a distribution system. Depending solely on measurements that provide percent distortion data only leads to confusion, additional expense for unnecessary filtering equipment and does nothing more than create pretty waveforms.